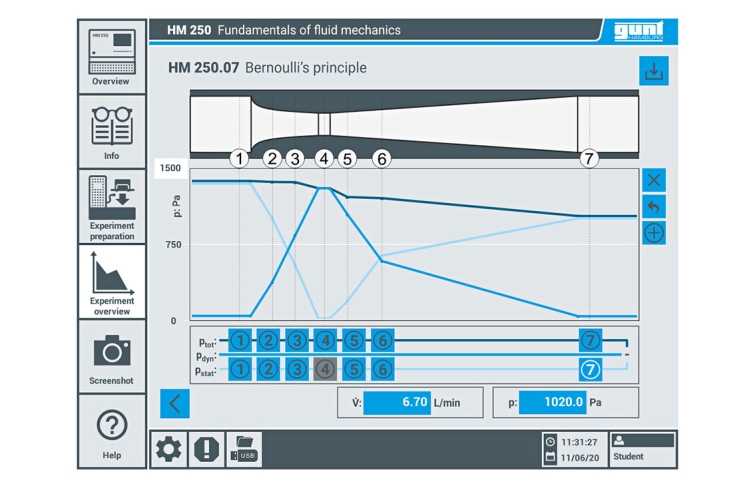

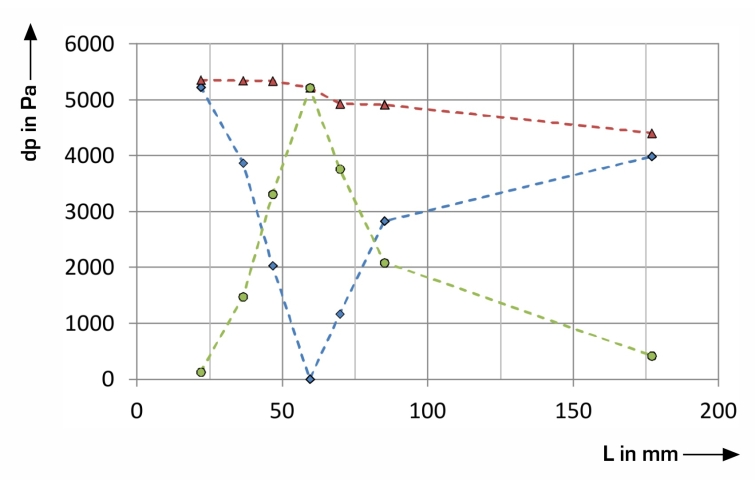

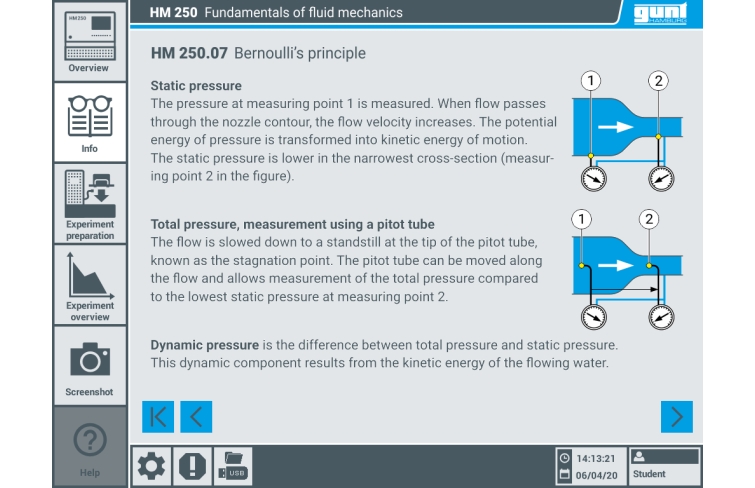

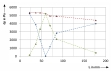

The HM 250.07 accessory is used to investigate the relationship between the flow velocity of a fluid and the different pressures in a Venturi nozzle. If the flow velocity of a fluid increases, e.g. when passing through a nozzle, the static pressure will drop. If the velocity decreases, the static pressure increases. The total pressure remains constant during the velocity change.

