SE 200 Ι MEC Line

SE 200 Ι MEC Line

Engineering mechanics – digital & smart

The GUNT MEC Line intuitively combines mechanical experiments with digital teaching methods. This concept offers the perfect opportunity to introduce students to digital structures that are needed in today's working world, in parallel to the subject-specific learning objectives.

What is learned?

| Develop the fundamentals of engineering mechanics according to textbook and curriculum in experiments |  |

- static systems in equilibrium of forces

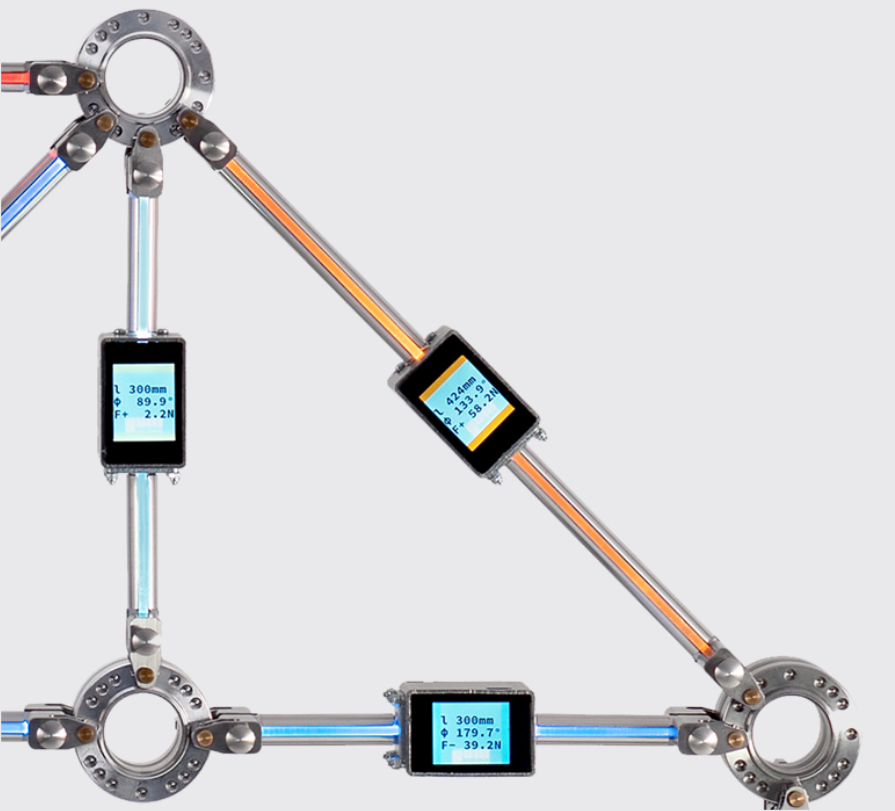

- trusses: internal reaction and support reaction under external loads

- elastic reactions under external loads

- analysis of typical elements from civil engineering: beams, bridges

- familiarisation with stability problems

How is it learned?

| Familiarisation with digital concepts and methods of measurement technology and data processing simultaneously |  |

- implement theoretical teaching topics in experiments by planning series of experiments and setting up your own experiments

- technically realise terms such as fixation or articulated support

- coloured display of forces, display of the loading as well as automatic topology transmission for direct feedback

- microprocessor-based measurement technology for force and angle, distance, position and identification

- application of Gray codes

- integration of FEM models, strength verification, etc.

