Driven machines release absorbed mechanical work to a liquid or gaseous medium. They are divided into positive displacement machines and turbomachine according to their function. For large volumetric flow rates the benefits of turbomachines are predominant, such as centrifugal pumps; for small volumetric flow rates piston engines are more likely to be used.

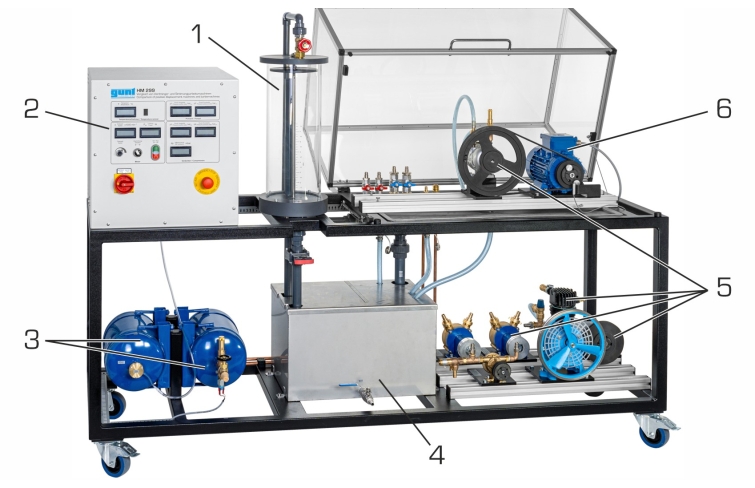

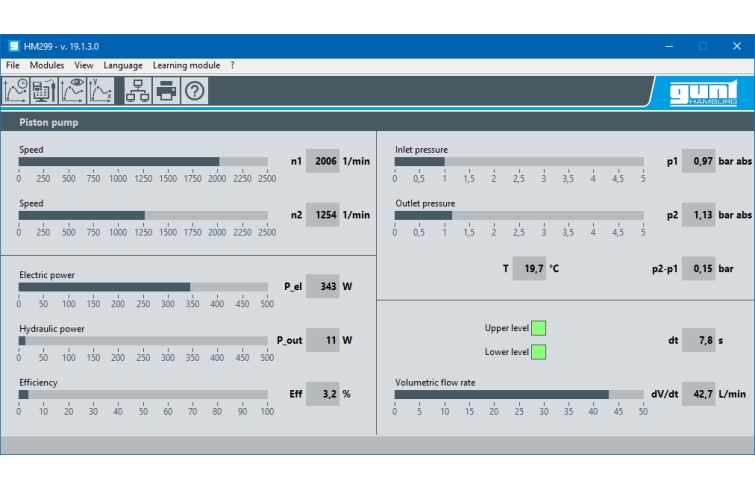

The HM 299 trainer allows the comparison of different machines for liquid and gaseous media. One turbomachine and three different positive displacement machines are supplied. Software for data acquisition and visualisation makes the experiments especially clear and enables fast execution of experiments with reliable results.

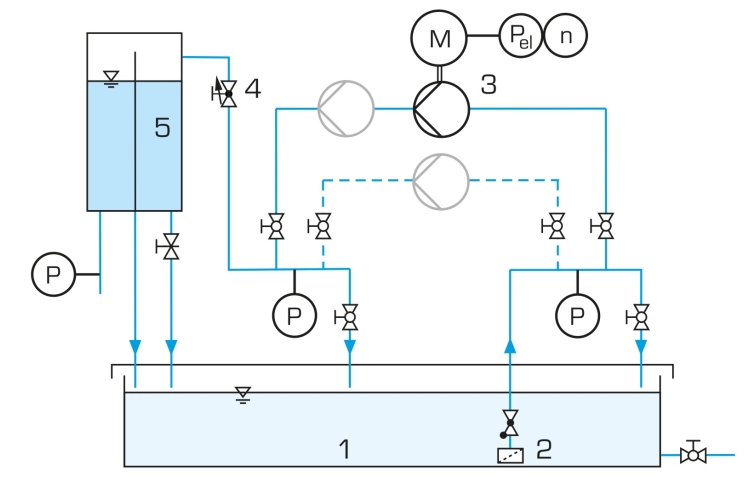

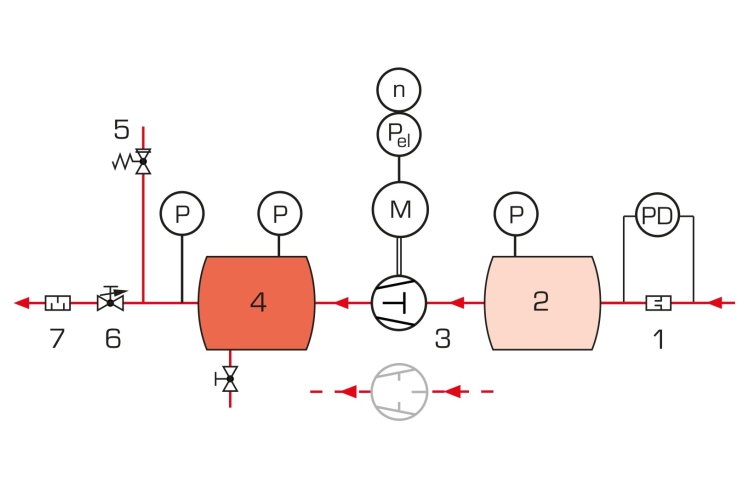

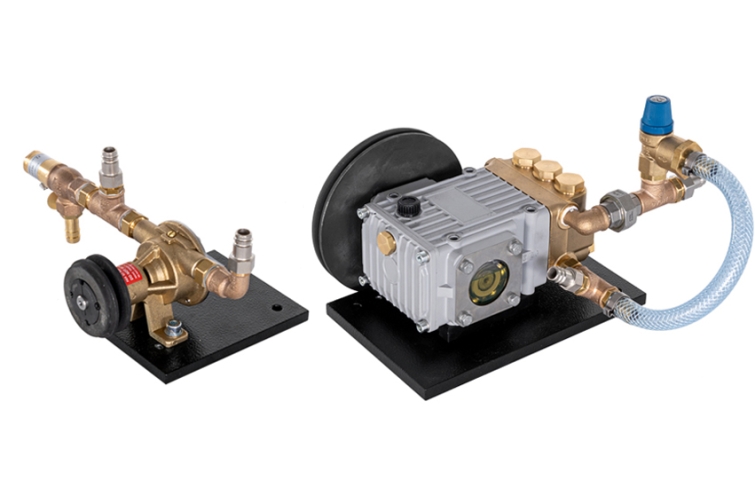

HM 299 includes a drive motor with speed adjustment, belt drive and protective hood, two pressure vessels for experiments with the compressor and two water tanks for experiments with pumps. Each machine is mounted on a plate and can easily be placed in the trainer. The machines are driven by a belt drive. The pumps are connected to a closed water circuit via hoses with quick-release couplings. Sensors measure the pressures at inlet and outlet, temperature, engine speed and engine output. The respective flow rate is measured indirectly via fill level (water) or Venturi nozzle (air).

The measured values are read from digital displays and can at the same time be transmitted via USB directly to a PC where they can be analysed using the software included.