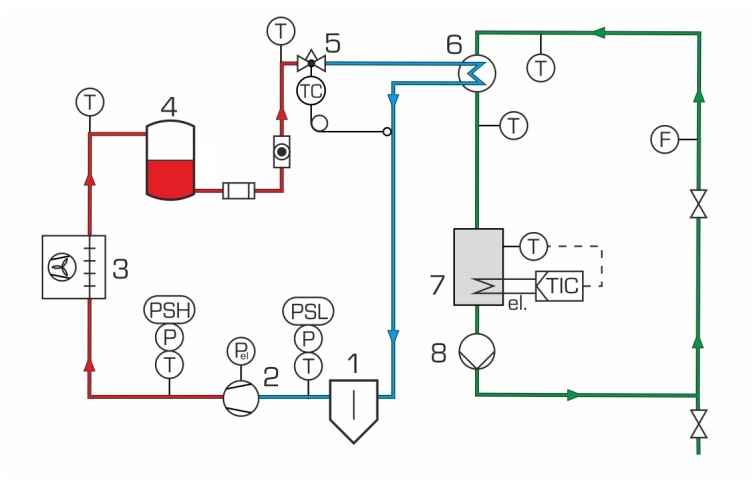

ET 400 examines a refrigeration circuit under an adjustable load. The refrigeration circuit consists of a compressor, a condenser with ventilator, a thermostatic expansion valve and a coaxial coil heat exchanger as evaporator. A water circuit serves as load, consisting of a tank with a heater and a pump. The temperature in the tank is adjusted at a controller.

The purpose of this refrigeration circuit is the production of cold water. The water flows through the jacket of the coaxial coil heat exchanger, transfers heat to the refrigerant and thereby cools down.

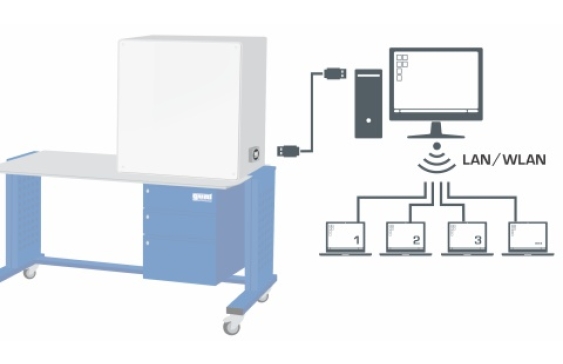

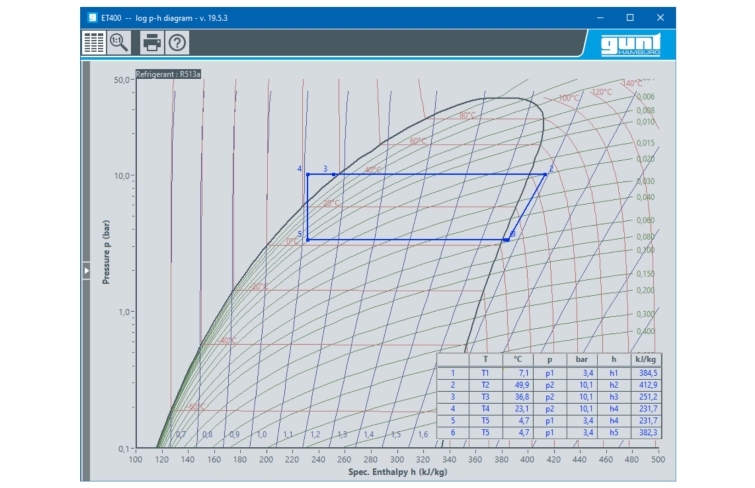

All relevant measured values are recorded by sensors. The simultaneous transmission of the measured values to a data recording software enables easy analysis and the representation of the process in the log p-h diagram. The GUNT software provides exact data on the condition of the refrigerant, which is used to calculate the refrigerant mass flow rate accurately. The calculation therefore gives a much more accurate result than measurement using conventional methods. The software also displays the key characteristic variables of the process, such as the compressor pressure ratio and the coefficient of performance.

The clearly arranged components aid understanding.