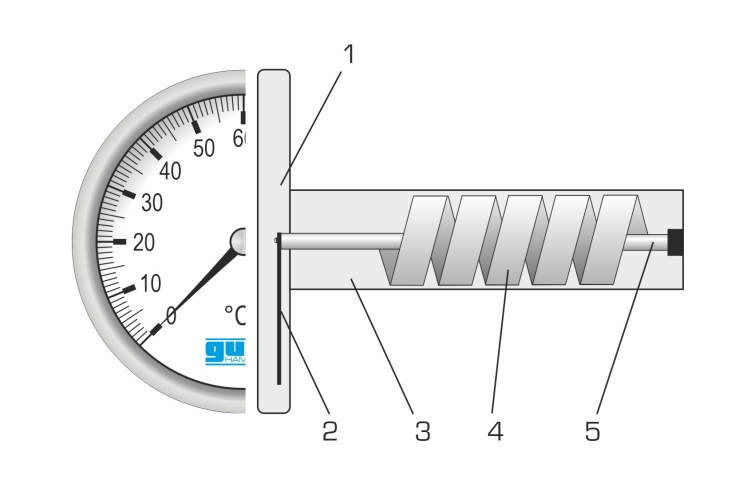

Different physical processes are used to measure temperatures. Temperatures can be read off directly on a scale, e.g. by the expansion of a measuring medium. In industry, temperatures are often measured electronically. The advantage of electronic measurement is that further processing or transmission of electrical signals to remote locations (controllers, external displays) is easier.

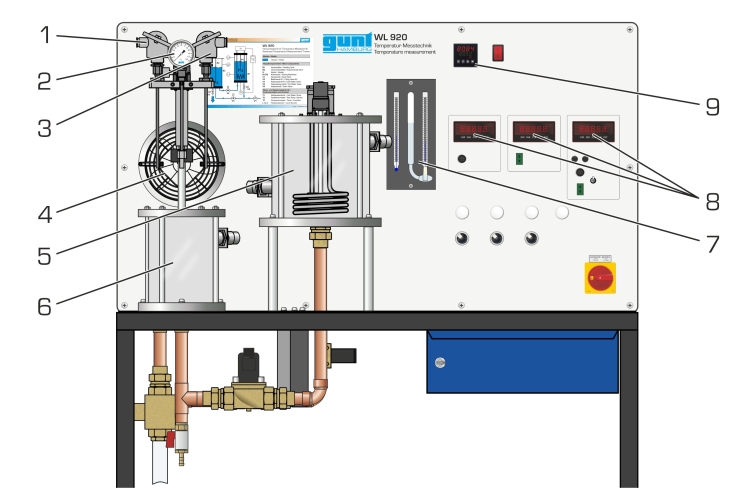

The WL 920 trainer can be used to carry out and compare different temperature measurement procedures. Non-electrical methods are investigated with a liquid thermometer and a bimetallic thermometer. For electrical temperature measurement, a thermocouple type K, a Pt100 resistance thermometer and a thermistor NTC are supplied. A psychrometer with two liquid thermometers is used to measure relative humidity.

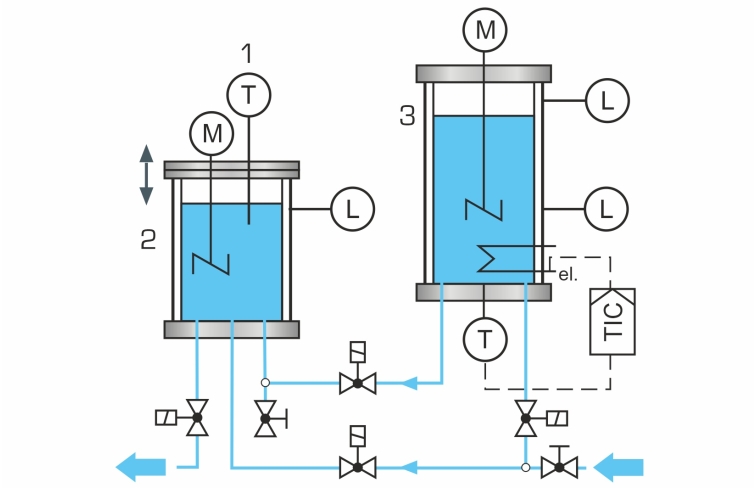

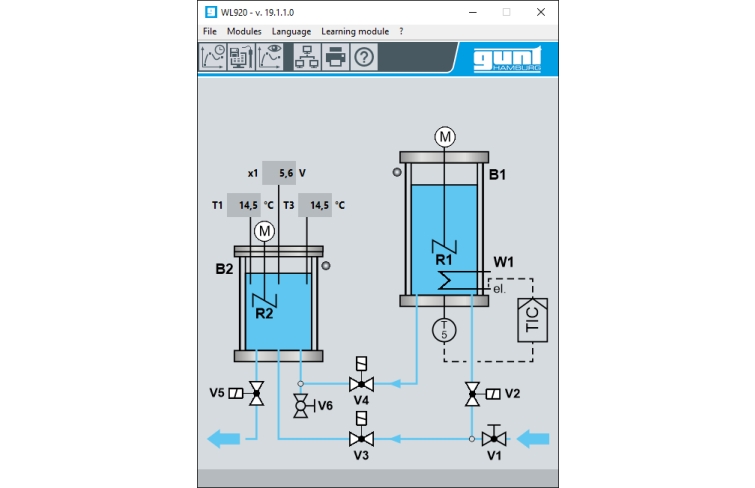

The temperature sensors to be examined are attached to a height-adjustable device above the experimental tank. A fan ensures almost constant ambient conditions. A second tank with electronically controlled heater supplies water temperatures up to approx. 80°C. The heated water at a specified temperature is fed into the experimental tank. By lowering the height-adjustable device, the temperature sensors are immersed in the water for measurements.

In order to vary the response, the temperature sensors of the thermocouple and the resistance thermometer can be inserted into thermowells made of copper or stainless steel.

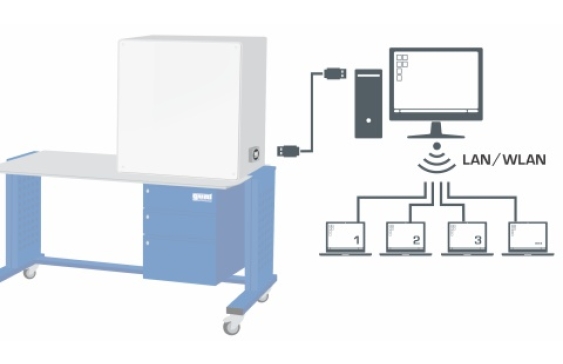

The measured values of the liquid thermometer, bimetallic thermometer and psychrometer are read in analogue form. The measured values of the of the electric temperature sensors are displayed digitally and additionally transferred directly to a PC via USB. With the help of the GUNT software supplied, the temperatures are logged in a measurement record over time, thus documenting the different time behaviour. Defined temperature jumps and steady and transient temperature behaviour can be studied.