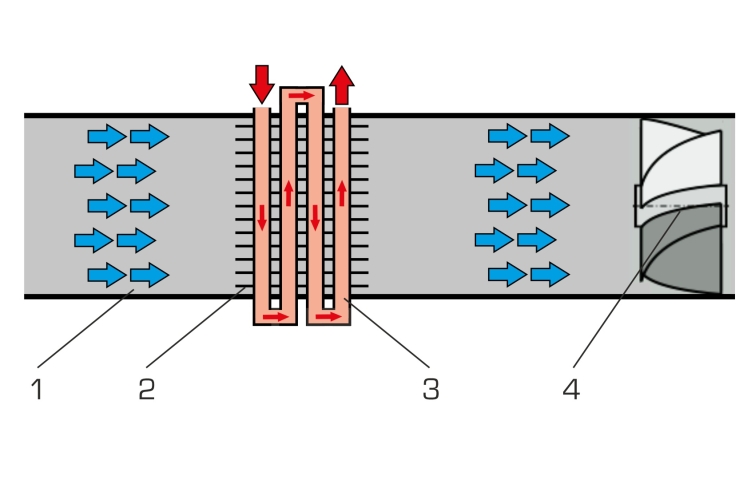

The heat transfer surface of a heat exchanger can be effectively increased by attaching fins. This principle is used in the finned tube heat exchanger primarily to cool or heat a closed circuit using the ambient air. One typical application example is the air cooler for combustion engines.

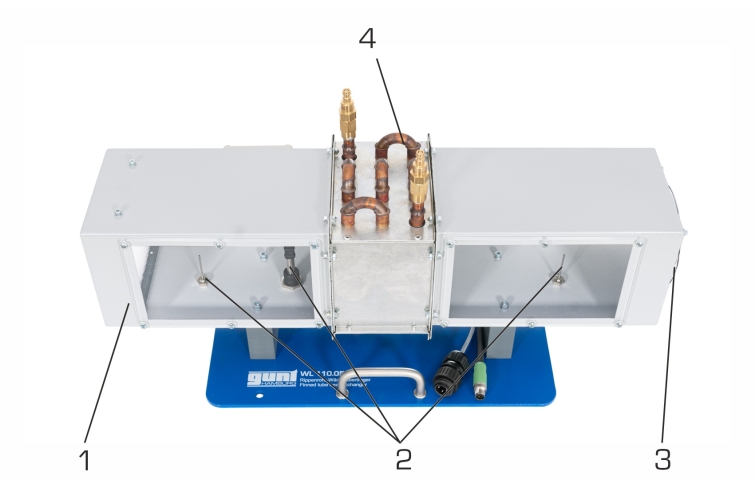

The WL 110.05 consists of a box shaped profile through which air flows and which is traversed several times by the pipe section carrying hot water. This creates a cross-flow of the heat-transferring media. The hot water emits part of its thermal energy to the air. Fins are applied to the pipe section to increase the heat-transferring surface.

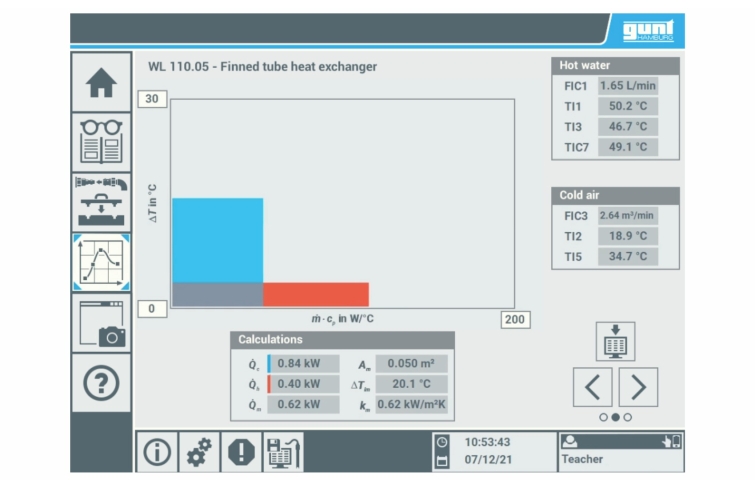

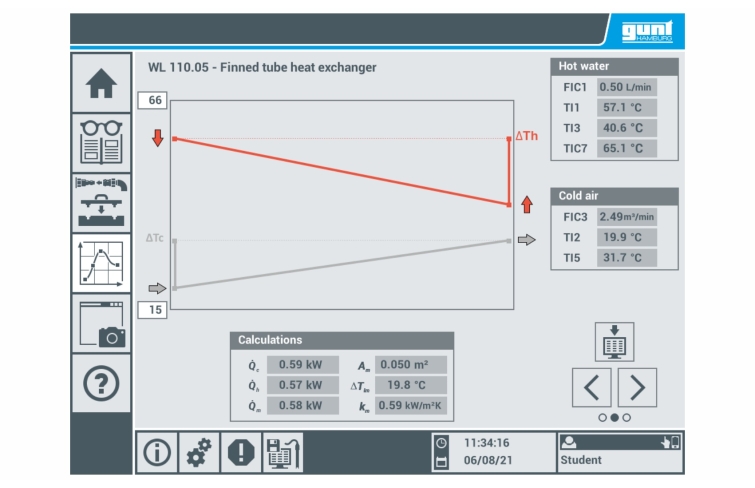

Temperature curves are plotted in experiments and displayed graphically.

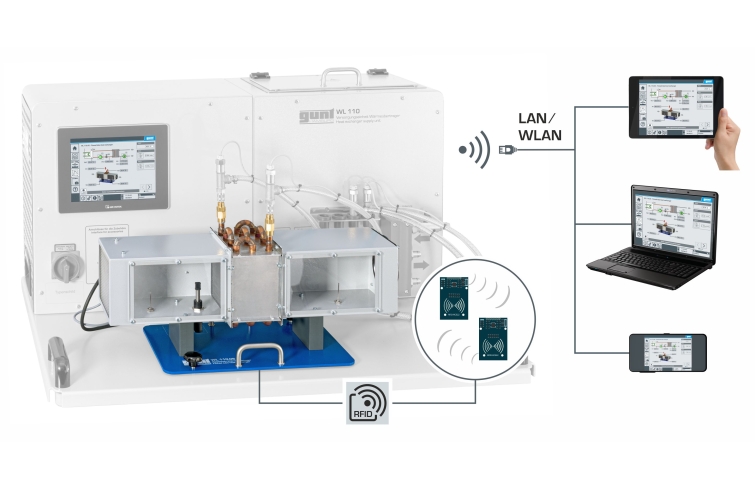

The accessory WL 110.05 is positioned easily and securely on the work surface of the WL 110 supply unit. The accessories are identified automatically using RFID technology. The appropriate GUNT software is then loaded and the system is configured automatically. The intuitive user interface guides you through the experiments and displays the measured values graphically. Up to ten external workstations can be used simultaneously to follow and analyse the experiments via the local network using a LAN connection.

Temperature sensors for measuring the inlet and outlet temperature are located at the supply connections of WL 110. Two additional temperature sensors measure the air temperature. The flow velocity of the air is also recorded. The hot water is supplied via the supply unit, which is also used to configure the settings for the flow rate of water and air and for the measurement of inlet and outlet temperatures.