Highlights of the MEC Line

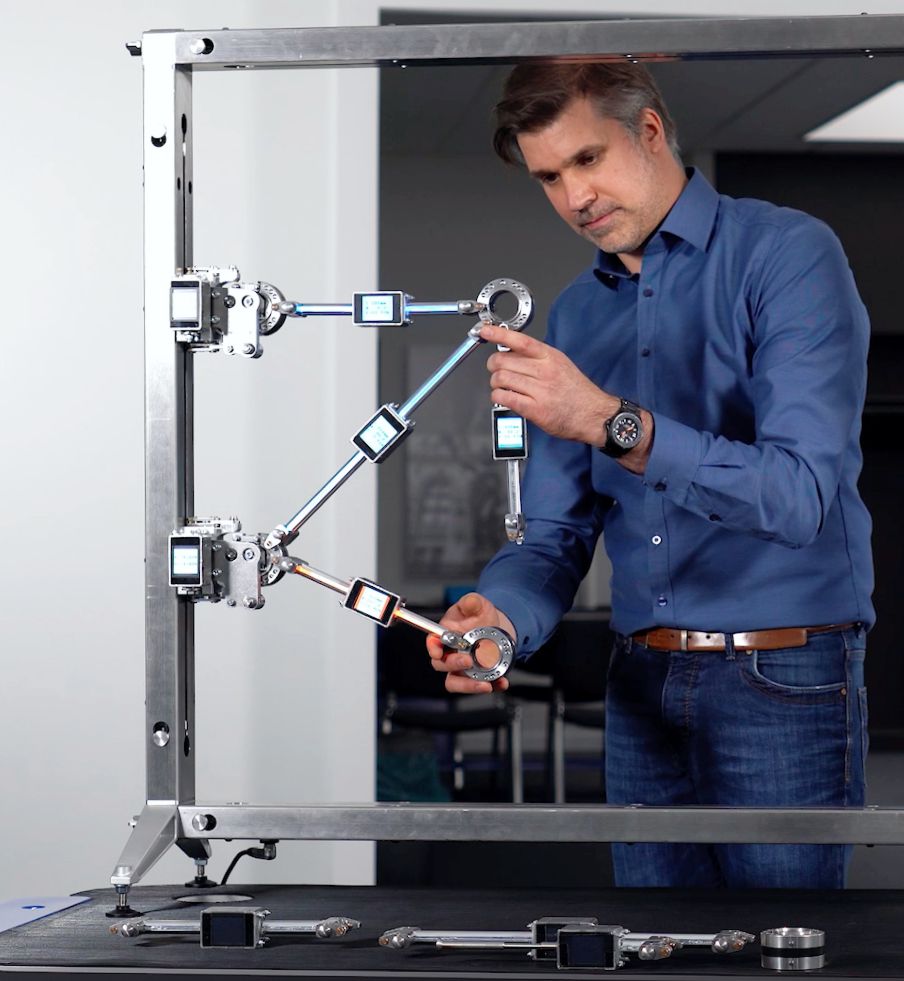

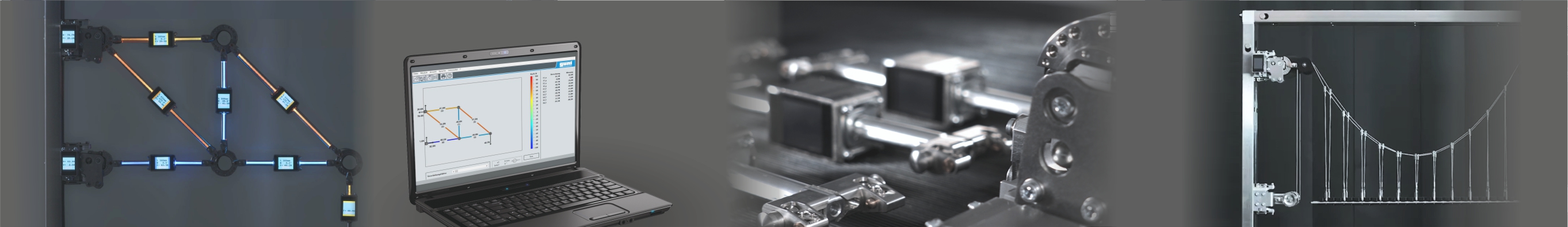

Experiments using all the senses – for an in-depth learning experience

The MEC Line offers a wide range of accessories for different experiments in the field of statics and strength of materials. All components are equipped with a click system and enable experiments with many variations. Thereby, experimental learning is targeted and haptic experiences are facilitated. The use of smart, communication-enabled components in combination with the GUNT software makes it easy to understand relations and stimulates visual comprehension and logical thinking.

