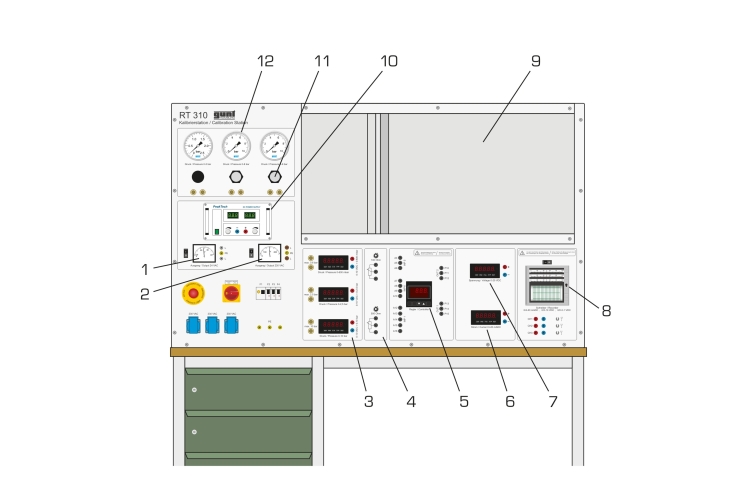

The calibration station is used in the investigation of the transmission behaviour of electrical and pneumatic control loop components. Electrical and pneumatic signals can be generated to effect actuation of the individual control loop components. A precision measuring technique facilitates the recording of the output signals from the control loop components. The supply of auxiliary power necessary for many control loop components is also provided.

Three pressure regulators with manometers are included to generate pneumatic signals. They can also be used to supply the components with auxiliary power. A power supply unit with adjustable voltage and current serves as the DC voltage source. Two switchable AC voltage sources supply auxiliary power. Two potentiometers can be used to simulate the behaviour of various devices such as resistance teletransmitters or motorized valves.

Three digital pressure gauges, a voltmeter, an ammeter and a 3-channel line recorder are provided for recording the output signals from the control loop components.

An industrial controller can be used to generate signals in the form of functions and to measure signals. It features three input channels and two output channels which are freely configurable. A separate high-grade universal calibrator further enhances the practical value of this unit. As an example, the calibrator facilitates the simulation of output signals from thermocouples and the measurement of the resulting output signal from a connected transducer.

Various control loop components such as transducers, control valves and controllers are available as accessories. They are inserted in the calibration station frame and connected by way of the supplied hoses and cables.