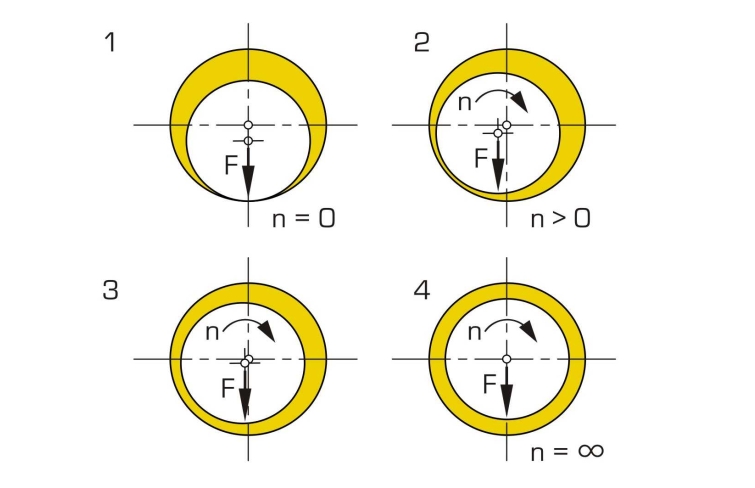

Journal bearings generally execute a sliding motion between a bearing journal and a bearing shell. This sliding motion is usually lubricated by an intermediate medium. Hydrodynamic journal bearings give wear-free continuous duty for large diameters at high speeds, and are suitable for high and shock-type loading. They are usually constructed as split bearings. Frictional heat occurring during operation must be dissipated by the lubricant.

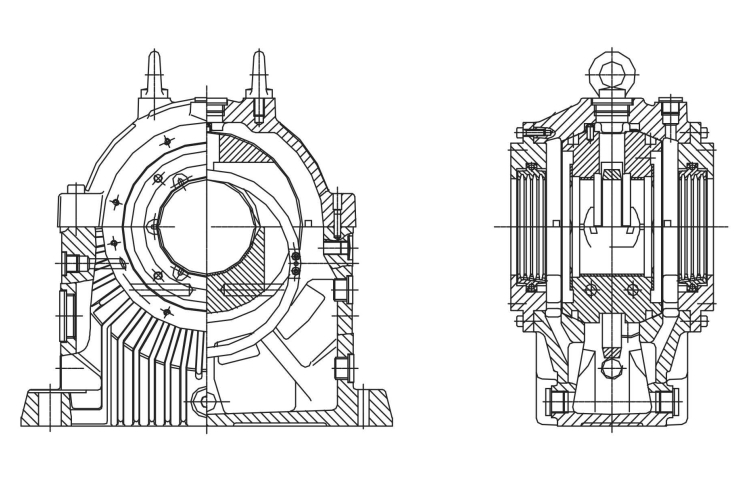

MT 171 is a horizontally split hydrodynamic pedestal journal bearing. The bearing shells are supported by a spherical face in the bearing housing so as to ensure uniform transfer of any forces that arise on the bottom part of the housing. The journal bearing is lubricated by a loose lubricating ring. Standard commercially available mineral oils can be used. An auxiliary shaft is supplied together with the bearing as an aid to assembly and functional testing.

The MT 171 kit is part of the GUNT Practice Line for assembly, maintenance and repair, which has been designed for technical colleges and company training centres. The close link between theory and practice-based learning content is evident. MT 171 enables a hydrodynamic journal bearing to be assembled and disassembled. Students become familiar with all the components and how they work.

The individual parts are laid out clearly and are well protected in a tool box. The accompanying material details the individual steps involved in assembly, and provides additional information on the areas of application, mode of operation and design of the journal bearing.