Smart components

Smart components

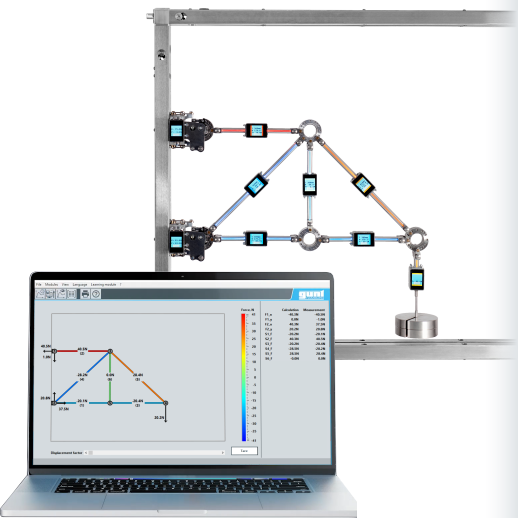

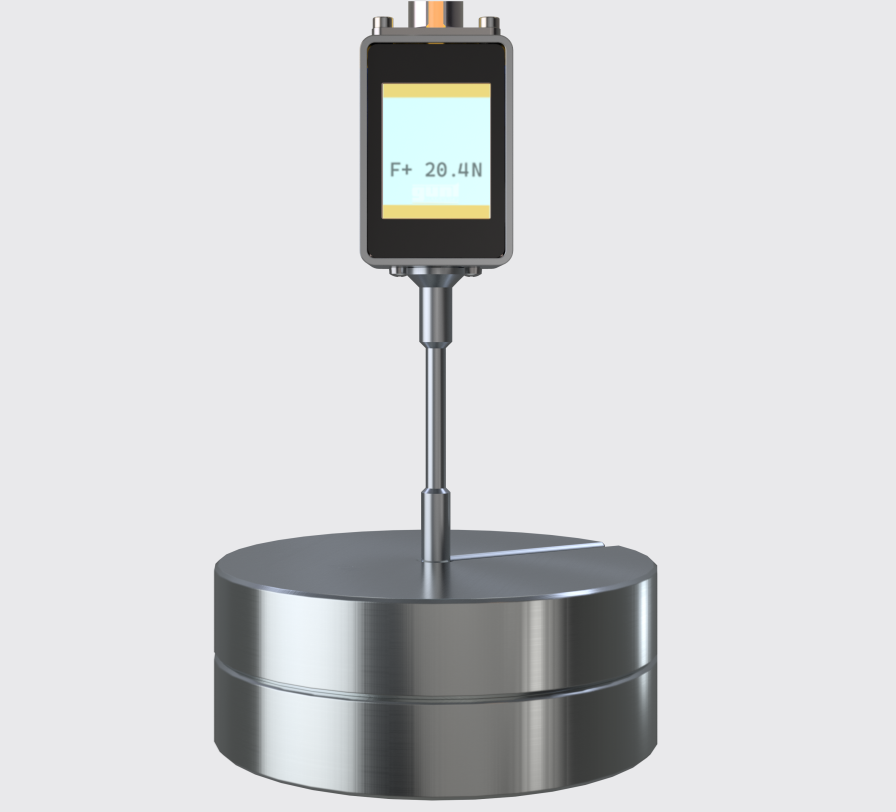

Smart, communication-enabled components with electronic module for direct data acquisition and measured value display. The measured forces are additionally displayed in colour directly on the bars.

Click system

Click system

Precise and resilient frame structure with precisely fitting quick-release fasteners. The click system enables a simple, quick experimental setup without cabling.

Plug&Play

Plug&Play

Only 1 power bus line to the experimental unit is required for power supply and data transmission. The mounting frame provides direct and wireless data transmission and power supply for the smart components.

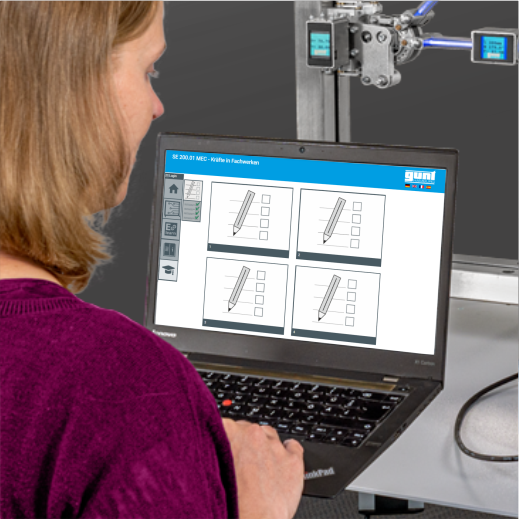

Software

Software

Custom GUNT software with content adapted to the individual experiments. The simultaneous transfer of measured values enables real-time display and analysis of the experiments.

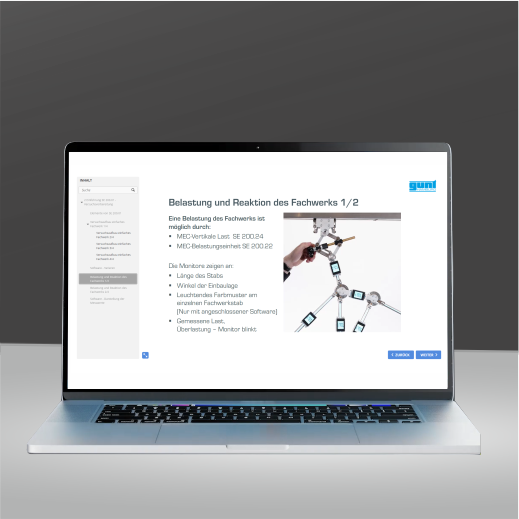

GUNT Science Media Center

GUNT Science Media Center

The GUNT Science Media Center provides extensive multimedia teaching material for all experiments. In addition to digital worksheets and the manual, access to E-Learning is also included.

E-Learning

E-Learning

The E-Learning presents fundamental knowledge and the experiment procedure in detail with engaging animations. Knowledge tests facilitate understanding.

