Find out more about us! A look behind the scenes ... GUNT story, GUNT production, GUNT knowledge

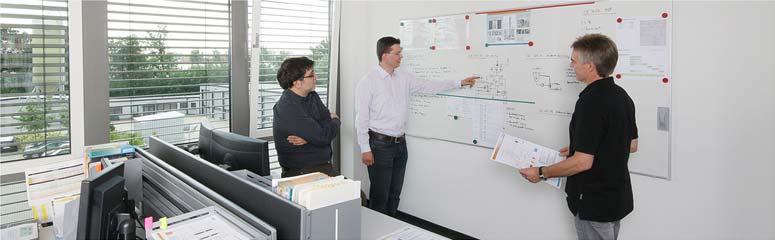

Development and construction

Starting from an idea, a team of GUNT designers develops a complete didactic concept, partly in cooperation with universities. If necessary, GUNT software and the learning software are part of the development.

In order to complete the overall concept, the instructional material contains the instruction manual, basic knowledge on the learning objectives and comprehensive experiment instructions.

Fabrication and assembly

The developed device is produced in the GUNT fabrication and assembly.

The manufacturing machines at GUNT are state-of-the-art of best available technology. A total of 70 skilled workers and technicians are responsible for the professional production of the equipment. In order to ensure the required quality characteristics of the GUNT devices, the production process is precisely defined and runs through a sequence determined for each device.

Commissioning and quality control

Before the assembled devices leave GUNT, each device is checked carefully: from leak tests to functional tests with experiments, to checking safety. Not until all tests have been successfully passed and documented the unit can be packed and delivered.

Packaging and transmission

GUNT sells and sends products all over the world. In order to ensure the correct packaging for a safe transport and an undamaged arrival of the products, GUNT has its own department for the making of packaging. All devices with their different dimensions are custom packaged and carefully prepared for transportation before they go on their journey. This ensures that customers receive their ordered products safely and undamaged.

On-site commissioning / training

Upon arrival of the delivery at the customer, the devices are usually installed and commissioned by the GUNT service staff. A briefing to become acquainted with the devices takes place on site. If necessary, the laboratory staff can be trained on the equipment in detail.