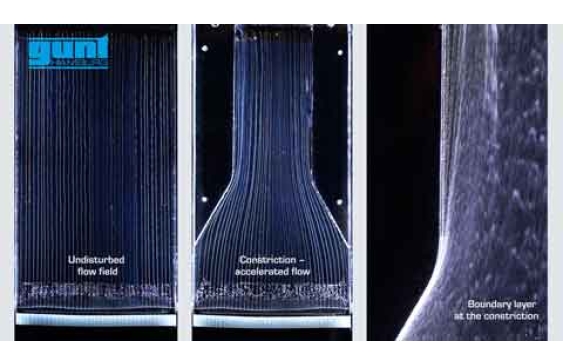

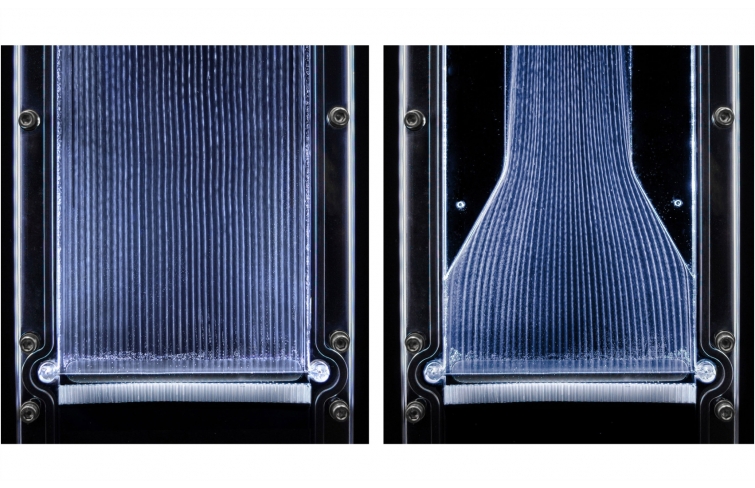

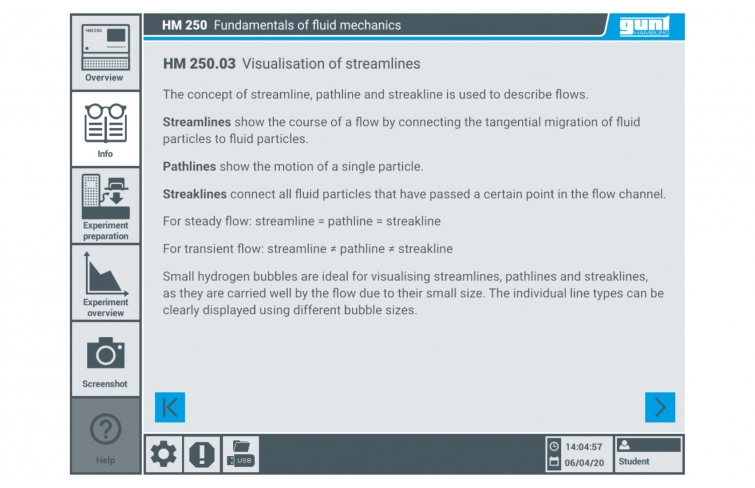

The laminar, two-dimensional flow in the HM 250.03 flow channel represents a good approximation to the flow of ideal fluids: the potential flow. Fine gas bubbles are ideal for visualising streamlines. Due to their small size, they are particularly well carried along the flow.