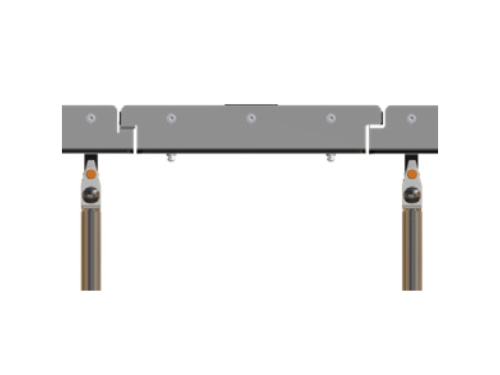

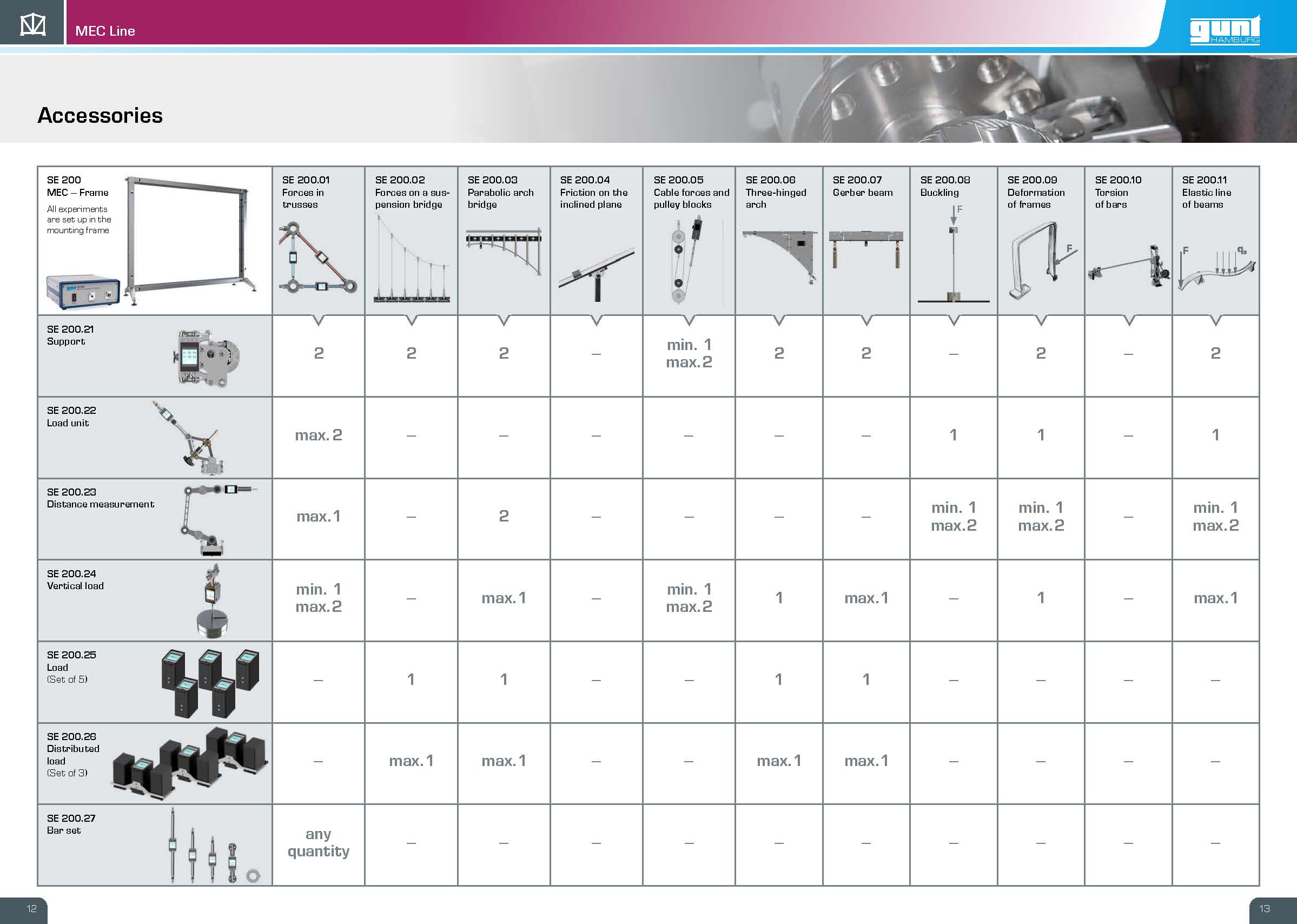

Setup and combination

A complete experimental setup is created from the mounting frame (SE 200), the components for experiments (SE 200.01 - SE 200.11) and the components for the setup and measurement technology (SE 200.21 - SE 200.27). Accessories of the series can be combined in a modular way and allow setup and extension of the experiments.

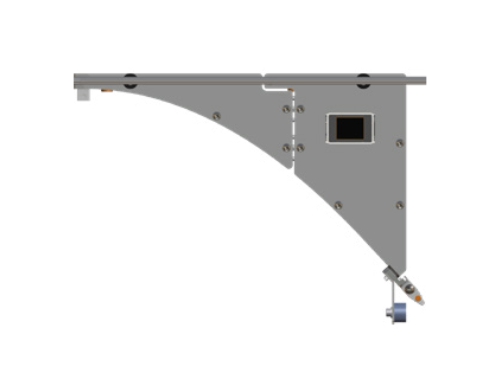

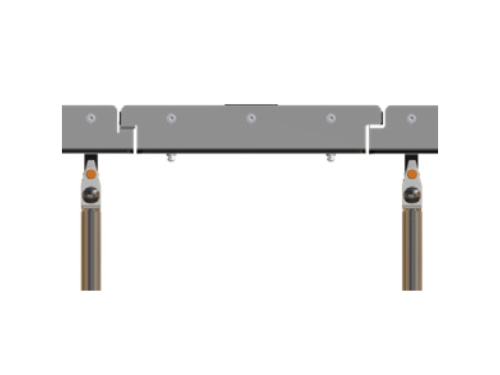

Mounting frame

Mounting frame

- base element for setting up versatile experiments

- click system for easy setup and reconfiguration, no tools required

- stainless steel hollow sections with integrated electrical cable

- defined snap-in points for exact topology determination and transmission topology determination and transmission

Master module

- master module detects all data from the electronic modules and transmits it to the GUNT software via USB

- automatic identification of the smart, communication-enabled components including position and alignment

- master module connected via Plug&Play and only 1 power BUS line

Components for experiments as accessories

Measurement of bar forces; comparison of forces in statically determinate and statically indeterminate trusses

