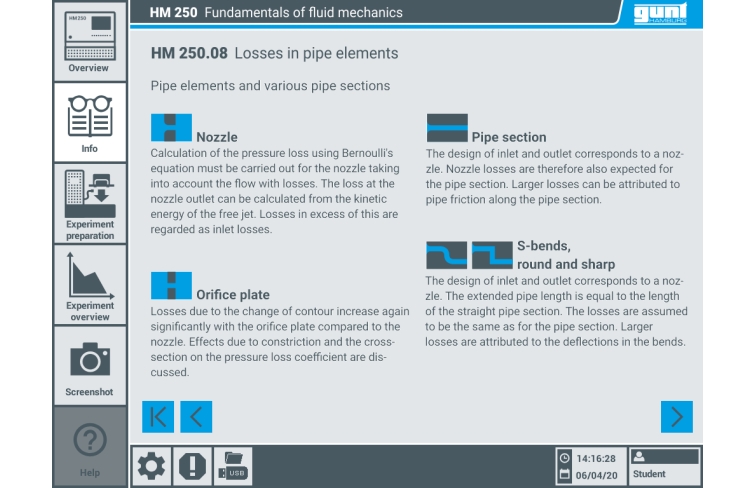

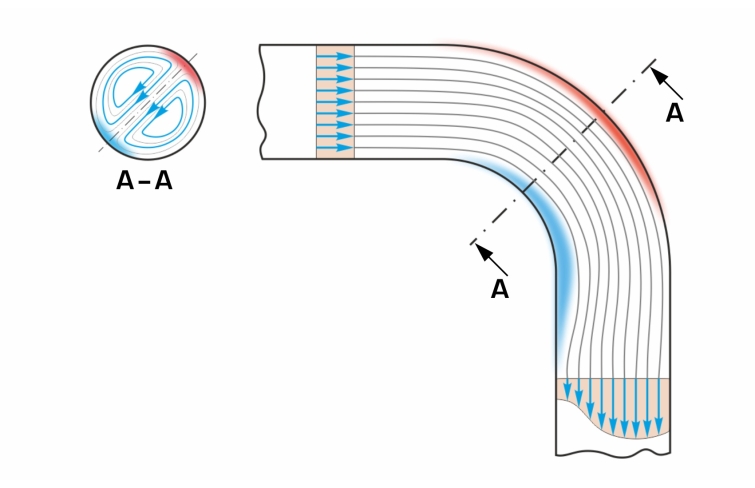

Pressure losses in pipe sections can have various causes, such as acceleration, deceleration, deflection or friction. Pressure loss is often caused by a combination of several factors. This must be taken into account when designing piping systems.

