Heat transfer with the WL 110 series

Heat transfer with the WL 110 series

digital & practical

SMART features

|

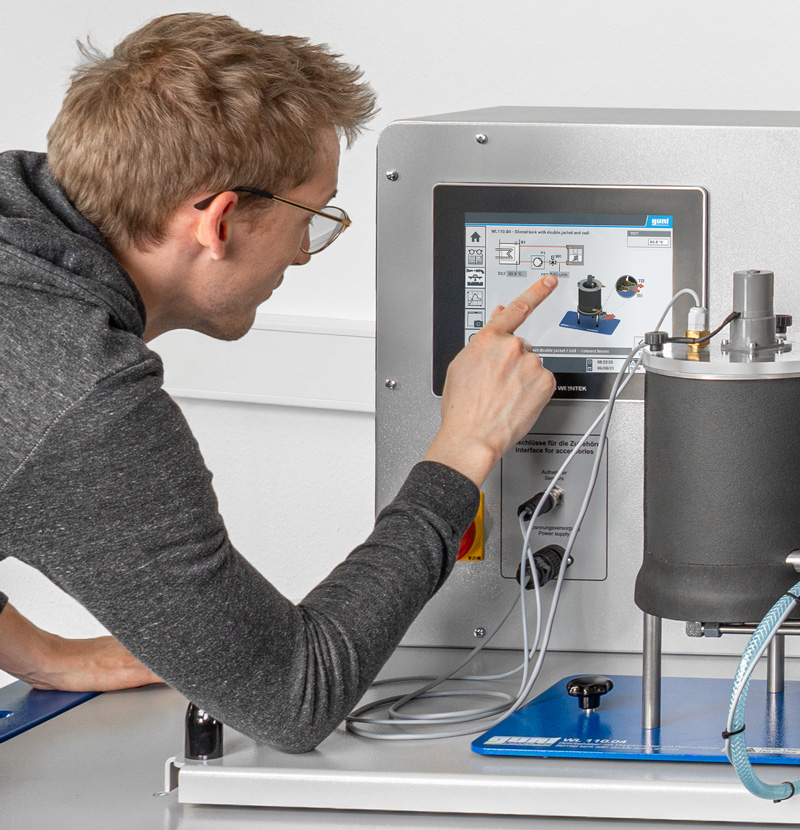

Intuitive operation and control via touch screen |

|

Screen mirroring, mirroring of the user interface on additional terminals |

|

RFID technology, automatic recognition of accessories |

|

» E‑Learning course, extensive multimedia teaching material |

Overview of the WL 110 series

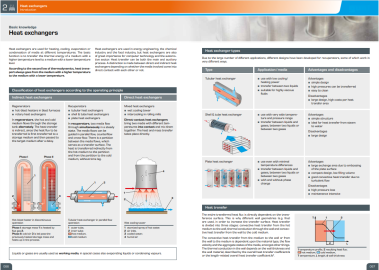

The WL 110 series provides a complete course for the investigation of different heat exchangers. The interaction between real experiments and digital teaching helps to methodically link and apply the learnt theory with real world, practical components.

Setup

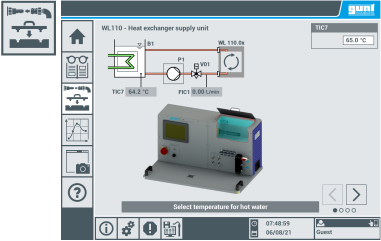

The WL 110 supply unit provides the basic supply for each of the individual experiments. The measurement, control and the communication systems are also provided by WL 110. Different types of heat exchangers are available as optional accessories. The supply unit identifies the respective accessory via RFID technology.

The cold water circuit can be fed from the laboratory mains or the WL 110.20.

Structure of the WL 110 series

WL 110 Heat exchanger supply unit

WL 110 serves as the supply and control unit for investigating different heat exchanger types. The supply unit provides the required cold and hot water circuits. The measurement, control and the communication systems are also provided by WL 110.