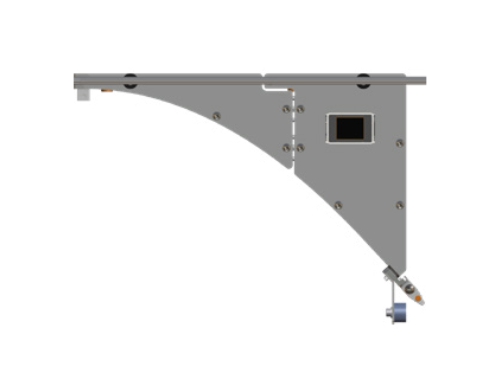

» About the productMEC - Forces on a suspension bridge

Supporting cable force and demonstration of bending moments between the roadway support and supporting cables; experiments with rigid or flexible roadway

» About the productSE 200.03

MEC - Parabolic arch bridge

Arched bridge with supporting arch below the roadway; differences between statically determinate and statically indeterminate arches under load

SE 200.04

MEC - Friction on the inclined plane

Sliding and static friction for different pairs of materials; angle of plane adjustable

MEC - Cable forces and pulley blocks

Construction and mode of operation of twodifferent pulley blocks; 2 setup variants possible for each

» About the productSE 200.06

MEC - Three-hinged arch

Experiments with symmetric or asymmetric three-hinged arch; measurement of support forces and resultant moment for different loads

SE 200.07

MEC - Gerber beam

Gerber beam with two cantilevers and a suspended beam between them; experiments with different loads and support positions

SE 200.08

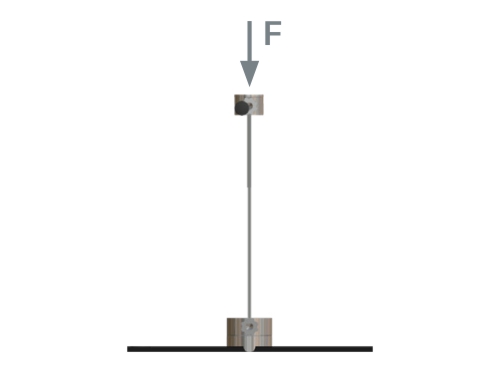

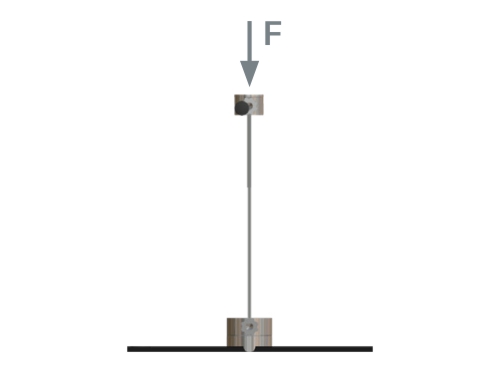

MEC - Buckling

Determination of buckling load and deflection; influence of support, cross-section, material

SE 200.09

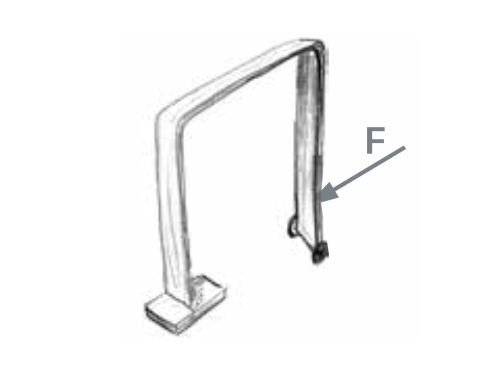

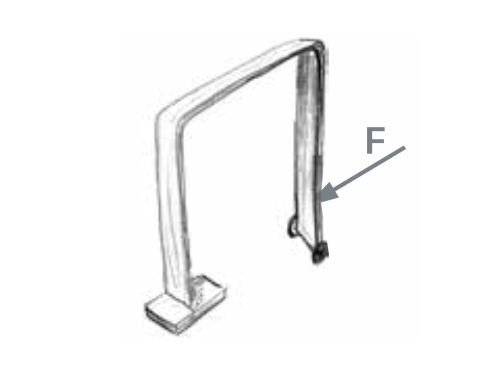

MEC - Deformation of frames

Measurement of deformation for different loads and support

SE 200.10

MEC - Torsion of bars

Measurement of the angle of twist and torque for different specimens

SE 200.11

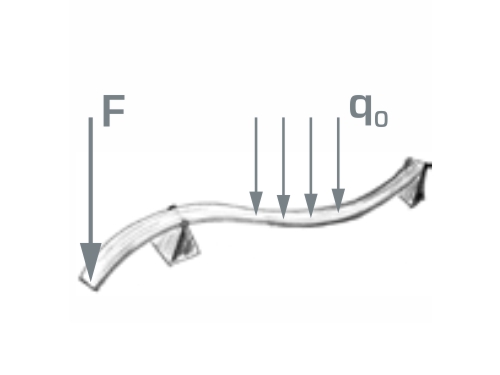

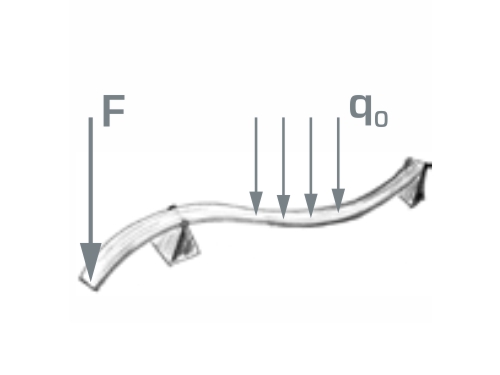

MEC - Elastic line of beams

Determination of the elastic line for different loads; comparison of different methods