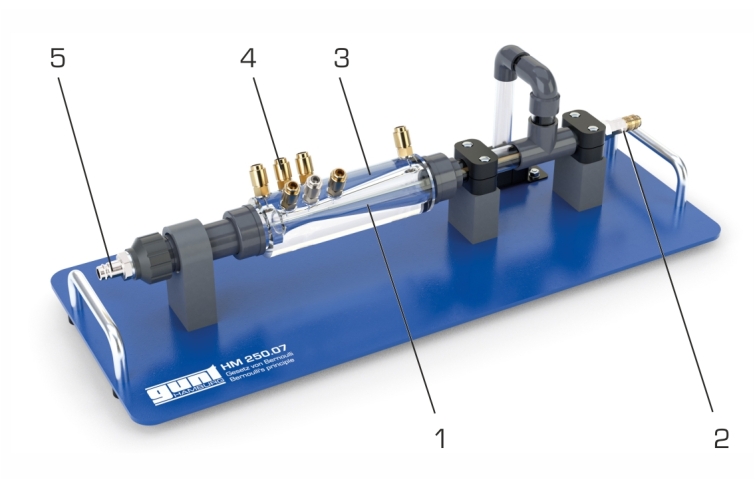

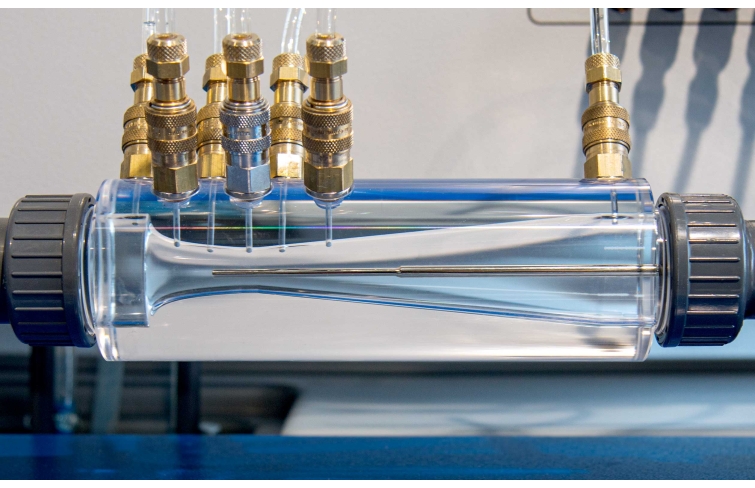

The Venturi nozzle is made of transparent material and is equipped with pressure connections for measuring the static pressure. The relative pressure increase compared to the narrowest cross-section is measured. The total pressure is measured with a Pitot tube which is moved in the nozzle along the flow. The dynamic pressure is determined from the static pressure and the total pressure.

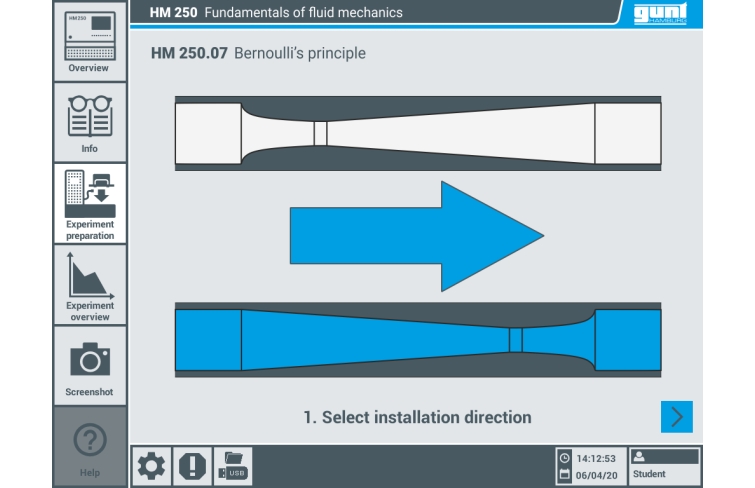

The position of the Pitot tube in the nozzle can be observed. By turning the nozzle, the direction of flow is changed and the nozzle can be used as a diffuser. This allows the comparison of flow losses between a nozzle and a diffuser.

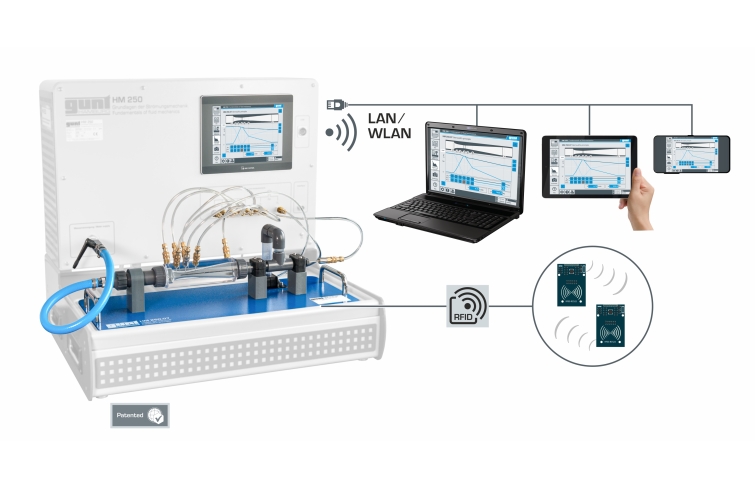

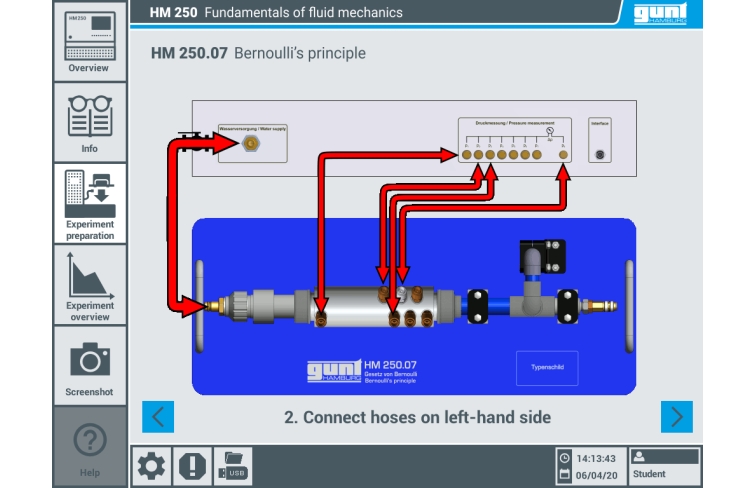

The accessory HM 250.07 is easily and securely positioned on the worktop of the HM 250 base module. Via RFID technology the accessories are automatically identified, the appropriate GUNT software is loaded and an automatic system configuration is performed. The intuitive user interface guides through the experiments and displays the measured values graphically. For tracking and evaluation of the experiments, up to 10 external workstations can be used simultaneously using the local network via LAN connection. The base module supplies the water and is used to measure the flow rate and pressure. The flow and pressure measurements are also measured via the base module.