Suspension bridges consist of sagging suspension cables to which a walkway or roadway is attached. They are used to span long distances.

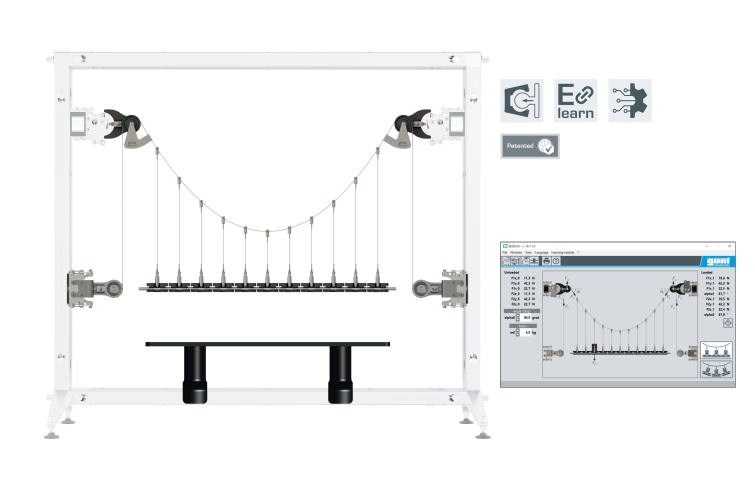

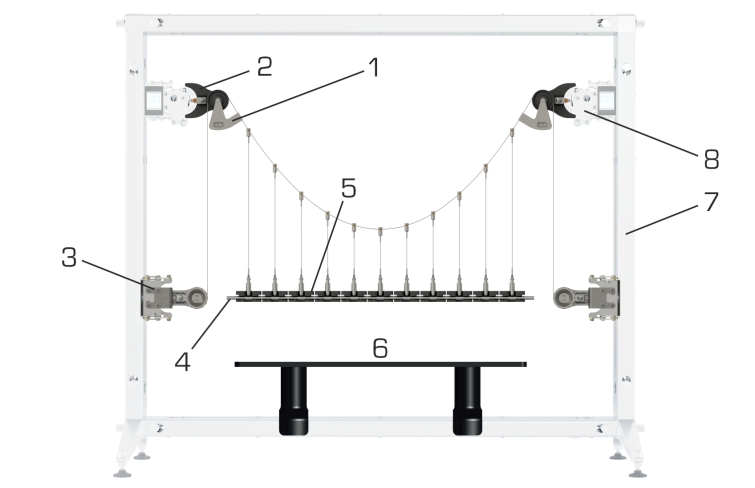

SE 200.02, in combination with other accessories of the MEC Line, enables the smart, digitally supported experimental setup of a suspension bridge. The experiment includes a suspension bridge with hangers and a horizontal roadway. Supports and loads are available as smart accessories. The experimental arrangement is set up in the SE 200 mounting frame. The stainless steel mounting frame provides direct and wireless data transmission and power supply for the smart components. The click system ensures the components easily snap into place.

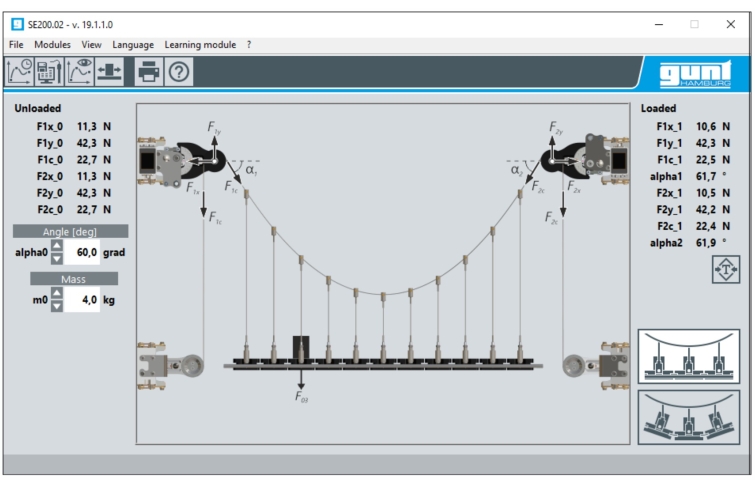

A load can be placed at each of eleven positions on the roadway. By combining several load elements, it is possible to generate distributed loads or the prefabricated distributed load can be used. It is also possible to investigate a moving load.

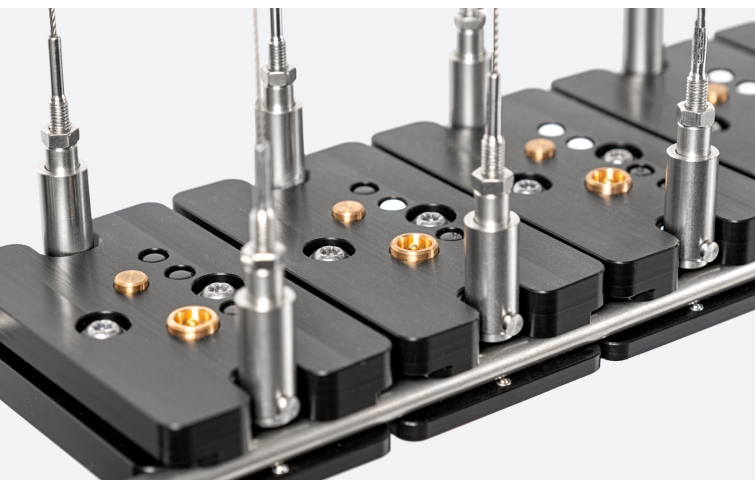

The roadway is flexible and can assume a rigid behaviour by using rods. In experiments, the forces on the supports and the loads are measured and displayed as a measured value both directly on the smart components and in the GUNT software. The exact position of the loads on the roadway is recorded using a binary code (Gray code). The GUNT software identifies the position and location of the applied loads and reacts dynamically to changes. The angle of application of the forces is displayed directly on the suspension cable. The suspension cable forces on the supports are calculated and also displayed in the GUNT software. The measured values are analysed in real time.

A support for the bridge as a setup aid and when taring the weights makes the unit easier to handle. All components are clearly laid out and well protected in a storage system.