- plant control with PLC

- intuitive experiment execution via touch screen

- screen mirroring: possible to mirror the user interface on up to 10 end devices

- automatic identification of accessories via RFID technology

Heat exchangers as accessories

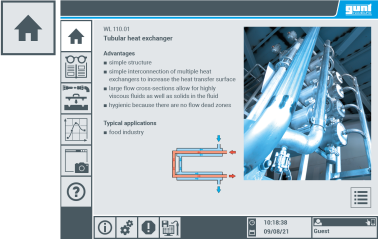

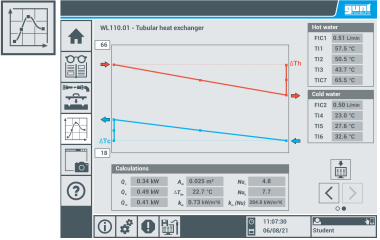

WL 110.01 Tubular heat exchanger

In the tubular heat exchanger, the hot water is fed through the core tube (inner) and the cold water fed through the jacket tube (outer).

- operation in

|

parallel flow | |

| counterflow |

- visible flow channel due to transparent outer tube

- two additional temperature sensors for measuring the central temperature

WL 110.02 Plate heat exchanger

The plate heat exchanger is made up of profiled plates with water flowing through the spaces between them. The plates are soldered in such a way that two separate flow channels are formed. These are one “cold” and one “hot” flow channel, in an alternating arrangement.

- operation in

|

parallel flow | |

|

counterflow |

- six soldered plates, stainless steel

WL 110.03 Shell & tube heat exchanger

The shell and tube heat exchanger consists of seven tubes, surrounded by a transparent outer shell. The hot water flows through the tube space and the cold water through the space in the shell.

- operation in

|

cross parallel flow | |

|

cross counterflow |

- transparent shell, visible tube bundle

- tube bundle consisting of 7 tubes and 4 baffle plates

WL 110.04 Stirred tank with double jacket and coil

The jacketed stirred tank is fitted with a coiled tube. In heating mode with jacket the hot water flows through the jacket. In heating mode with coiled tube the hot water flows through the coil. A stirring machine can be used in all modes.

- heating using

|

jacket | |

|

coiled tube |

- stirrer for a better mixing of the tank content and an even temperature distribution

- visible working area due to transparent cover

WL 110.05 Finned-tube heat exchanger

The WL 110.05 unit consists of a box section through which air flows and which is traversed several times by the pipe section carrying hot water. Fins are applied to the pipe section to increase the heat-transferring surface.

- heat transfer between water and air in cross-flow

- supply and exhaust air duct with transparent front wall for a clear view of the heat exchanger

- air flow generated by axial fan

Additional accessories

WL 110.20 Water chiller

- operation at high ambient and water temperatures

- setup of a closed cold water circuit

WP 300.09 Laboratory trolley

- comfortable setup and transport of experiments to another place

- three drawers for accessories

- three retractable sockets for power supply

Operation and data acquisition

For operation and control, the WL 110 series is equipped with a PLC and touch screen. By means of an integrated WLAN router, the experimental unit can additionally be operated and controlled via one end device and the user interface can be displayed on up to 10 end devices (screen mirroring).

The data acquisition is performed via the PLC on the internal memory. Stored measured values can also be transferred from the experimental unit to the end devices. Thus, experiments can be tracked and evaluated individually.

- plant control with PLC

- mirroring the user interface on additional end devices: PC, tablet,...

- independent menu navigation for all end devices

-

transfer of stored measured values to end devices

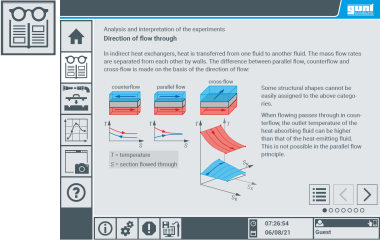

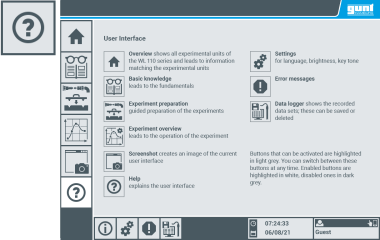

PLC software in detail

The PLC software content is adapted to the specific accessories. The user interface includes, for example, a guided experiment preparation, learning modules with theoretical basics as well as a graphical display of the measured values. The clear design with expressive symbols enables intuitive operation.

E-Learning course

A free E-Learning course on heat transfer enables independent learning of the theoretical fundamentals and follow-up of the experiments.

- multi-media online course, which enables learning independent of time and place

- check through targeted review of the learning objectives

-

all content is free of charge - you are welcome to use extracts for your lectures

Download

In our download area for the WL 110 series, you will find all documents available as PDF in one place.

You are also welcome to use extracts for your lessons.