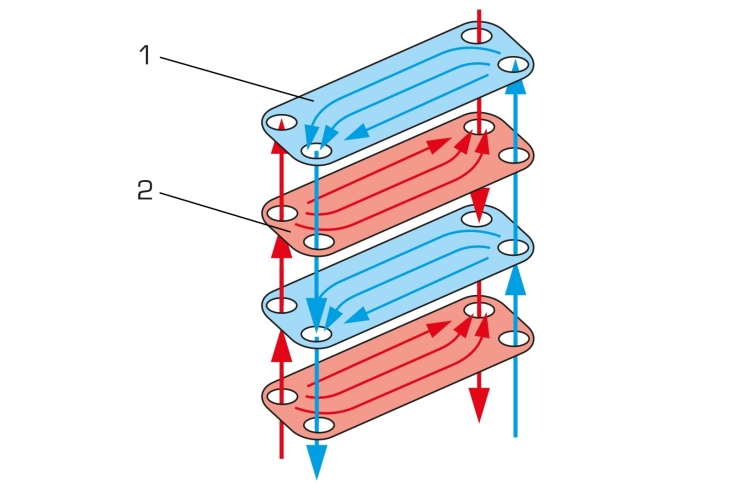

The key feature of plate heat exchangers is their compact design, in which optimum use is made of all of the material for heat transfer. The pressed in profile on the plates creates narrow flow channels, in which significant turbulence occurs. The turbulent flow allows effective heat transfer even with low flow rates and also has a self-cleaning effect. Plate heat exchangers are used in the food industry, offshore technology, refrigeration and domestic engineering.

The plate heat exchanger WL 110.02 is made up of profiled plates with water flowing through the spaces between them. These are one “cold” and one “hot” flow channel, in an alternating arrangement. Part of the thermal energy of the hot water is transferred to the cold water. The supply hose can be reconnected using quick-release couplings, allowing the flow direction to be reversed. This allows parallel flow or counterflow operation.

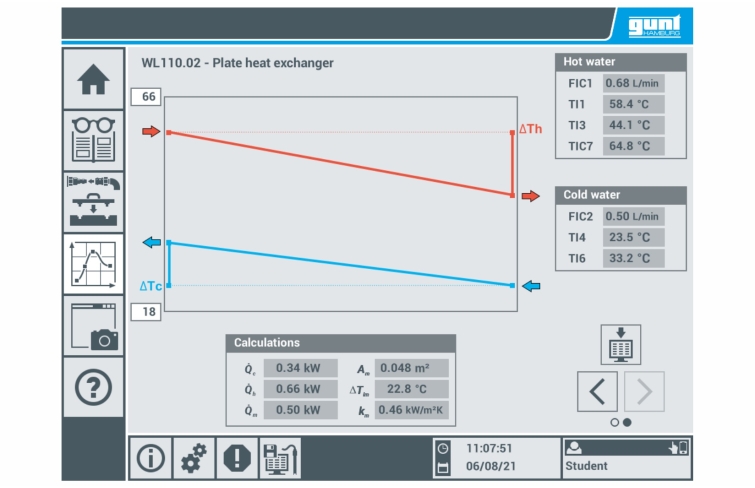

During experiments, temperature curves are plotted and displayed graphically. The mean heat transfer coefficient is then calculated as a characteristic variable.

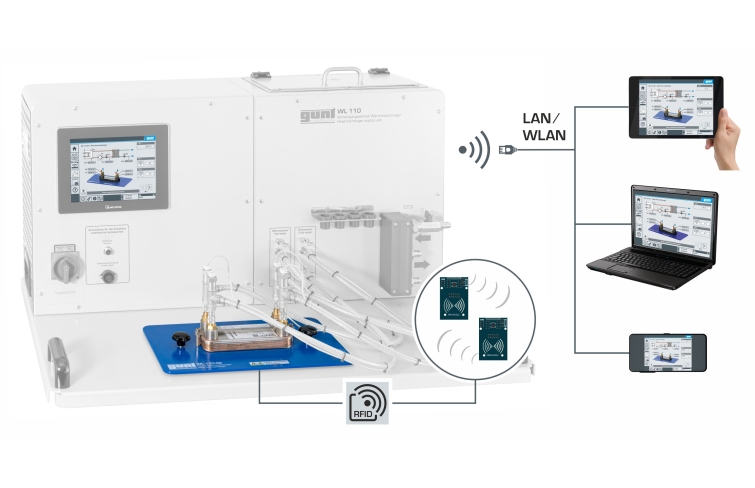

The accessory WL 110.02 is easily and safely positioned on the worktop of the WL 110 supply unit. Via RFID technology the accessories are automatically identified, the appropriate PLC software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection.

Temperature sensors for measuring the inlet and outlet temperatures are located at the supply connections of the WL 110. The supply of hot and cold water, the flow setting and the measurement of inlet and outlet temperatures are carried out via the supply unit.