The CE 630 allows a soluble component of a solid mixture to be extracted with a revolving extractor.

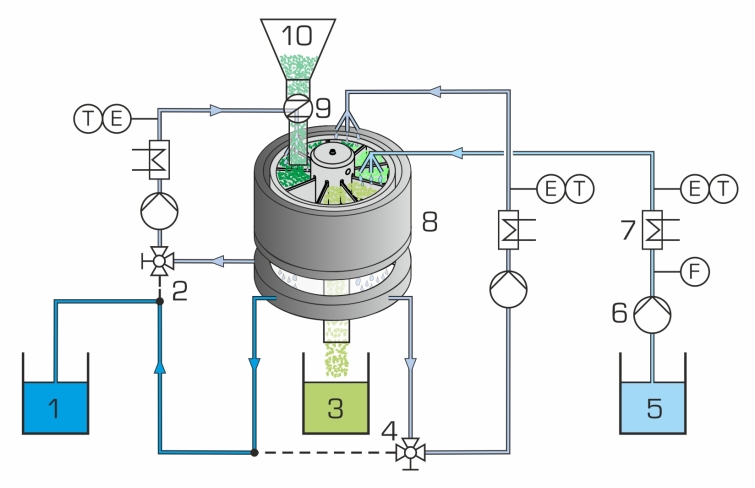

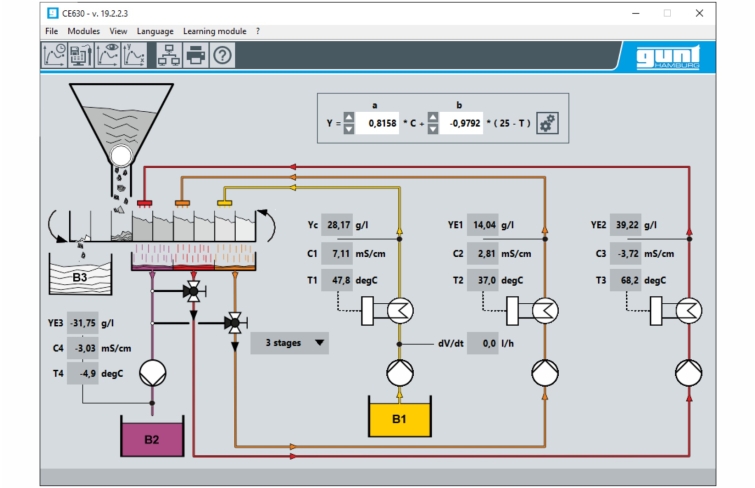

In continuous 3-stage mode, pure solvent (distilled water) is delivered from a tank to the sprinkler of the first extraction stage where it is distributed over the solid mixture (extraction material). The solvent seeps through the extraction material, absorbs its soluble components (potassium hydrogen carbonate) and passes into the collecting segments. From there, the enriched solvent is delivered to the sprinkler of the next stage. After passing through the last stage, the extract (the solvent charged with the extracted component) is collected in the extract tank. The extraction material is continuously fed into the cells of the rotating extractor by a spiral conveyor. The extraction material and the solvent move in counterflow. The extraction residue drops into a tank after one revolution of the extractor.

Valves can be used to switch to 1-, 2- or 3-stage continuous mode. Discontinuous mode is possible with the extractor stopped.

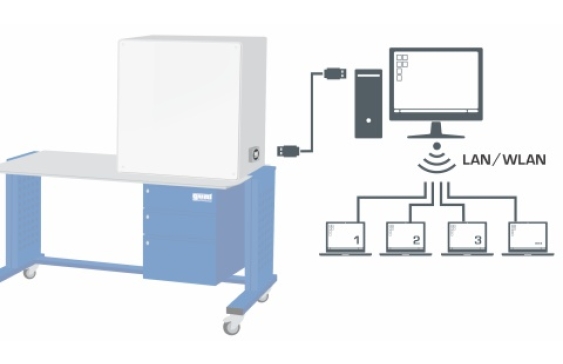

Three pumps are available for delivering the solvent. Their speed can be individually adjusted for each stage. The temperature of the solvent can likewise be adjusted for each stage with PID controllers. Each stage is equipped with conductivity sensors to monitor the separation process. All measured values can be viewed by software.

The solid mixture (extraction material) is produced prior to the extraction experiment. The carrier material (granular aluminium oxide) is fed into a salt solution (potassium hydrogen carbonate dissolved in water). The carrier material soaked with the salt solution is then dried.