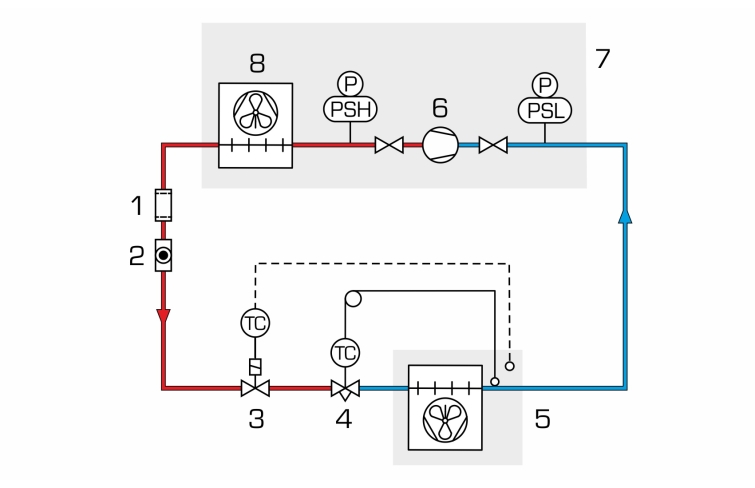

Using MT 210 trainees can learn working within a complex project. This involves the planning, implementation and checking of processes related to assembly, commissioning and maintenance. The assembly relates to refrigeration installation: installation of the LP and HP pressure switches, the expansion valve and the pipework of the refrigeration circuit. The pipe joints are not soldered but bolted. The electrotechnical installation includes the wiring and connection of all units and switching elements.

For assembly the tool set ET 150.02, for commissioning the system the filling and evacuation equipment ET 150.01 are required.

The fully assembled system MT 210 represents a fully functional, temperature-controlled refrigeration system with refrigeration chamber and electrical thermostat. Repeated assembly and disassembly are possible.

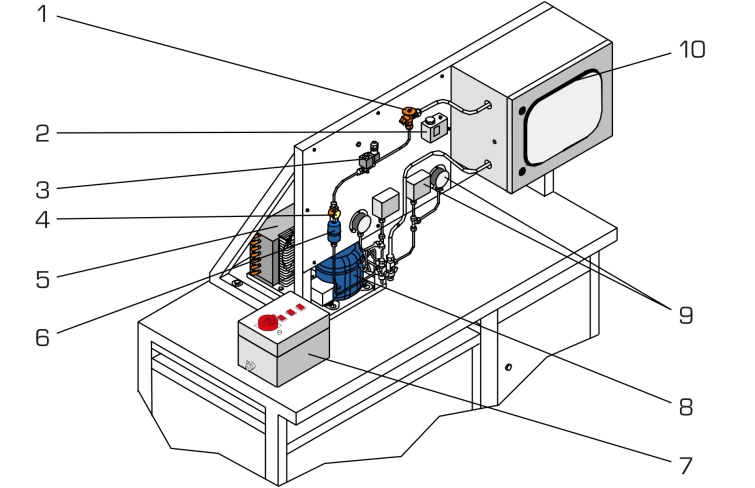

The experiment is arranged on a workbench with drawers for storing the components and tools. Assembly panel and refrigeration chamber are mounted on a frame. Frame, condensing unit and switch cabinet are bolted permanently to the working surface. The refrigeration and electrical components are attached to the aluminium assembly panel.