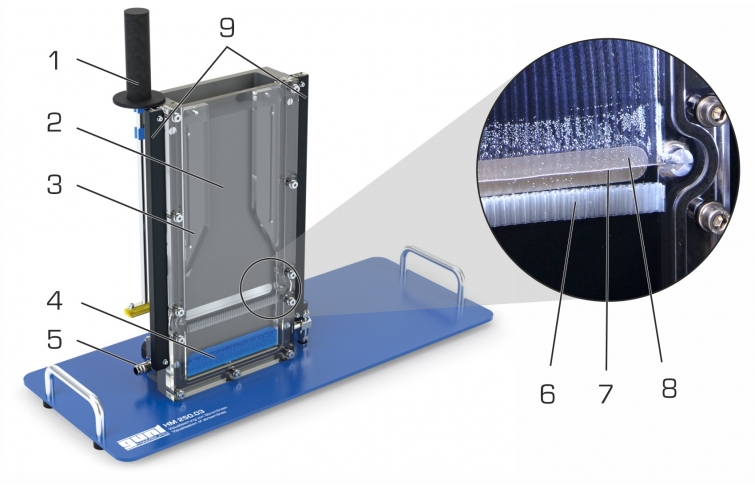

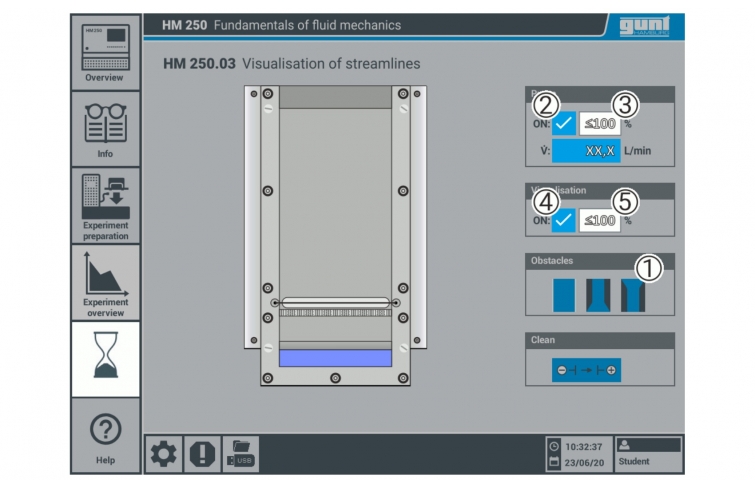

The HM 250.03 contains a vertical experimental section into which models are inserted to generate changes in cross-section. Water passes through the experimental section from bottom to top. Electrolytically generated hydrogen bubbles rise with the flow and thus visualise the streamlines by means of LED lighting.

The hydrogen bubbles are produced electrolytically at a cathode made of thin platinum wire. A stainless steel plate serves as the anode. The small bubbles that detach from the platinum wire are carried along by the flow and create flow lines. The flow lines follow the streamlines of the water.

In experiments, the concept of streamlines, flow lines and strike lines is developed on the basis of the different bubble sizes. The generated flow lines allow conclusions on the flow. If the flow velocity increases, the distance between the flow lines will decrease.

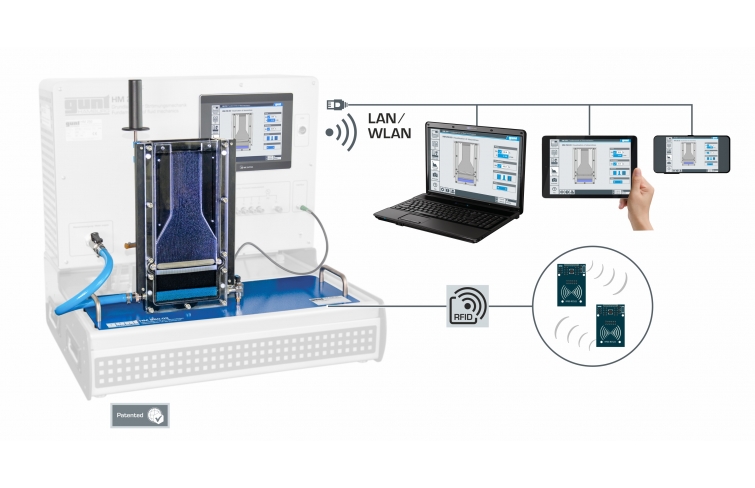

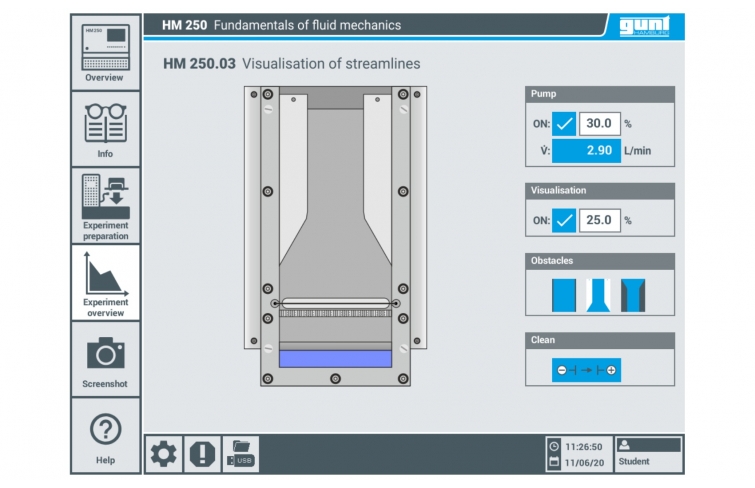

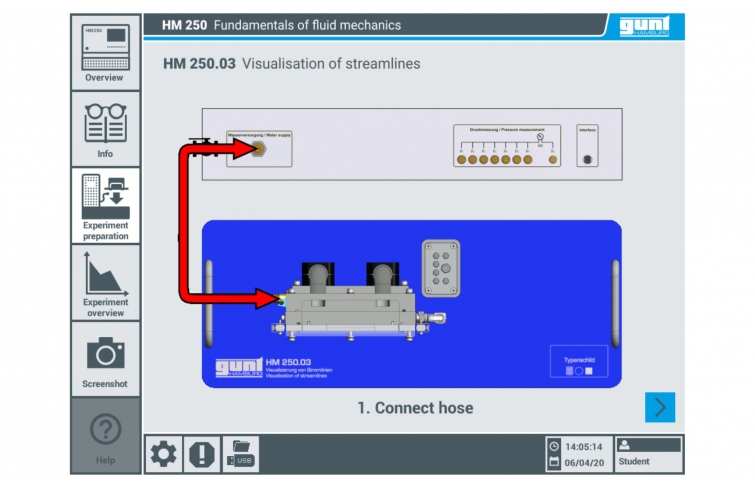

The accessory HM 250.03 is easily and safely positioned on the worktop of the HM 250 base module. Via RFID technology the accessories are automatically identified, the appropriate GUNT software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection. HM 250 supplies the water and is used for flow rate adjustment and measurement. The current for electrolysis can also be adjusted via the base module.