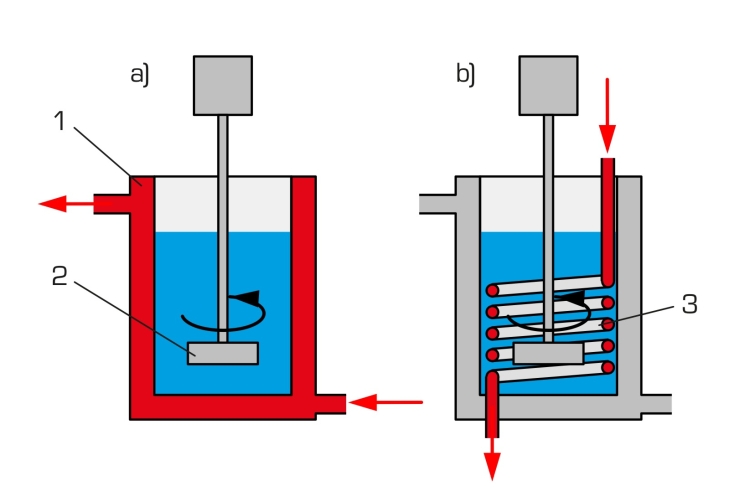

In many engineering processes, several basic operations are combined. For example, in a tank a chemical reaction takes place during which heat is to be supplied or removed. Such tanks are equipped with jacket or a coiled tube. Depending on the process, the medium in the jacket or in the coiled tubing is used for heating or cooling of the tank content. For a better mixing of the tank content and an even temperature distribution stirring maschines are used. The product temperature at an even temperature distribution is precisely adjustable. Considered here, the stirred tank with double jacket and coil is a model for such tanks.

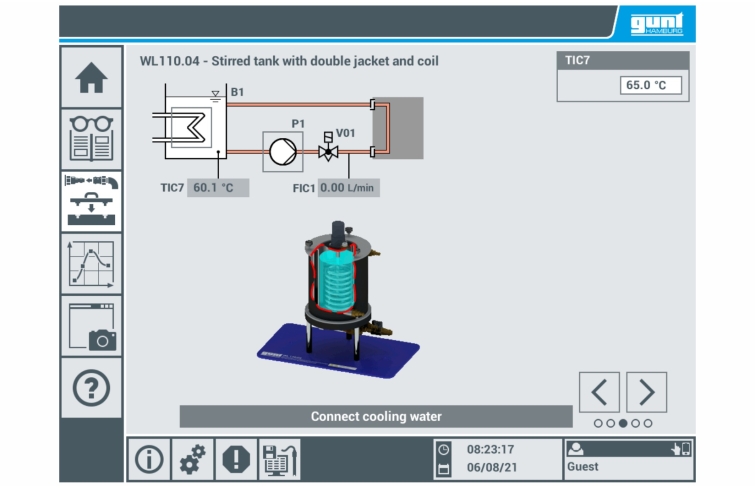

The jacketed stirred tank WL 110.04 is fitted with a coiled tube. In “heating mode with jacket” the hot water flows through the jacket and transfers a part of the thermal energy to the cold water in the tank. In “heating mode with coiled tube” the hot water flows through the coil and heats the cold water in the tank. A stirring machine can be used in all modes. During experiments, time functions are plotted and displayed graphically.

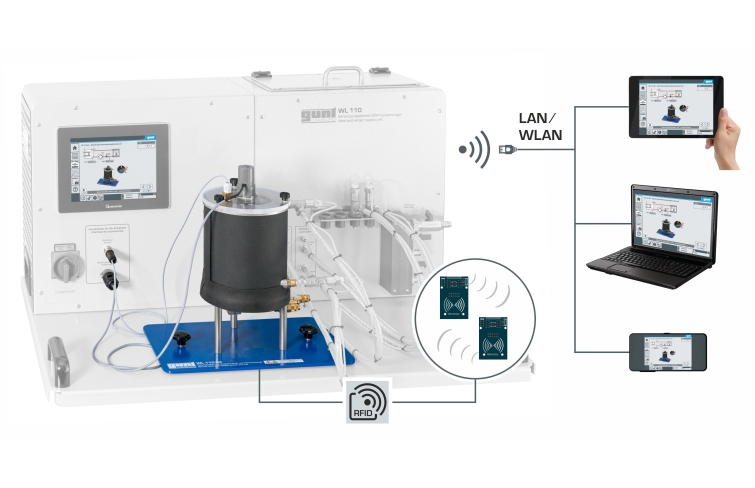

The accessory WL 110.04 is easily and safely positioned on the worktop of the WL 110 supply unit. Via RFID technology the accessories are automatically identified, the appropriate PLC software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection.

Temperature sensors for measuring the inlet and outlet temperatures are located at the supply connections of the WL 110. An additional temperature sensor measures the temperature in the stirred tank. The supply of hot and cold water, the settings for flow and speed as well as the measurement of inlet and outlet temperatures are carried out via the supply unit.