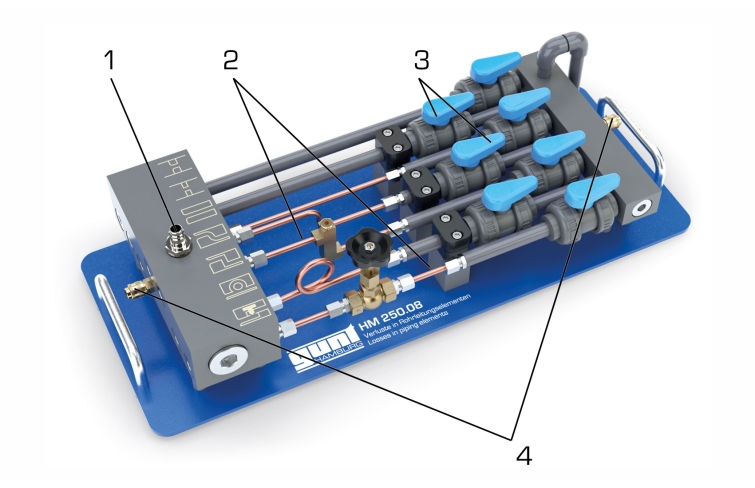

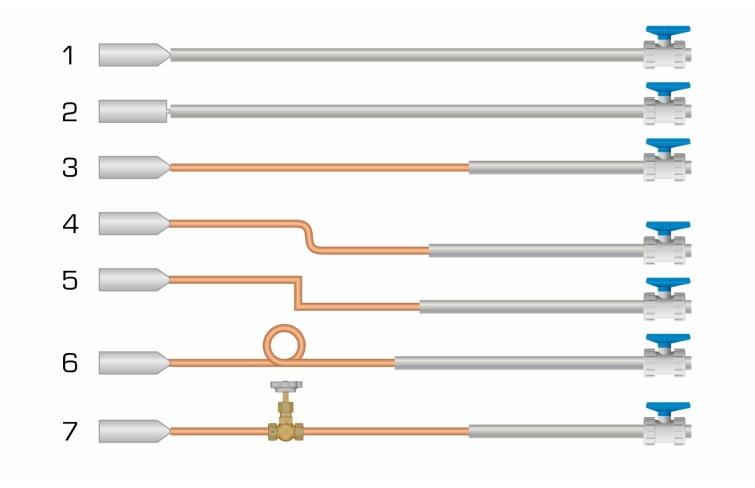

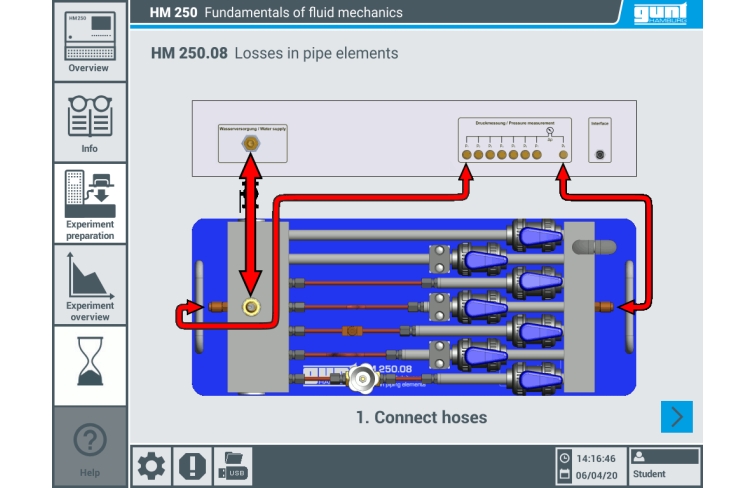

The HM 250.08 unit is used to investigate pressure losses in various pipe sections and pipe elements. The experimental unit contains seven different pipe sections chosen for their didactic qualities (e.g. straight pipe, pipe with needle valve or pipe with S-bend). Each pipe section can be shut off separately by a ball valve.

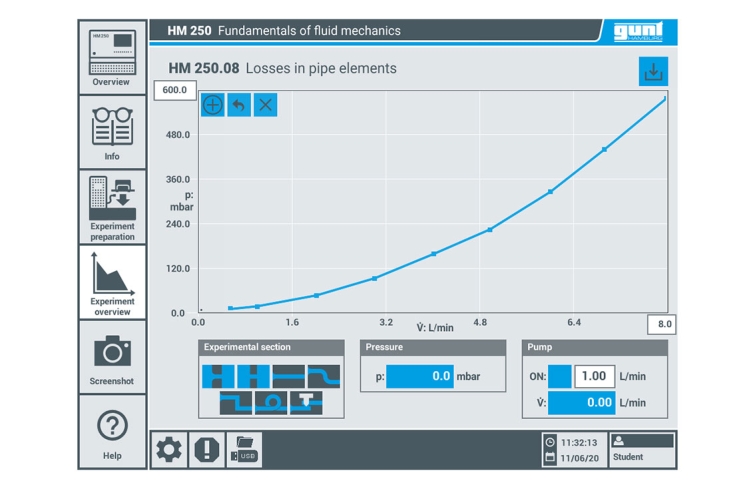

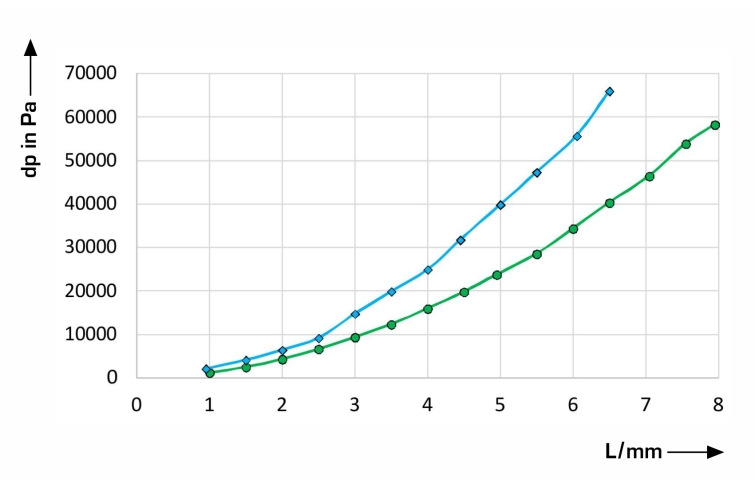

In experiments, the pressure loss coefficient is determined individually in each pipe section. This means that the increase in pressure loss can be precisely attributed. By comparing the pipe sections, the change in pressure loss is specifically elaborated. The opening characteristics of the ball valve and needle valve shut-off devices are also recorded. The losses in the connecting pipes are negligible and are assumed to be the same in all sections.

The accessory HM 250.08 is easily and securely positioned on the worktop of the HM 250 base module. Via RFID technology the accessories are automatically identified, the appropriate GUNT software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments and displays the measured values graphically. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection. The base module supplies the water and is used to adjust the flow rate. The base module is also used to measure the flow rates and the pressures.