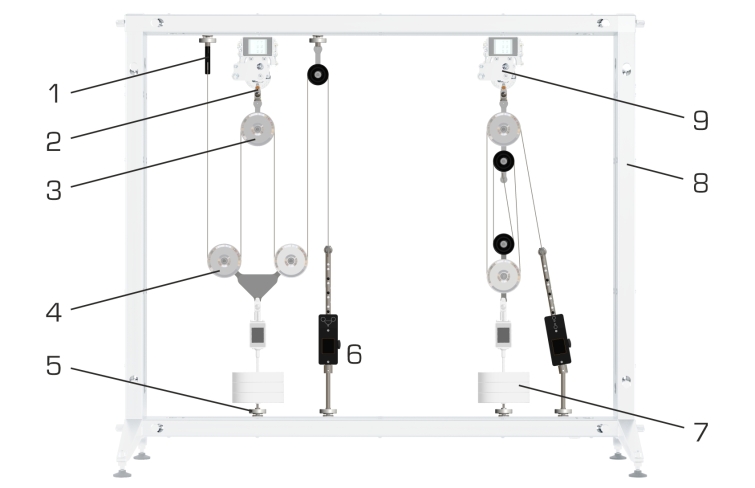

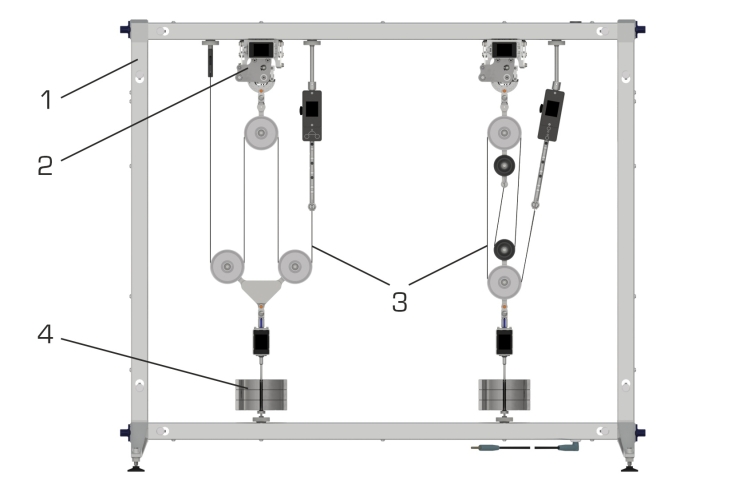

Pulley blocks make it possible to lift heavy loads and are used, for example, with cranes. SE 200.05, in combination with other accessories of the MEC Line, enables the smart, digitally supported experimental setup of pulley blocks. The experiment contains two pulley blocks of different designs with smart, communication-enabled suspension cables, equipped with electronic modules for data acquisition and measured value display. The experimental arrangement is set up in the SE 200 mounting frame. The stainless steel mounting frame provides direct and wireless data transmission and power supply for the smart components.

The pulley blocks have the same transmission ratio and can be investigated simultaneously. The transmission ratio is determined by the number of cable strands and pulleys used. It is possible to configure two setup variants with each pulley block. The force, angle and displacement measurement on the suspension cable has five snap-in points for setting different heights. The click system ensures the components easily snap into place.

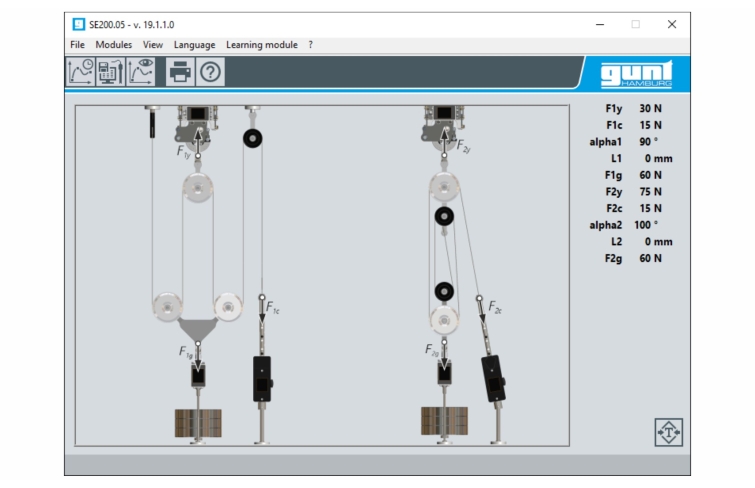

Accessories such as supports and vertical loads are available for the setup. Loading is applied to each of the pulley blocks by means of a vertical load on the lower pulley. In experiments, the forces, angles and displacement on the suspension cables are measured and displayed as a measured value both directly on the smart components and in the GUNT software. The GUNT software identifies and shows the position and location of the installed suspension cables as well as the support reactions. The lifting heights and the vertical loads used are also shown. The GUNT software reacts dynamically to changes. The visualisation in the software always corresponds to the actual pulley blocks fitted. The measured values are analysed in real time.

All components are clearly laid out and well protected in a storage system.