Heat exchangers transfer thermal energy from the flow of one medium to another. The two flows do not come into direct contact with one another. Efficient heat transfer is a prerequisite for economical processes. Therefore, different heat exchanger types are used in practice depending on the requirements.

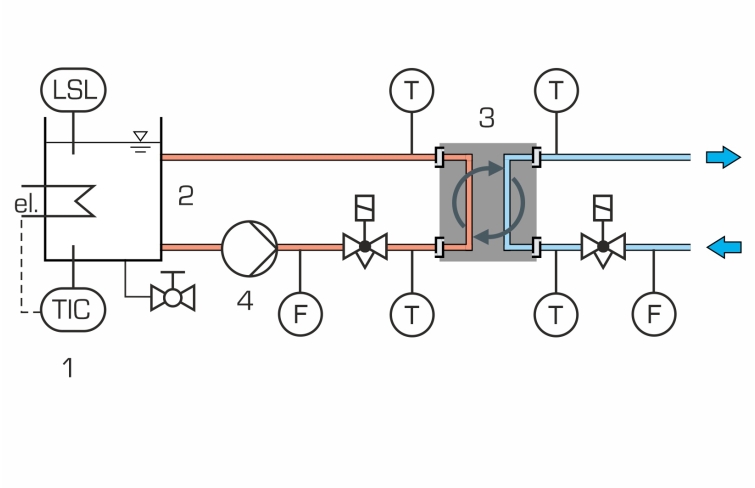

The main function of the WL 110 is to provide the required cold and hot water circuits. To do this, the supply unit is equipped with a heated tank and pump for the hot water circuit as well as connections for the cold water circuit. The cold water circuit can be fed from the laboratory mains or the water chiller WL 110.20.

The measurement, control and the communication systems are provided by WL 110.

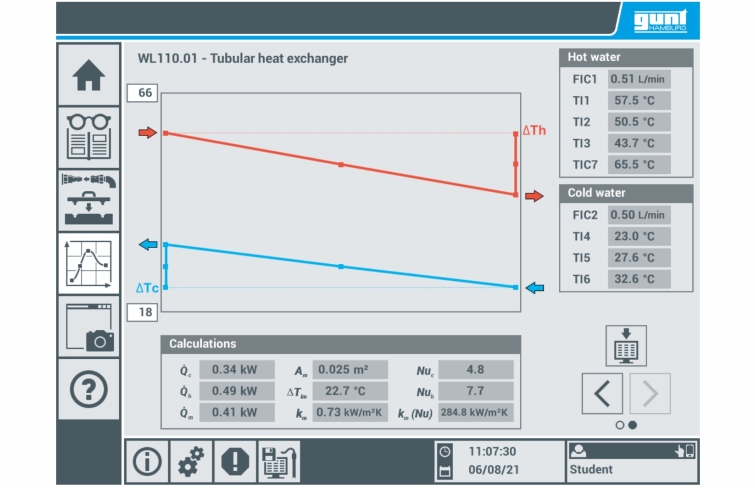

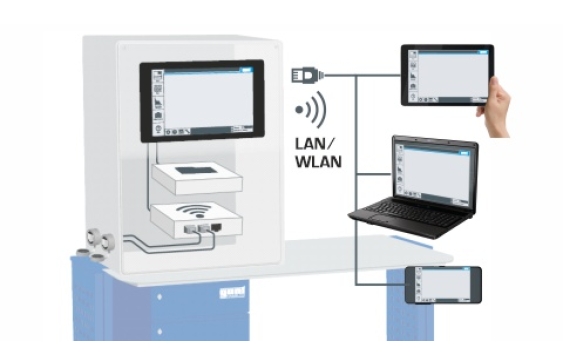

Different types of heat exchangers are available as optional accessories. The accessories are simply and safely positioned on the worktop of WL 110. After positioning, the supply unit identifies the respective accessory via RFID technology, automatically selects the appropriate software in the PLC and performs an automatic system configuration. The unit is operated via a touch screen. By means of an integrated router, the experimental unit can also be operated and controlled via end device. The user interface can be displayed on up to 10 end devices (screen mirroring). The user interface includes a guided experiment setup, learning modules with theoretical basics and a graphical representation of the measured values.

For tracking the experiments, up to 10 external workstations can be used simultaneously via the local network using a LAN connection. Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/ LAN connection to the customer’s own network.