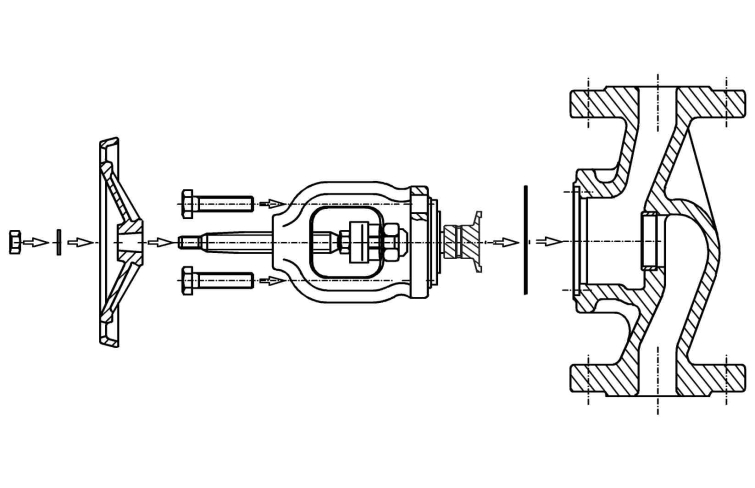

Shut-off valves of the type included in the MT 154 unit are used to shut-off and restrict the flow of media. They must be capable of total flow shut-off. The closing of the valve should be such that the volumetric flow does not suddenly drop to zero so as to prevent shock loads. The valve taper is moved by the spindle and ensures a metallic seal against the seating ring pressed into the housing. The spindle is sealed by a packing gland. The joint between the housing and the clamp cover is sealed by a flat seal.

The MT 154 project unit presents an introduction exercise to the area of assembly techniques. The assembly and disassembly processes can easily be completed within standard lesson times. Basic tools, all supplied with the kit, are required for assembly.

The unit is of most benefit in teaching if small groups of two to three students work independently. The group has a defined task to perform, with clear assignments to complete.

The comprehensive instructional material is oriented to practical needs. It includes a complete set of drawings with an overview drawing, parts list and single-part drawings.

Together with the valves and fittings test stand MT 162, the assembled valve can be subjected to a pressure test.