A heat pump usually extracts the energy from the environment. Common energy sources are air, groundwater, ground or river water. An energy source temperature which is as high and constant as possible is the key for high efficiency.

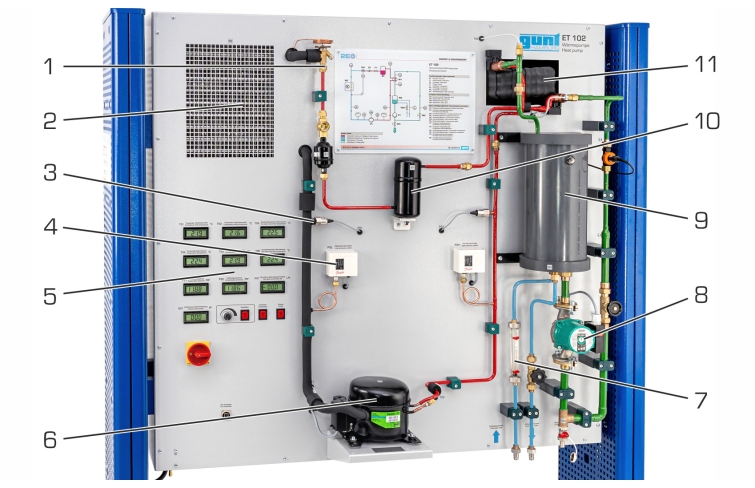

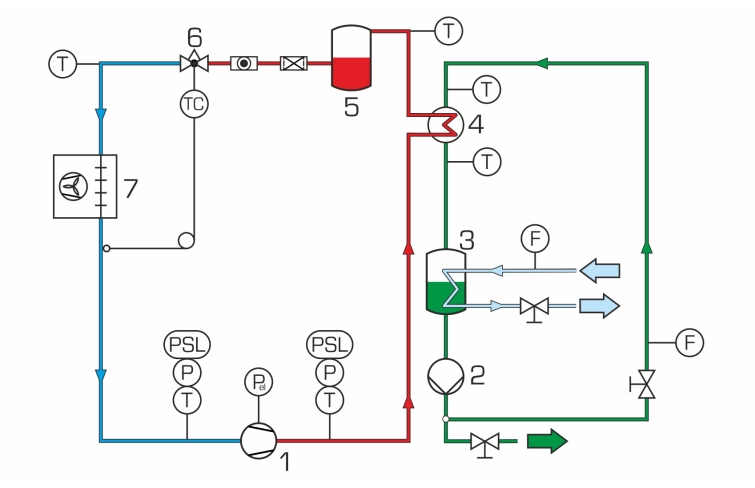

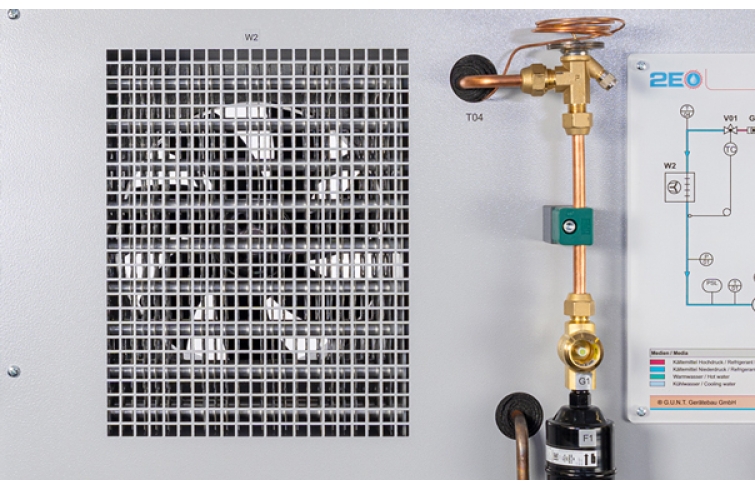

With the air-to-water heat pump ET 102 the ambient heat of the air is used to heat water. The heat pump circuit consists of a compressor, an evaporator with ventilator, a thermostatic expansion valve and a coaxial coil heat exchanger as condenser. All components are clearly arranged in the trainer.

The compressed refrigerant vapour condenses in the outer pipe of the condenser and thereby discharges heat to the water in the inner pipe. The liquid refrigerant evaporates at low pressure in the finned tube evaporator and thereby absorbs heat from the ambient air. The air flow is adjustable via a powerful EC ventilator.

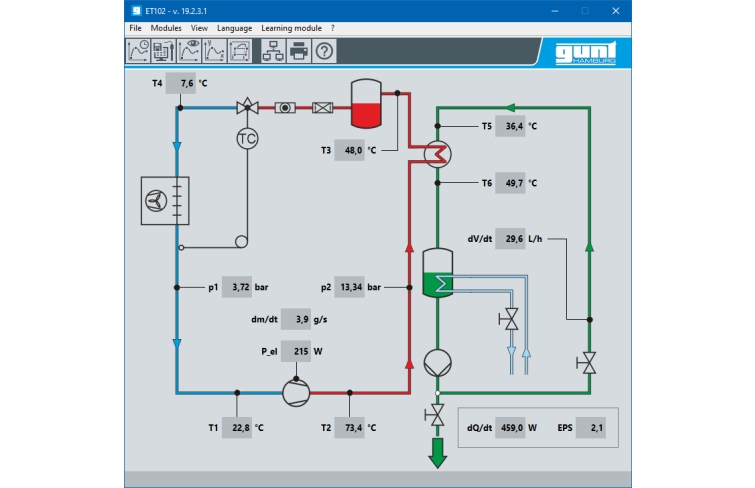

The hot water circuit consists of a tank, a pump and the condenser as heater. For a continuous operation the generated heat is dissipated via an external cooling water connection. The cooling water flow rate is set via a valve and measured.

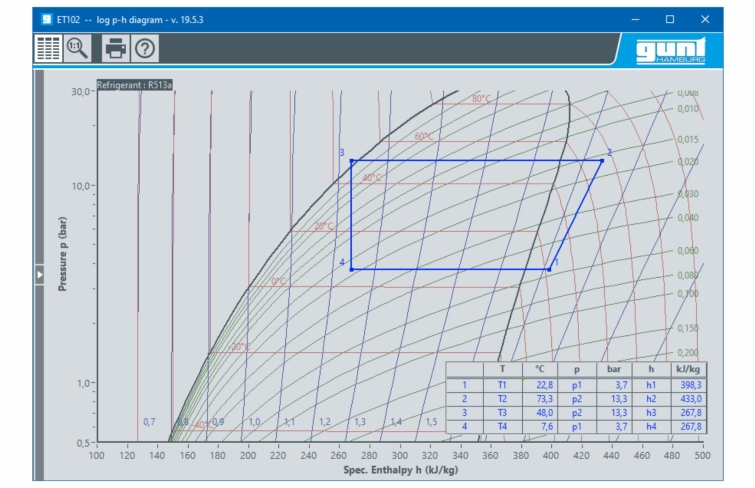

All relevant measured values are recorded by sensors and displayed. The simultaneous transmission of the measurements to a data recording software enables analysis and the representation of the process in the log p-h diagram. The GUNT software provides exact data on the condition of the refrigerant, which is used to calculate the refrigerant mass flow rate accurately. The calculation therefore gives a much more accurate result than measurement using conventional methods. The software also displays the key characteristics variables of the process, such as the compressor pressure ratio and the coefficient of performance.