Components for assembly and measurement as accessories

Support with electronic module for data acquisition and measured value display; Messung von Kräften in x- und y-Richtung

» About the product

Load unit with electronic module for data acquisition and measured value display; measurement of force and loading angle

» About the product

Distance measurement with electronic module for data acquisition and measured value display; automatic transmission of the measurement direction

» About the product

Load with electronic module for data acquisition and measured value display; different weights to generate vertical loads

» About the product

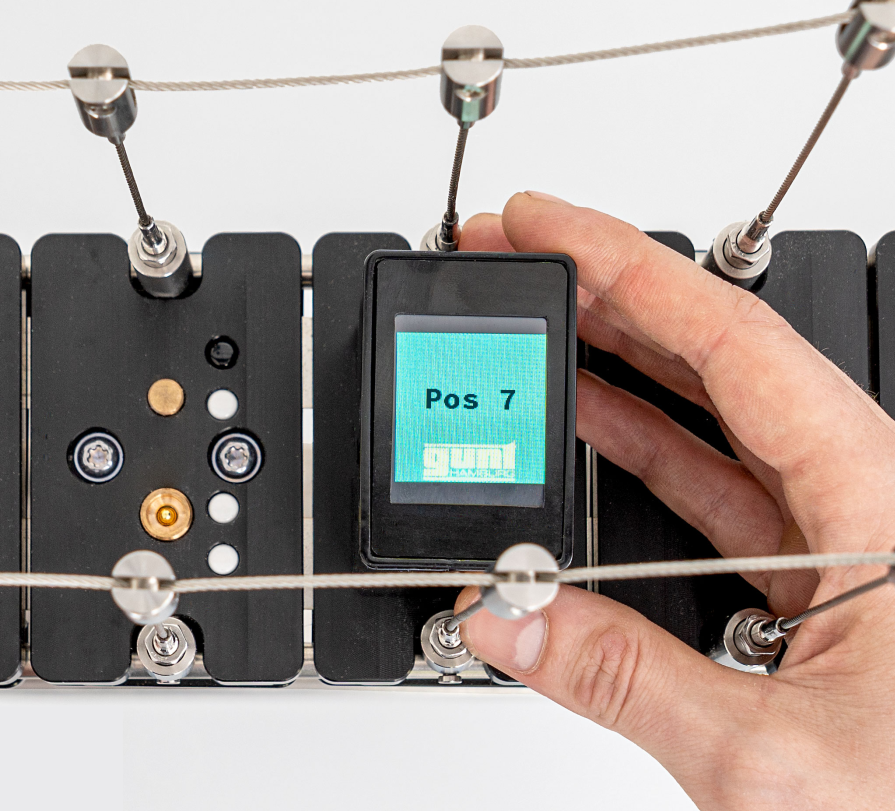

Load with electronic module for data acquisition and measured value display; position detected via Gray code reader

» About the product

Distributed load with electronic module for data acquisition and measured value display; position detected via Gray code reader

» About the product

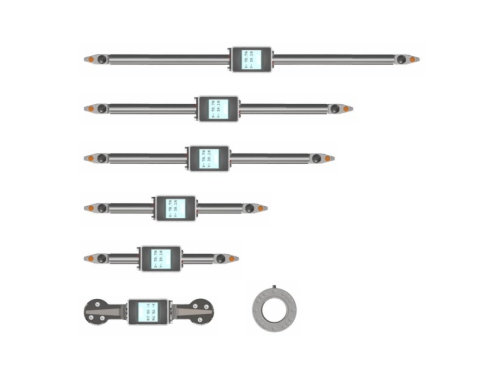

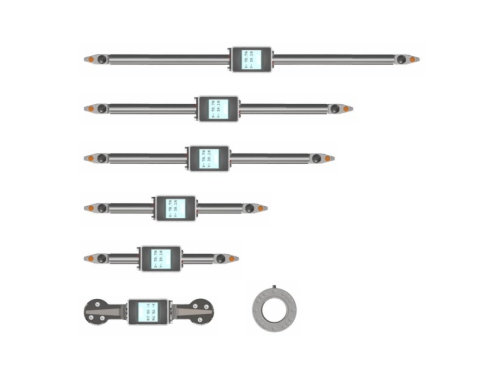

Bars with electronic modules for data acquisition and measured value display; used to extend trusses in SE 200.01

» About the product

Mounting frame

Mounting frame

- base element for setting up versatile experiments

- click system for easy setup and reconfiguration, no tools required

- stainless steel hollow sections with integrated electrical cable

- defined snap-in points for exact topology determination and transmission topology determination and transmission

Master module

- master module detects all data from the electronic modules and transmits it to the GUNT software via USB

