Automation and process control engineering

With the aid of automation and process control engineering, processes are monitored and influenced as they happen. This is enabled by the measurement and control of variables such as flow rate, pressure, temperature, and concentration.

To control processes, first of all it is necessary to record the process variables. The different properties of the process variables, but also of the substances used and the respective aggregate states, make different measuring methods necessary. The different measuring methods can be illustrated in a simple way using the instructional units selected here.

Familiarisation with different industry standard components with a 4-20mA current loop interface using the example of level measurement

Learning objectives/experiments

- familiarisation with different level sensors

- familiarisation with different industry-standard components with a 4…20 mA current-loop interface

- connection and practical handling of components with a 4…20 mA 2-wire interface in a current loop

Familiarisation with key sensors: mode of operation and application

Learning objectives/experiments

- mode of operation and application of different sensors

- one-way photoelectric barrier

- reflex photoelectric barrier

- inductive proximity switch

- capacitive proximity switch

….

Basic introduction to measurement with strain gauges for tension, bending and torsion

Learning objectives/experiments

- fundamentals of measuring with strain gauges

- strain gauge types and application techniques

- calculation of the mechanical deformations under tension, bending and torsion

- correlation between mechanical strain and electrical resistance in a strain gauge

- with FL 100.01, FL 100.02, FL 100.03: determination of the modulus of elasticity for various materials from the measuring data of a tensile test

Experimental introduction to temperature measurement: methods, areas of application, characteristics

Learning objectives/experiments

- learning the fundamentals of temperature measurement by experimentation

- familiarisation with the various methods, their areas of application and special features

- non-electrical methods: gas- and liquid-filled thermometers, bimetallic thermometers and temperature measuring strips

- electrical methods: thermocouple, resistance thermometer Pt100, thermistor (NTC)

- determining air humidity with a psychrometer

….

Test-pressure generated with dead-weight piston manometer

Learning objectives/experiments

- familiarisation with, and carrying out of the calibration of an electronic pressure sensor

- plotting the sensor output signal dependent on the pressure applied

- familiarisation with the design and operation of a piezo-resistive electronic pressure sensor

- familiarisation with the installation and connection of the pressure sensor

- information on applications, measuring ranges and accuracies of typical electronic pressure sensors

Comparison and calibration of different flow meters

Learning objectives/experiments

- together with different flow meters available as accessories

- different flow meters and their principles of operation

- calibration of different flow meters

- position dependency of flow meters

- plotting and comparison of pressure loss curves

Actuators are key components of process engineering systems. They create a link between the controller and the system. Optimum control loop design depends on a sound knowledge of actuator behaviour as well as knowledge of the controlled system response.

Maintenance and operational check: four different fittings and actuators

Learning objectives/experiments

- function and mode of operation of various valves and fittings

- pneumatic butterfly valve

- pneumatic segmented ball valve

- pneumatic control valve with electro-pneumatic

- positioner

….

Recording characteristic curves of industrial fittings and a centrifugal pump

Learning objectives/experiments

- characteristics of a centrifugal pump

- behaviour during operation and function of

- ball valve

- butterfly valve

- shut-off valve

….

Design and function of control valves; determination of the Kv value

Learning objectives/experiments

- together with control valves RT 390.01 – RT 390.06

- demonstration and functional testing of control valves

- determination of Kv and Kvs values

- plotting valve characteristics

- dynamic response of control valves: plotting step responses

….

Design and function of a pneumatically driven control valve; planning, assembly and disassembly

Learning objectives/experiments

- function and design of a pneumatically driven control valve

- planning and presentation of the assembly process

- assembly and disassembly, including for the purposes of maintenance and repair

- read and understand engineering drawings (PDF files, DXF files, STEP files)

- familiarisation with different file formats and their application, e.g. for 3D printing and CNC machining

….

Design and function of an electrically driven control valve; planning, assembly and disassembly

Learning objectives/experiments

- function and design of an electrically driven control valve

- planning and presentation of the assembly process

- assembly and disassembly, including for the purposes of maintenance and repair

- read and understand engineering drawings (PDF files, DXF files, STEP files)

- familiarisation with different file formats and their application, e.g. for 3D printing and CNC machining

….

Nowadays most industrial processes are automated. Process controllers are at the heart of the automation of process applications. State-of-the-art digital process controllers offer a level of functionality which would have been inconceivable some years ago. Alongside extensive configuration and parameter setting functions to adapt to the control task, they also permit interconnected networking. Thus, process automation by way of centralised process control systems or distributed control systems (DCS) is possible. This range of equipment provides a step-by-step introduction to process automation and process control engineering based on process controllers and field bus systems.

