This experimental unit provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of level control.

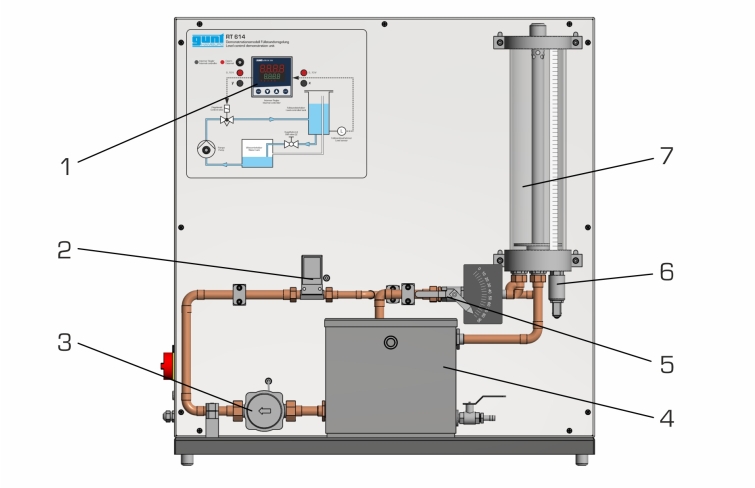

All components are clearly laid out on a vertical panel. The large-format process schematic provides an aid to understanding.

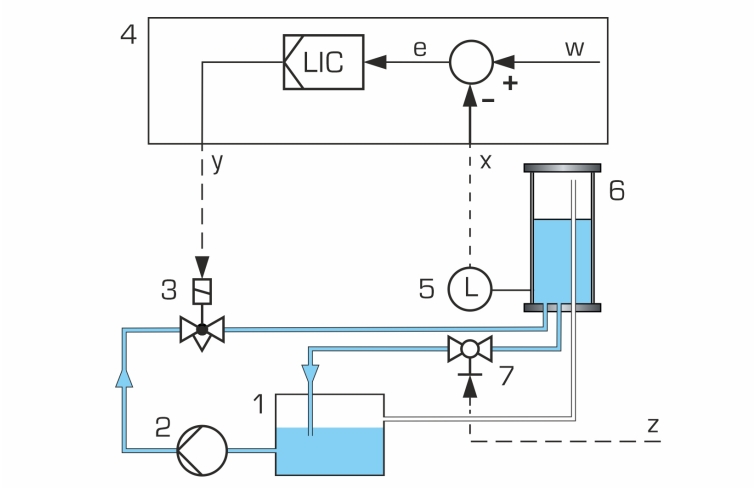

The controlled system represents a transparent tank. This is fed with water from a storage tank via a pump. The measuring element is a pressure sensor installed at the base of the transparent tank, which detects the level as the controlled variable. The controller used is a state-of-the-art digital industrial controller. An electropneumatic proportional valve is installed in the feed line to the tank as an actuator in the control loop. A ball valve in the outlet enables defined disturbance variables to be generated. The controlled variable X and the manipulating variable Y can be tapped as analogue signals at lab jacks. This enables external recording equipment, such as a plotter or an oscilloscope, to be connected.

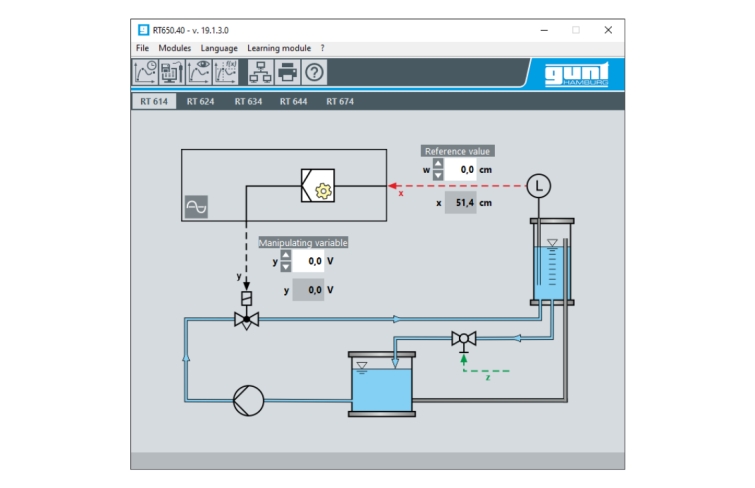

An instrumentation and control software (RT 650.40) with interface module (USB) is available as an accessory. This enables the key process variables to be represented, and control functions executed.