- automatic identification of the smart, communication-enabled components including position and alignment

- master module connected via Plug&Play and only 1 power BUS line

Components for experiments as accessories

|

Measurement of bar forces; comparison of forces in statically determinate and statically indeterminate trusses |

|

|

Supporting cable force and demonstration of bending moments between the roadway support and supporting cables; experiments with rigid or flexible roadway |

|

|

SE 200.03 MEC - Parabolic arch bridge |

|

Arched bridge with supporting arch below the roadway; differences between statically determinate and statically indeterminate arches under load |

|

SE 200.04 MEC - Friction on the inclined plane |

|

Sliding and static friction for different pairs of materials; angle of plane adjustable |

|

Construction and mode of operation of twodifferent pulley blocks; 2 setup variants possible for each |

|

|

SE 200.06 MEC - Three-hinged arch |

|

Experiments with symmetric or asymmetric three-hinged arch; measurement of support forces and resultant moment for different loads |

|

SE 200.07 MEC - Gerber beam |

|

Gerber beam with two cantilevers and a suspended beam between them; experiments with different loads and support positions |

|

SE 200.08 MEC - Buckling |

|

Determination of buckling load and deflection; influence of support, cross-section, material |

|

SE 200.09 MEC - Deformation of frames |

|

Measurement of deformation for different loads and support |

|

SE 200.10 MEC - Torsion of bars |

|

Measurement of the angle of twist and torque for different specimens |

|

SE 200.11 MEC - Elastic line of beams |

|

Determination of the elastic line for different loads; comparison of different methods |

Components for assembly and measurement as accessories

|

Support with electronic module for data acquisition and measured value display; Messung von Kräften in x- und y-Richtung | |

|

Load unit with electronic module for data acquisition and measured value display; measurement of force and loading angle | |

|

Distance measurement with electronic module for data acquisition and measured value display; automatic transmission of the measurement direction | |

|

Load with electronic module for data acquisition and measured value display; different weights to generate vertical loads |

|

|

Load with electronic module for data acquisition and measured value display; position detected via Gray code reader |

|

|

Distributed load with electronic module for data acquisition and measured value display; position detected via Gray code reader |

|

|

Bars with electronic modules for data acquisition and measured value display; used to extend trusses in SE 200.01 |

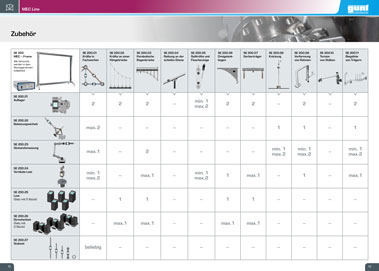

All experiments including required accessories at a glance

Experiment setup: easy & fast

The complete experiment can be set up quickly and easily. No tools are required. Both the mounting frame itself and the accessories are connected to each other using a click system.

The video on the right demonstrates an exemplary experiment setup on the subject of forces in trusses.

Examples of selected experiments

MEC - Cable forces and pulley blocks

Pulley blocks make it possible to lift heavy loads and are used, for example, with cranes.

- investigate 2 different pulley blocks at the same time

- 2 setup variants possible for each pulley block

- measurement of cable forces, support forces and displacement

- angular dependence of forces

- force measurement under different loads

Trusses are bar structures in which the bars are only subject to compressive or tensile stress, but not bending.

-

measurement of the bar

-

comparison of forces in statically determinate and statically indeterminate trusses

-

comparison of measurement results with mathematical solution methods: method of joints, Ritter’s method of sections, FEM