Accessory for selected GUNT devices enables practice-oriented distance teaching and learning: experiment observation via web browser with streaming of live images

Learning objectives/experiments

- together with Web Access Software:

Remote learning – Web Access Box as server, access via web browser irrespective of the system- display of the process schematic

- display of the switching states

- display of all current measured values

….

Simulation of controlled systems; digital controller with freely selectable parameters

Learning objectives/experiments

- basic concept of an industrial controller

- operator control levels

- parameter level

- configuration level

- learning about basic terminology and methods of process control

….

Tuning the controller to the controlled system; software simulation of the most common controlled systems

Learning objectives/experiments

- learning basic terminology and methods involved in process control

- control loop comprising controller and controlled system

- difference between open and closed loop control

- adapting the controller to different controlled systems

- determining the controlled system parameters

….

- determining the controlled system parameters

Comprehensive training courses in the fundamentals of hydraulic, pneumatic and electro-pneumatic controls

Complete training system providing an experimental introduction to the fundamentals of hydraulics

Learning objectives/experiments

- comprehensive experimental introduction to the fundamentals of hydraulic drive and control engineering

- familiarisation with terms and symbols

- representation of hydraulic circuits

- drive unit

- multi-way valves and drives

….

Hydraulic position control circuit with adjustable load conditions

Learning objectives/experiments

- familiarisation with the mode of operation of a hydraulic position control loop with adjustable load conditions

- reading and understanding circuit diagrams

- replacing springs and adjusting the damper

- influence of load and system pressure on control accuracy

- influence of the amplifier constants on the stability of the closed control loop

….

Complete training system providing an experimental introduction to the fundamentals of pneumatics and electro-pneumatics, also with PLC

Learning objectives/experiments

- physical principles of pneumatics and electro-pneumatics

- fundamentals of, and terms used in, process control

- design and function of pneumatic components

- logic elements, logic diagram

- multi-way valves, pressure, shut-off and flow control valves

….

Set of electrohydraulics components for hydraulics trainer RT 700

Learning objectives/experiments

- together with RT 700, the following experiments are possible (among others)

- locking

- sequence control

- hold a load

- experimental components

….

Every component of a control loop exhibits a complex behaviour. This behaviour significantly influences the quality of the control process. It is therefore necessary to calibrate the key components of a control loop.

Investigation of the transmission behaviour of actuators and transducers

Learning objectives/experiments

- together with the accessory control loop components

- mode of operation of control loop components: transducers, actuators, controllers

- familiarisation with different signals: pneumatic, electrical

- correct connection of control loop components

- transmission behaviour of control loop components

….

Calibration of control loop components using precision measuring technique

Learning objectives/experiments

- together with the accessory control loop components

- mode of operation of control loop components: transducers, actuators, controllers

- familiarisation with different signals: pneumatic, electrical

- correct connection of control loop components

- transmission behaviour of control loop components

Systems in which only one variable is controlled are ideally suited to introduce students to the subject matter. Much emphasis was placed on the use of industrial components in the development of these control systems. This enhances the practical relevance and industrial applicability of these systems. These are simple control loops. The components can be easily identified visually and assigned to their respective functions.

Fundamentals of control engineering using the example of a level control system with integral behaviour

Learning objectives/experiments

- fundamentals of control engineering using the example of a level controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Fundamentals of control engineering using the example of a rapid flow control system

Learning objectives/experiments

- fundamentals of control engineering using the example of a flow controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Fundamentals of control engineering using the example of a pressure control system with first order lag

Learning objectives/experiments

- fundamentals of control engineering using the example of a pressure controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Fundamentals of control engineering using the example of a temperature control system with lag time

Learning objectives/experiments

- fundamentals of control engineering using the example of a temperature controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Fundamentals of control engineering using the example of a speed control system with first order lag

Learning objectives/experiments

- fundamentals of control engineering using the example of a speed controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Fundamentals of control engineering using the example of a position control system with integral behaviour

Learning objectives/experiments

- fundamentals of control engineering using the example of a position controlled system

- open control loop response

- controlled system without feedback

- effects of different controller parameters and methods on the closed loop system response

- controller optimisation by changing the controller parameters: Kp, Tn, Tv

….

Level controlled system based on standard industrial components, smart level sensor, system control via PLC

Learning objectives/experiments

- design and function of a level control system

- investigate the properties of open and closed loops

- investigate disturbance and reference variable response

- manipulating variable limitation and effect on the control system

- fault finding (fault simulation via PLC)

….

