Wave energy converters use the energy from continuous wave movements for the environmentally friendly production of electricity. They can supply electrical energy along the coast, in particular to remote locations. Structurally they are easy to integrate into moles, harbour walls and coastal protection systems.

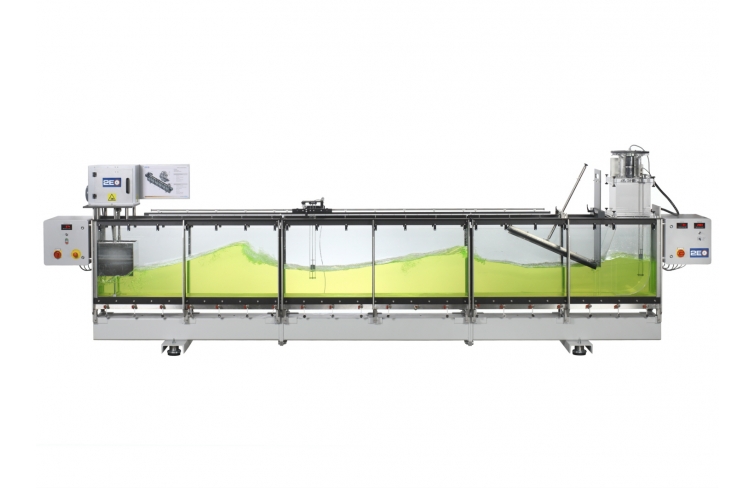

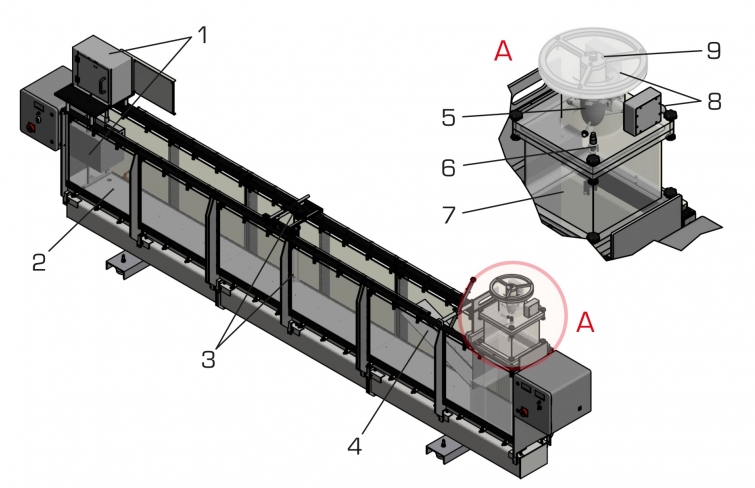

ET 270 is a laboratory-scale wave energy converter consisting of a wave generator, a wave flume and the OWC wave energy converter with turbine unit.

To generate waves in the wave flume, a displacer is moved up and down by an adjustable crank drive. The height of the waves is varied by changing the lift of the displacer. The speed of the motor sets the frequency of the waves. At the end of the wave flume a baffle plate guides the waves into the wave energy converter.

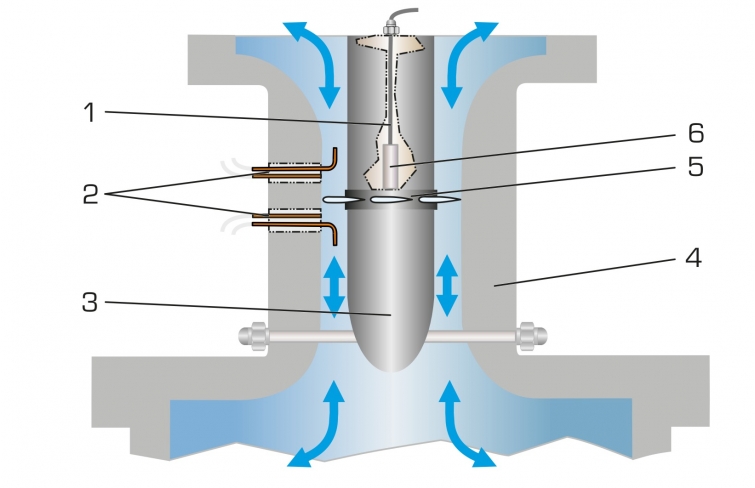

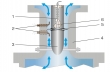

The OWC wave energy converter consists of a chamber and the turbine unit. The initiated, continuous wave motion produces an oscillating water column (OWC) within the chamber, which causes the air mass above it to move. The air flow generated in this way drives the Wells turbine. Wells turbines work independently of the direction with respect to the inflow: the flow energy is converted during both the upward and downward movement of the air.

A DC motor is connected to the turbine and is used to start the turbine up. Upon reaching a set speed, this then acts as a generator and produces electricity.

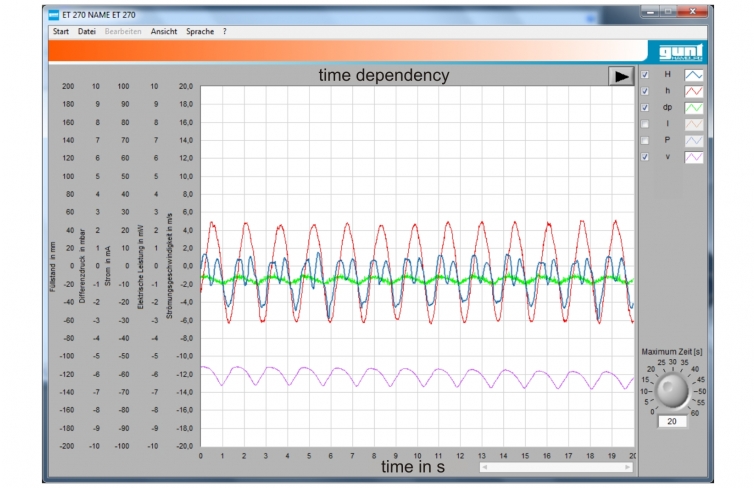

The water level, and thus the wave height, can be measured along the wave flume with a movable wave measuring device with level sensor. Inside the chamber there is another device with level sensor used to measure the movement of the water column. Pressure measuring points in the turbine housing are used to determine the flow velocity of the air movement. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included.