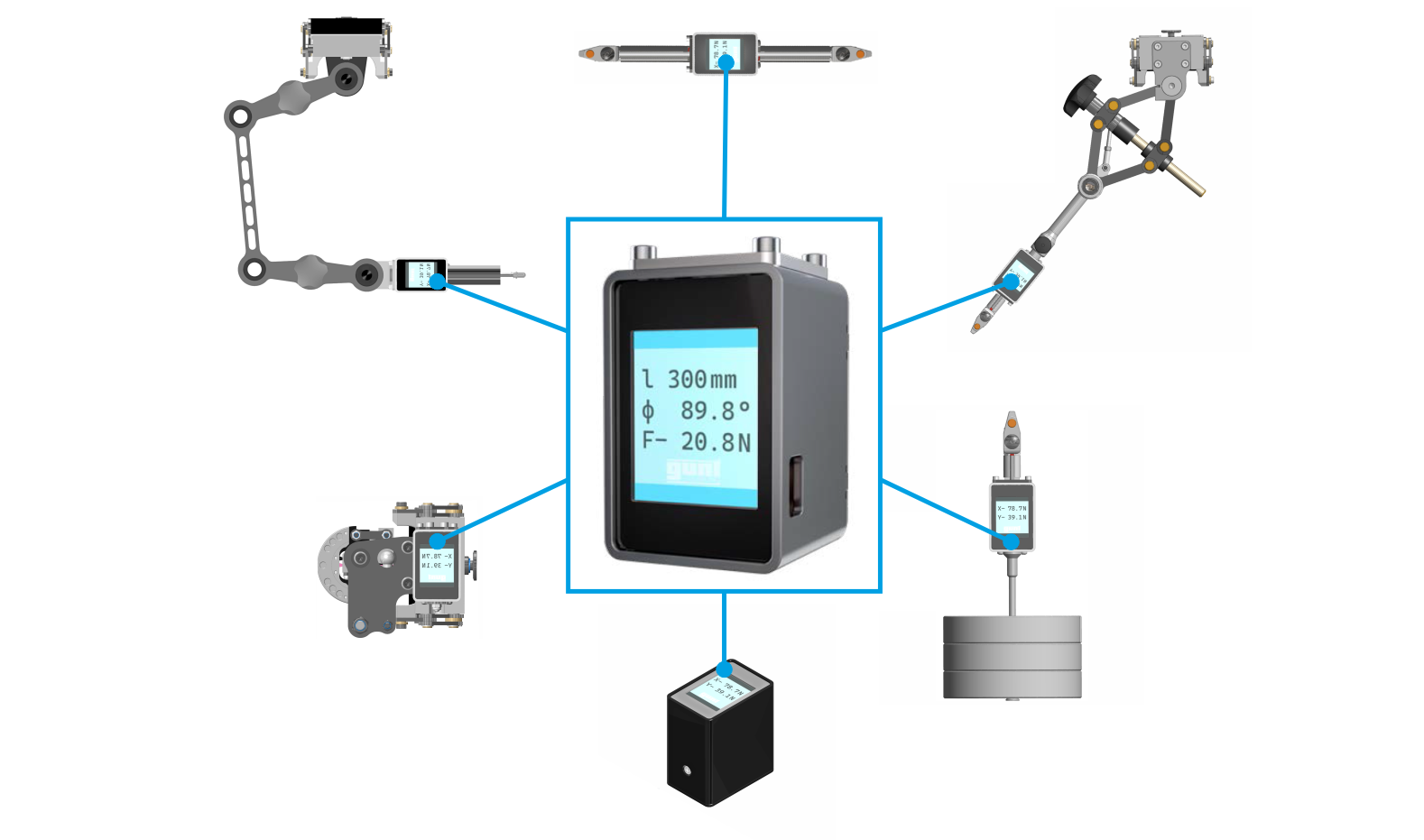

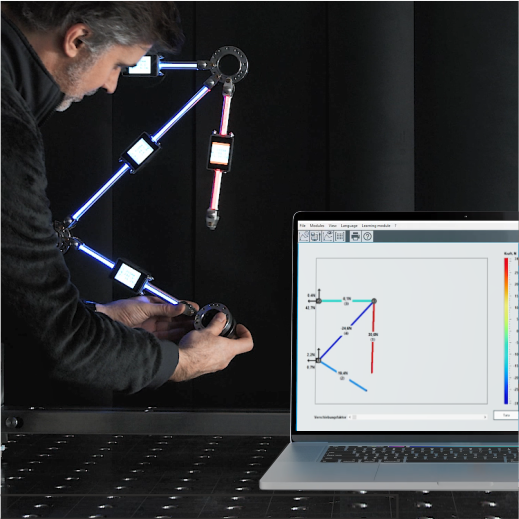

Smart components in detail

The use of modern measurement technology is indispensable in the structural monitoring of e.g. bridges. The competent handling of appropriate systems is essential for specialists. The MEC Line offers the opportunity to familiarise with basic digital structures.

All smart components of the MEC Line are equipped with an electronic module. The electronic module enables the direct display of measured values on a TFT display. An integrated acceleration sensor enables the automatic display alignment as well as the determination of the installation position. Different sensors allow the use for different measuring applications.

Force

- Planar beam load cells enable direct force measurement on bars, supports and loads. For this purpose, the load cell is directly adapted to the respective electronic module.

Angle

- Acceleration sensors in e.g. bars enable the precise angle measurement for the correct display of the geometry of the truss.

Path

- A linear potentiometer in the distance measurement is used, for example, to record the displacement in a truss. The articulated arm with a long reach offers a wide range of measurement options.

Position

- Gray code (reflected binary, RB) is used to determine the position of e.g. loads on a bridge. The Gray code reader integrated in the load detects the exact position using the code on the roadway.

- The GUNT topology algorithm allows the exact visualisation of the set up truss in the software. Already during setup, the bars are displayed in the correct position and angular position.

Software

The GUNT software is specifically adapted to each experiment. The experimental setups are partly transferred automatically to the software interface. The software reacts dynamically to changes. Measured values are automatically displayed in the software. In addition, an FEM calculation of the forces is carried out. The values can be optionally shown or hidden.

- measurement data acquisition and processing

- automatic identification of smart, communication-enabled components including position and orientation

- integration of FEM models

The software for SE 200.01 MEC - Forces in trusses offers the option of displaying the calculated displacement in an amplified form. For this purpose, the scaling is simply increased step by step via a button in the software. The otherwise hardly noticeable displacement thus becomes very clearly visible.

Digital media in the GUNT Science Media Center

The GUNT Science Media Center provides extensive multimedia teaching material for all experiments. Customers can access files and product information for selected products at any time and from any place. In addition to digital worksheets and the manual, access to E-Learning is also included.

Download

Order overview

In this overview you will find which products are needed for which experiments:

Accessories MEC Line

» Login Science Media Center

» Login Science Media Center