Flow controlled system based on standard industrial components, smart flow rate sensor, system control via PLC

Learning objectives/experiments

- design and function of a level control system

- investigate the properties of open and closed loops

- investigate disturbance and reference variable response

- manipulating variable limitation and effect on the control system

- fault finding (fault simulation via PLC)

….

First order and second order pressure controlled system based on standard industrial components, smart pressure sensors, system control via PLC

Learning objectives/experiments

- design and function of a pressure control system

- investigate the properties of open and closed loops

- control response in

- 1st order controlled system

- 2nd order controlled system

….

Temperature controlled system based on standard industrial components, controller configurable as a continuous or a switching device, smart temperature sensors, system control via PLC

Learning objectives/experiments

- design and function of a temperature control

- investigate the properties of open and closed loops

- control response in

- continuous control

- two-point control

….

pH value controlled system based on standard industrial components, smart pH sensors, system control via PLC

Learning objectives/experiments

- design and function of a pH control system

- investigate the properties of open and closed loops

- investigate disturbance and reference variable response

- manipulating variable limitation and effect on the control system

- fault finding (fault simulation via PLC)

….

Experimental introduction to control engineering using an example of level controlled system

Learning objectives/experiments

- fundamentals of control engineering

- latest industrial control engineering components: controllers, transducers, actuators

- operation and parameter setting of a multifunctional state-of-the-art digital controller: e.g. parameter setting as P, PI and PID controller

- investigation of disturbance and control response

- influence of different controller parameters on stability and control quality

….

Experimental introduction to control engineering using an example of flow controlled system

Learning objectives/experiments

- fundamentals of control engineering

- latest industrial control engineering components: controllers, transducers, actuators

- operation and parameter setting of a multifunctional state-of-the-art digital controller: e.g. parameter setting as P, PI and PID controller

- investigation of disturbance and control response

- influence of different controller parameters on stability and control quality

….

Experimental introduction to control engineering using an example of second order pressure controlled system

Learning objectives/experiments

- fundamentals of control engineering

- latest industrial control engineering components: controllers, transducers, actuators

- operation and parameter setting of a multifunctional state-of-the-art digital controller: e.g. parameter setting as P, PI and PID controller

- investigation of disturbance and control response

- influence of different controller parameters on stability and control quality

….

Experimental introduction to control engineering using an example of temperature controlled system

Learning objectives/experiments

- fundamentals of control engineering

- latest industrial control engineering components: controllers, transducers, actuators

- operation and parameter setting of a multifunctional state-of-the-art digital controller: e.g. parameter setting as P, PI and PID controller

- investigation of disturbance and control response

- influence of different controller parameters on stability and control quality

….

Experimental introduction to control engineering using an example of a control led system for flow rate, level and level via flow rate (cascade control)

Learning objectives/experiments

- fundamentals of control engineering

- latest industrial control engineering components: controllers, transducers, actuators

- operation and parameter setting of a multifunctional state-of-the-art digital controller: e.g. parameter setting as P, PI and PID controller

- investigation of disturbance and control response

- influence of different controller parameters on stability and control quality

….

RT 450 offers you a flexible and versatile learning platform to provide school and college students with a practical introduction to a wide range of topics and issues in the field of process automation. The close interlinking of practical skills with theoretical/analytical aspects promotes thorough learning. You can teach systematically categorised learning content or just as well combine complex material into integrated project work.

Basis for the modular setup of the different process automation experiments, including electrical power supply and water supply with tank and pump

Learning objectives/experiments

- together with accessory components, the following learning content and exercises are possible

- planning and construction of different process applications

- planning and construction of different automation solutions for the control systems

- familiarisation with the design, function and behaviour of industrial automation components, such as controllers, PLCs, actuators and measuring devices

- commissioning and optimisation of automated process applications

….

Together with further components this is the main element for the set-up of a level control loop

Learning objectives/experiments

- setting up a level control loop

- comparison of different sensors for level measurement

- level control against trapped-air cushion

- level / flow cascade control (with RT 450.02)

Together with further components this is the main element for the set-up of a flow control loop

Learning objectives/experiments

- setting up of a flow control loop

- comparison of different sensors for flow measurement

- level / flow cascade control (with RT 450.01)

Together with further components this is the main element for the set-up of a pressure control loop

Learning objectives/experiments

- planning, setting up, testing, optimising and assessing pressure control loops with different objectives and components

- constructing a 1st order pressure control system

- constructing a 2nd order pressure control system

- design and function of different instrumentation and control components

- technical terminology and symbols in industrial control engineering

….

