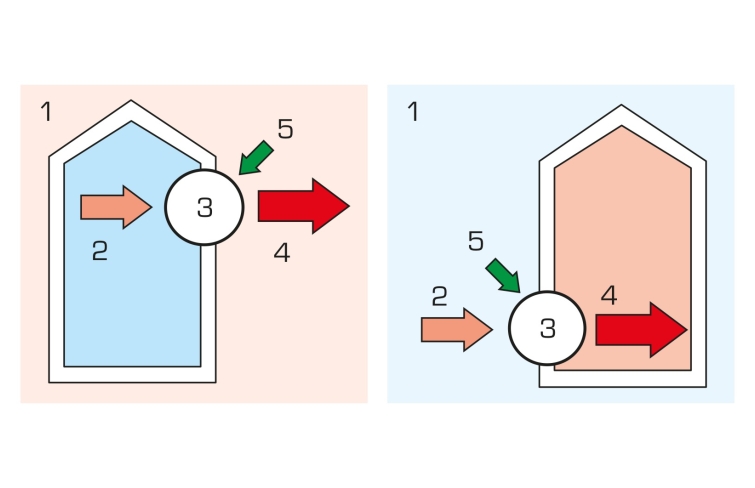

The purpose of a refrigeration system is the cooling of materials and products, e.g. to protect food from spoiling. Cooling can be described as a process in which heat is removed from the environment.

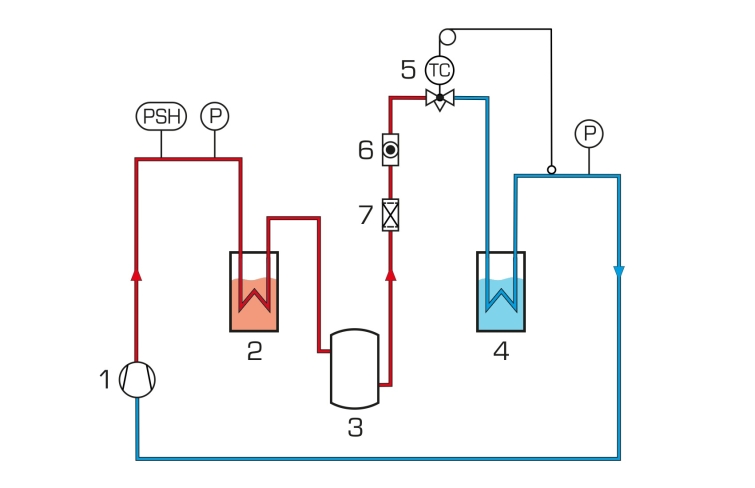

A commonly used refrigeration system is the so-called compression refrigeration system. In this system refrigerant flows through four main elements: compressor, condenser, expansion element and evaporator. The refrigeration system uses the fact that the refrigerant has a low boiling point at low pressure. This means that evaporation takes place on the low pressure side. During the evaporation of the refrigerant heat is removed from the environment and it is cooled. The condensation takes place on the high pressure side after the evaporator. Here the heat is discharged into the environment. If not the cooling effect but the discharged heat is used, this is called a heat pump.

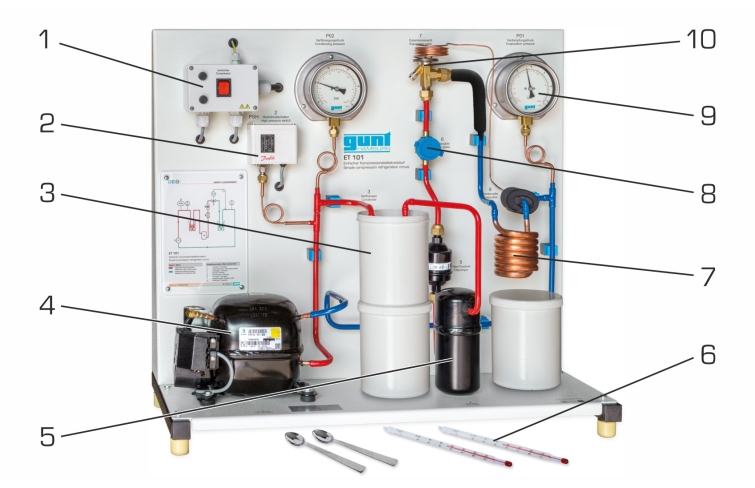

The setup of ET 101 represents a simple compression refrigeration system. Evaporator and condenser have been designed as a pipe coil with each end immersed in a water-filled tank. The water simulates the environment. A thermostatic expansion valve serves as expansion element. Two manometers indicate the two system pressures on the high and low pressure sides. On an additional scale on the manometer the evaporation temperature of the refrigerant is indicated. Two thermometers measure the temperature of the water in the tanks.

This allows for calculations of the amount of heat removed from the environment (evaporator, cold water) and added to the environment (condenser, hot water). A sight glass indicates the aggregate state of the refrigerant upstream of the expansion valve.