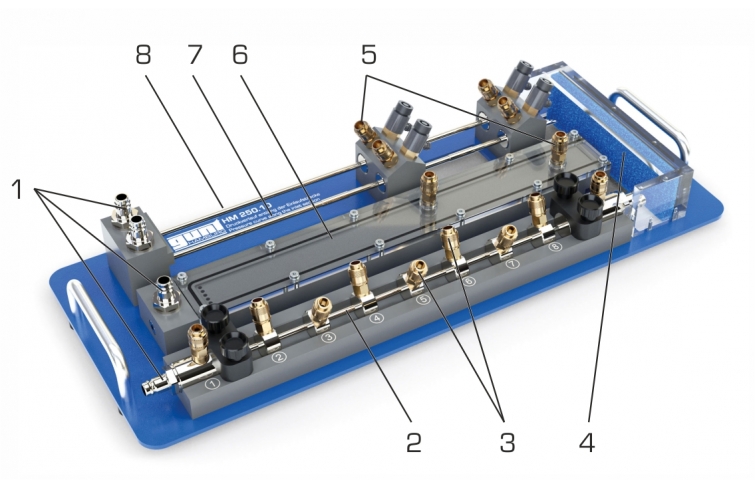

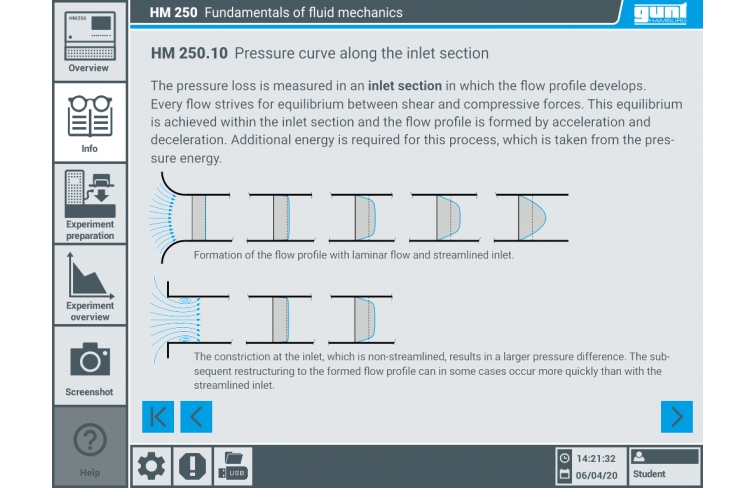

In pipe flow, the surfaces, the cross-sectional geometries and the geometry of the inlet section influence the internal friction and thus also the flow formation. In HM 250.10 the flow processes in the pipe inlet and in the formed flow are investigated. For this purpose, the experimental unit contains three pipe sections for the general investigation of the pipe flow and one pipe section which serves as a pure inlet section.

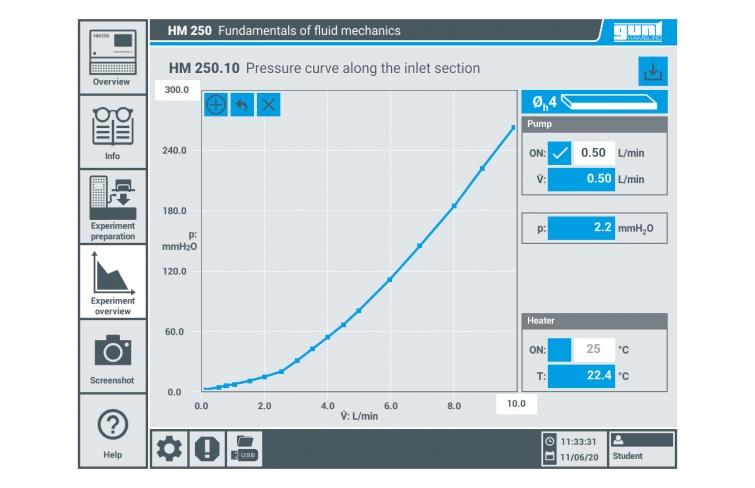

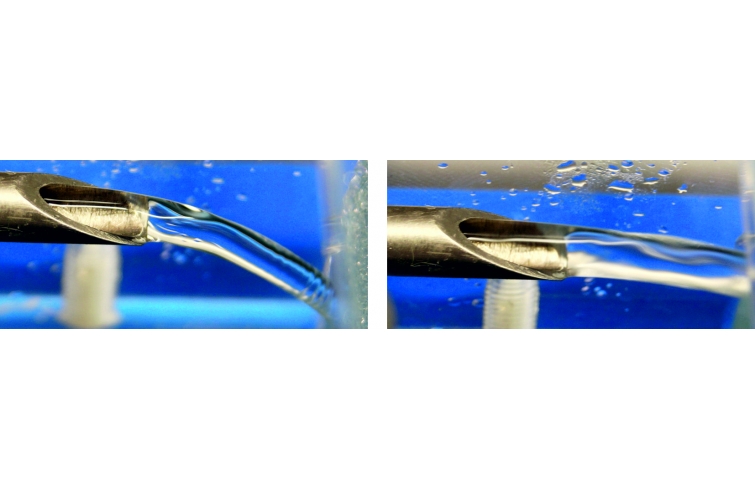

In experiments, the three pipe sections with different pipe surfaces and geometries are examined. The two key figures Reynolds number and pipe friction coefficient are determined from the measured values and can be displayed in the Moody diagram. The pressure is measured individually for each pipe section in the formed flow area. The water emerges from the pipe section as a free jet. Differences in the flow formation can be observed on the surface of the water jet.

