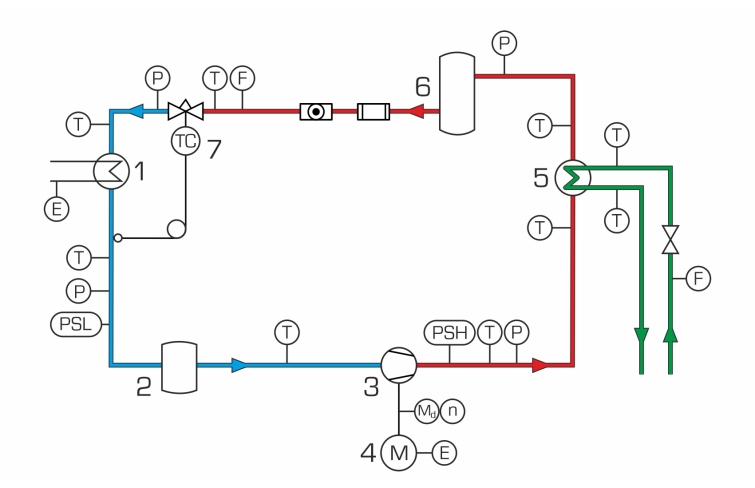

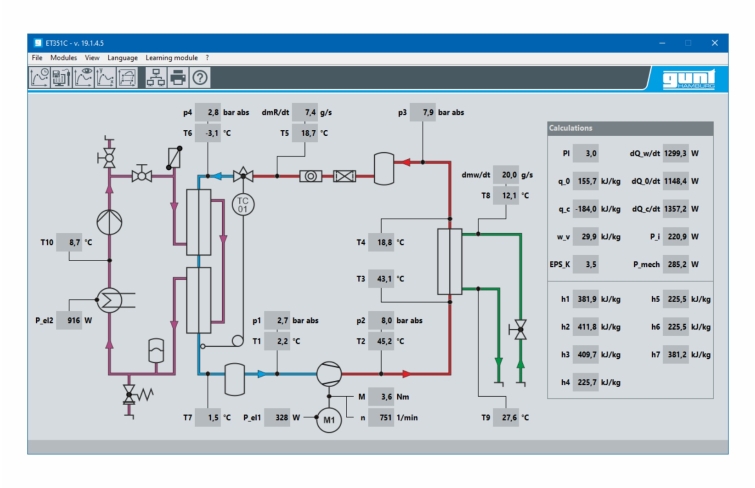

In this trainer, great care was taken to make the thermodynamic processes in the refrigeration system as transparent as possible. The capacities of compressor, evaporator and condenser can be measured. Pressure and temperature measuring points are located at all the relevant locations to also allow for the pressure and heat losses in a refrigeration system to be investigated in detail.

The refrigeration circuit of ET 351C contains an open compressor with variable speed, a water-cooled condenser, a thermostatic expansion valve and an evaporator heated by a hot water circuit.

The compressor is driven via a pendulum bearing motor with frequency converter for speed adjustment. A force transducer permits the measuring of the drive torque. Using the speed the mechanical drive power of the compressor can thus be determined. The electrical heating power of the hot water circuit can be freely adjusted and is displayed. The condenser capacity is measured via the cooling water flow.

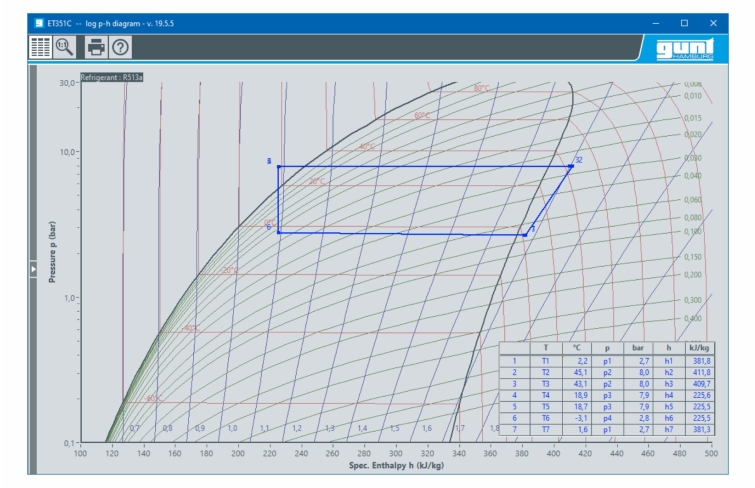

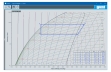

The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included. The software allows for the process to be represented in the log p-h diagram and displays the key characteristic variables of the process, e.g. compressor pressure ratio and coefficient of performance.