Together with further components this is the main element for the set-up of a temperature control loop

Learning objectives/experiments

- planning, setting up, testing, optimising and assessing temperature control loops with different objectives and components

- design and function of different instrumentation and control components

- technical terminology and symbols in industrial control engineering

- practical exercises: implementing process and signal lines

- commissioning and troubleshooting of process engineering systems

Basic processes of handling (robots), manufacturing (CNC machining), and control (PLC)

Realisation of an automated process in which a complete tensile test is carried out; collaborative robot (cobot) as a modern, high-quality industrial robot; part of GUNT DigiSkills

Learning objectives/experiments

- familiarisation with and development of process automation

- analyse a process

- identify automation potential

- generate solutions using creativity techniques (e.g. 635 Method, mind mapping, morphological box)

- compare and evaluate solutions, e.g. using “weighted point evaluation”

….

Programming the motor controller, adjusting the control parameters, checking the software and troubleshooting the device; part of the GUNT DigiSkills programme

Learning objectives/experiments

- programming the motor controller

- adjusting the control parameters

- testing the software

….

Two CNC machines, one robot and one magazine as the main elements; PLC and process control software for process monitoring in an automated manufacturing process

Learning objectives/experiments

- creating part data

- writing a CNC program

- programming an industrial robot, including teach-in

- programming a travel unit

- programming a PLC

….

A PLC (programmable logic controller) is essentially a computer adapted to the needs of industry. Its inputs and outputs are not designed for humans, but for use in the control of machines. Machine and operator interact solely by way of limit switches, momentary-contact switches or photoelectric switches.

Self-contained PLC module for basic exercises; also suitable for IA 210 and RT 800

Learning objectives/experiments

- familiarisation with a PLC

- familiarisation with the essential fundamentals such as

- Boolean algebra

- compiling statement lists

- interconnection diagrams and block diagrams

….

Basic system of automation: transporting and sorting workpieces

Learning objectives/experiments

- familiarisation with and analysis of an automated materials handling process

- understanding and analysis of the mechanical, pneumatic and electrical functions

- familiarisation with the symbols, terms and modes of representation of pneumatic and electrical function diagrams

- familiarisation with automation components: cylinders, solenoid valves, photoelectric proximity switches

- familiarisation with the use of a PLC

….

Experiments using PLC to control discontinuous mixing processes

Learning objectives/experiments

- planning and implementation of a PLC controlled mixing process

- familiarisation with terms and symbols

- presentation of circuits

- functionality test of all sensors and actuators

- sensitivity adjustment of the capacitive proximity switches

….

Normally, multiple variables need to be controlled at the same time in industrial production processes. Our devices therefore enable students to learn and understand the complex interrelations in a practical manner. Again, we of course only use real, industrial components to ensure a high practical relevance.

Control of level, flow rate, temperature and cascade control; plant control and configuration via touch screen and PLC

Learning objectives/experiments

- familiarisation with industrial control loop components

- setup, parameterisation and configuration on the controller

- optimisation of controller settings

- level control

- flow rate control

….

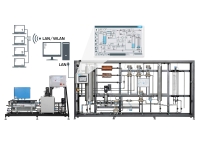

Complex industrial-scale experimental plant with large range of experiments; control of level, flow rate, pressure, temperature and cascade control, system control via PLC

Learning objectives/experiments

- familiarisation with industrial process engineering plant

- flow rate control

- level control with first order controlled system with and without counter pressure

- level control with second order controlled system

- cascade control of level and flow rate

….

Practical control of level, flow rate, pressure and temperature

Learning objectives/experiments

- familiarisation with industrial control loop components

- setup, parameterisation and configuration on the controller

- optimisation of controller settings

- flow rate control

- level control in closed tank with or without counter pressure

….

Control of pH value, redox potential, oxygen concentration and electrical conductivity

Learning objectives/experiments

- comparison of various controller types

- P, PD, PI and PID controllers

- two-point controller

- influence of caustic soda on electrical conductivity and pH value

- influence of sulphuric acid on pH value

….

Model of "degassing of fluids": coupled level and pressure control in one vacuum tank

Learning objectives/experiments

- coupled level and pressure control

- level control with various controller types

- pressure control with various controller types

- plotting step responses

Heated stirrer tank with heat recovery as model: coupled level and temperature control

Learning objectives/experiments

- coupled level and temperature control

- level control with

- PI controller

- feedforward control

- temperature control

….