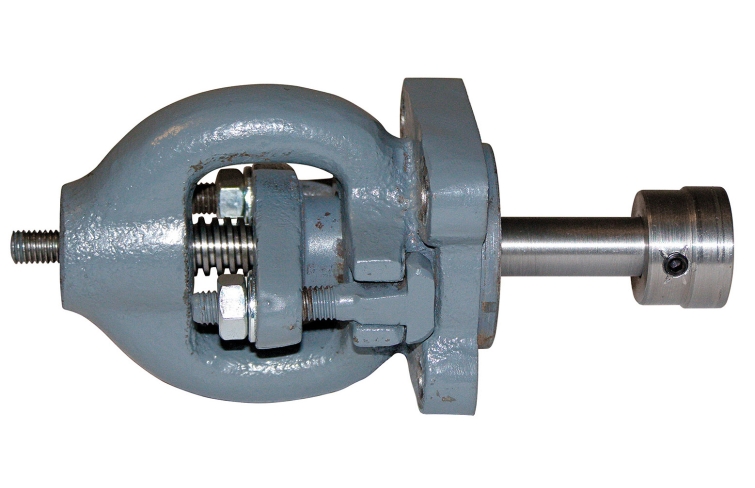

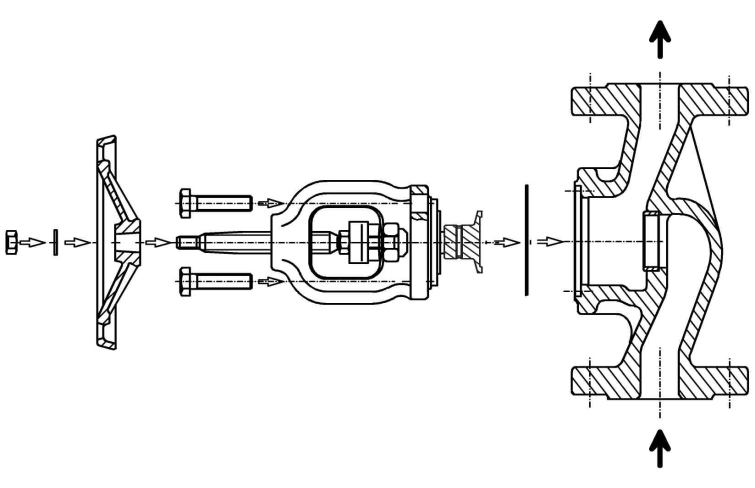

Shut-off valves, of the design presented here, are used to shut off and restrict the flow of media. They must be capable of complete flow shut-off. Closure of the valve should be such that the volumetric flow does not suddenly drop to zero in order to prevent shock loads. The valve taper is moved by the spindle and makes a metallic seal against the seating ring pressed into the housing. The spindle is sealed by a packing gland. The joint between the housing and the clamp cover is sealed by a flat seal.

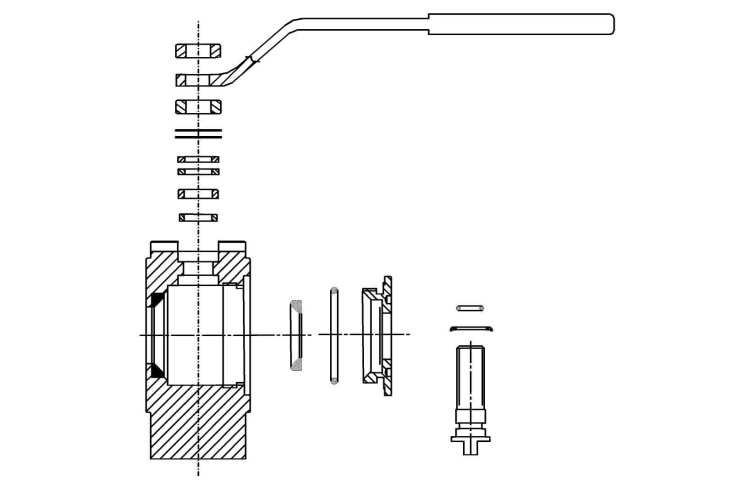

Ball valves are used where media flows or pressures in pipelines need to be stopped quickly and easily, e.g. when valves and fittings are to be removed from a pressurised pipeline. They have a very low flow resistance when open, require little space due to the compact design, and have a self-cleaning sealing face. The sealing body is a ball with a cylindrical bore allowing full flow when the valve is fully open. The ball is rotated through 90° by way of a lever with spindle, enabling it to open or close the valve fully.

The MT 158 practice kit forms part of the GUNT Practice Line for assembly, maintenance and repair designed for training at technical colleges and in company training centres. A close link between theory and practice is key to the learning content.

MT 158 enables two typical shut-off valves to be assembled and disassembled. Students become familiar with all the components and their modes of operation. The parts are clearly laid out and well protected in a tool box. Systematic assembly and disassembly of valves and fittings is practiced. The accompanying material details the individual steps involved, and provides additional information on the areas of application, mode of operation and design of the fittings.