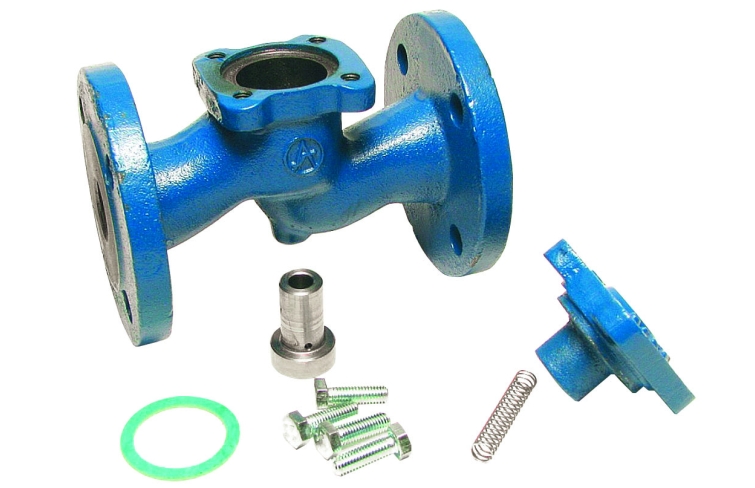

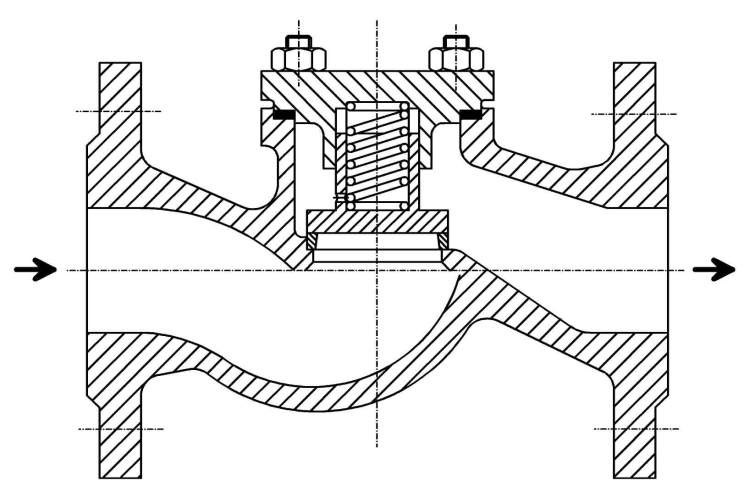

Non-return valves are used where flow reversal is not permitted. They must fully seal off the reverse direction while offering the lowest possible resistance in the forward flow direction. If the differential pressure of the medium falls below the value as dictated by the spring force, the valve closes. Non-return valves are installed in pipelines, and must close if the pressure drops or if a high back-pressure occurs. They are largely maintenance-free and low-wearing.

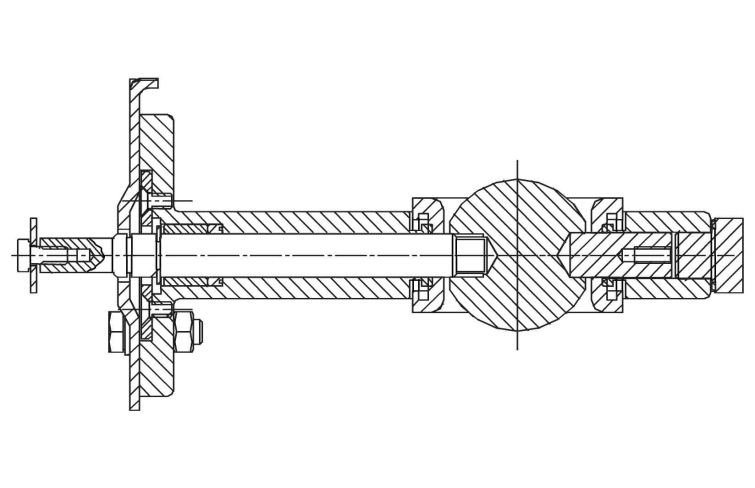

Butterfly valves are installed in the pipelines of water supply pumping stations and filter systems; in power plant cooling circuits; in the chemical industry for process water, including acidic and alkaline media; and in sewage treatment plants. They seal drip-tight like gate valves, and take up little space, as they are usually similar in size to the pipe cross-section.

Butterfly valves are constructed for ultra-large nominal widths (DN5300). Their operating pressure is normally in the range 4…16bar. Butterfly valves may be operated by hand, by electric motor via a spur gear segment or worm gear, or by a hydraulic piston. The valve is closed by rotating its shaft through 90°.

The MT 157 practice kit forms part of the GUNT Practice Line for assembly, maintenance and repair designed for training at technical colleges and in company training centres. A close link between theory and practice is key to the learning content.

MT 157 enables two typical industrially relevant valves and fittings to be assembled and disassembled. Students become familiar with all the components and their modes of operation. The parts are clearly laid out and well protected in a tool box. Systematic assembly and disassembly of the valves and fittings is practiced. The accompanying material details the individual steps involved in assembly, and provides additional information on the areas of application, mode of operation and design of the valves and fittings.