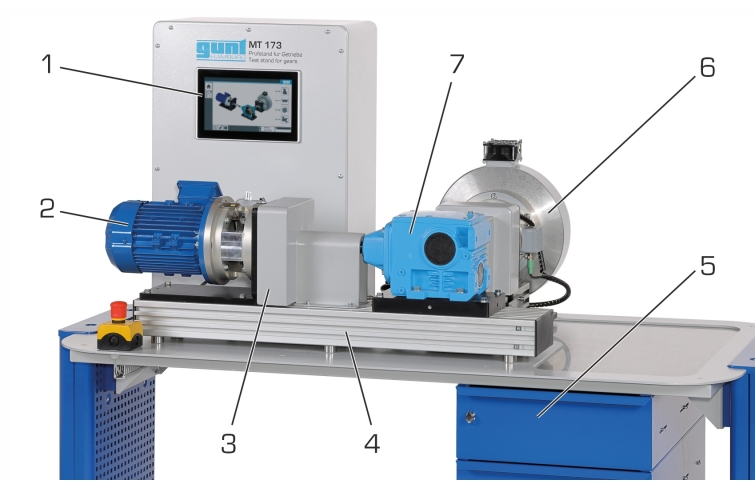

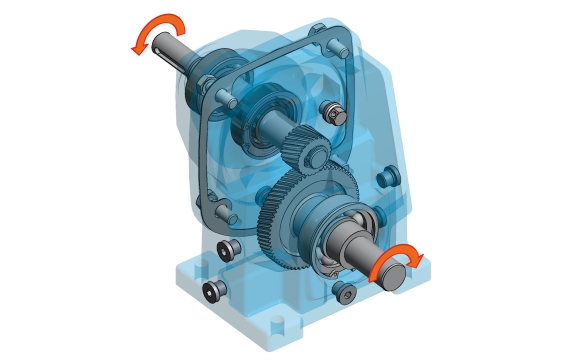

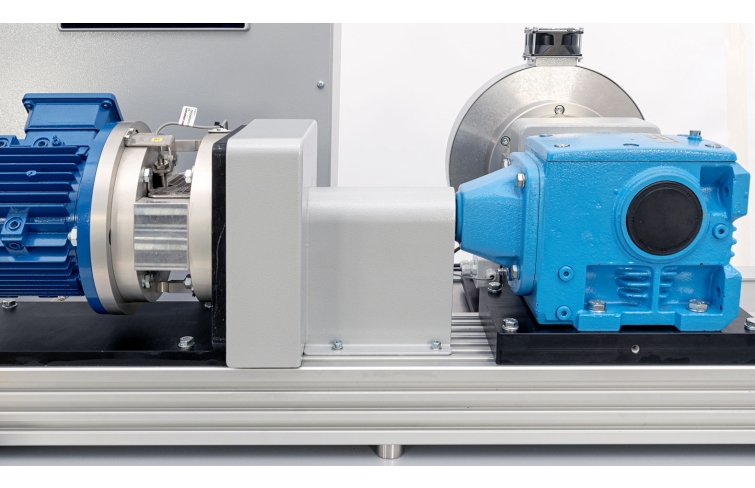

The MT 173 unit is used to investigate the functionality of different gears. The test stand consists of a drive unit and a brake unit. Four different gears are available as accessories. Driving and braking power are calculated to determine the efficiencies. The components used are common in drive systems and therefore have a high level of practical relevance.

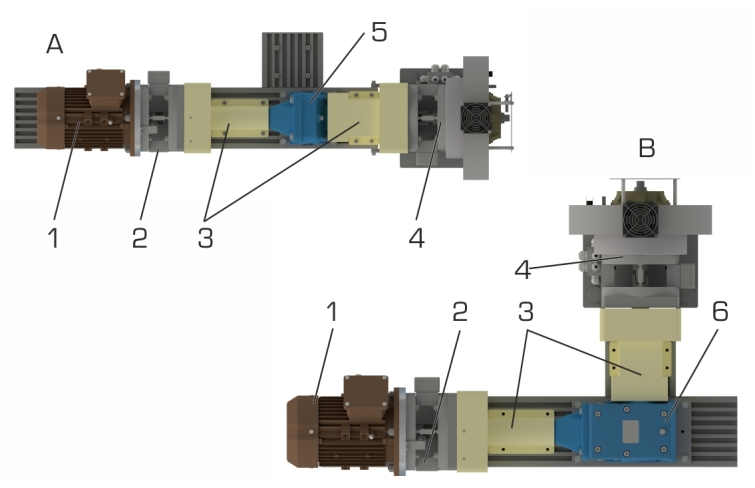

A three-phase motor with variable speed via frequency converter serves as the drive unit. An air-cooled magnetic particle brake is used as the brake unit. The constant braking effect can be very finely adjusted via the exciting current; it then serves as a tunable load.