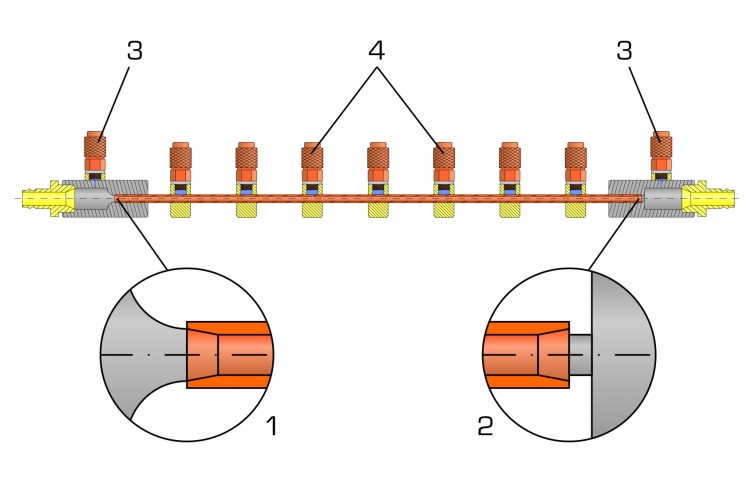

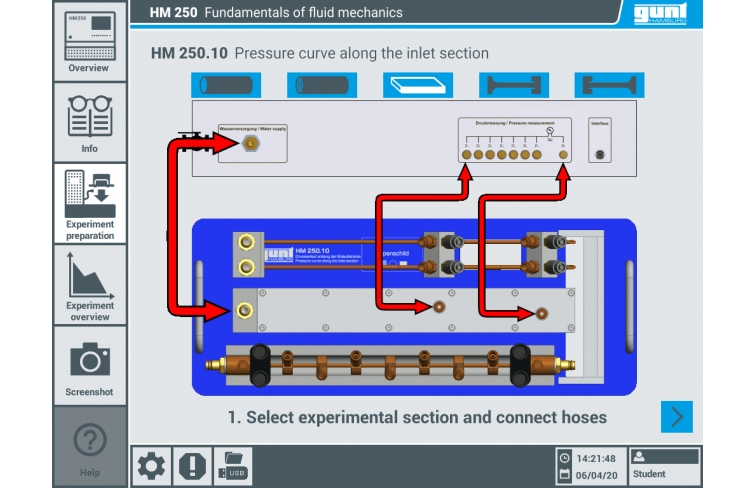

The inlet section has a streamlined and a non-streamlined inlet. The inlet section can be turned in the experimental unit. In this way different geometries can be investigated at the pipe inlet. The inlet section has pressure connections for measuring the pressure loss at the pipe inlet and along the inlet section.

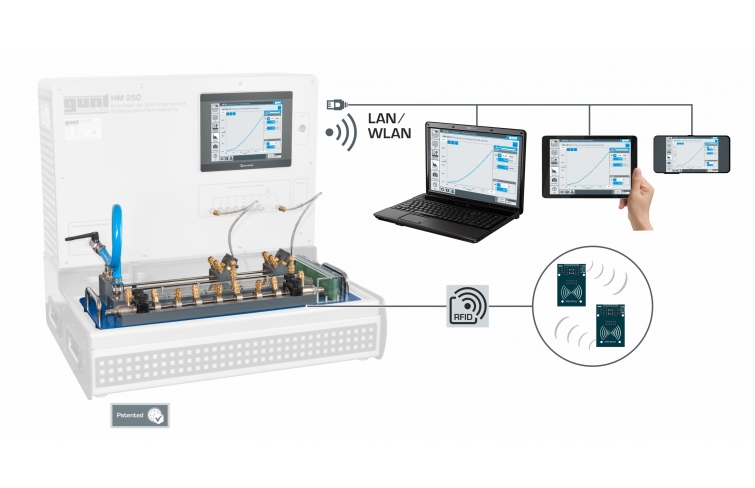

The accessory HM 250.09 is positioned easily and securely on the worktop of the HM 250 base module. Via RFID technology the accessories are automatically identified, the appropriate GUNT software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments and displays the measured values graphically. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection. The base module supplies the water and is used to adjust the flow rate and temperature. Flow rate, pressure and temperature measurements are also carried out via HM 250.