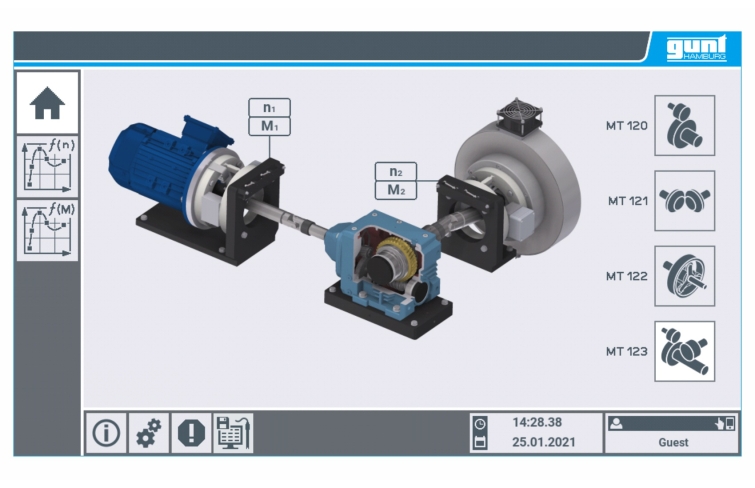

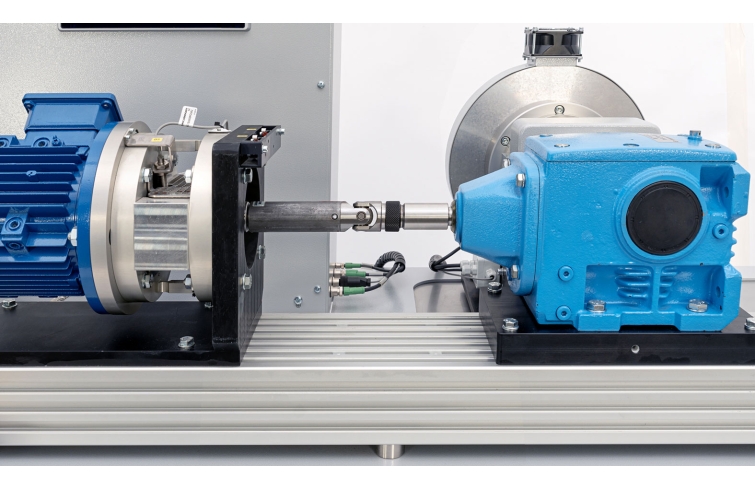

The following gear types are available separately as accessories: spur and worm gear, spur gear, bevel gear and planetary gear. Jointed shafts connect the gears to the motor and brake.

Motor and brake are attached to a fixed torque sensor in order to determine the torques. The speed of the motor is detected contact-free by means of inductive sensors and is displayed digitally.

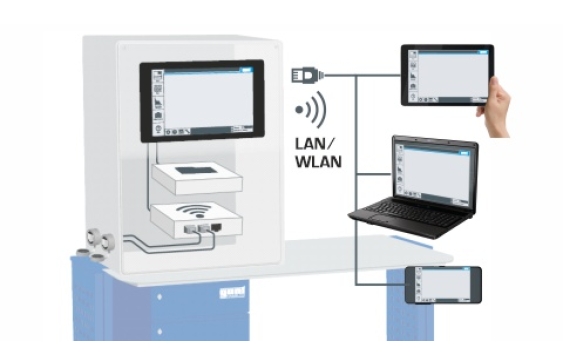

The trainer is controlled by the PLC via touch screen. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on additional end devices (screen mirroring). Measured values are graphical represented on the user interface. Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/ LAN connection to the customer’s own network.