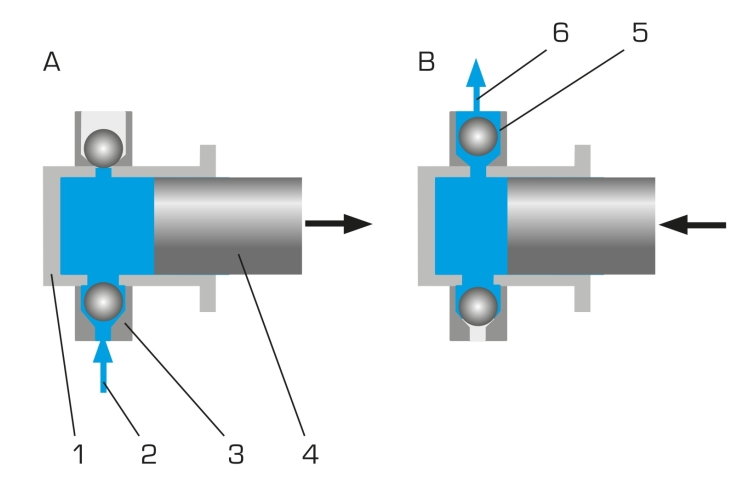

Piston pumps belong to the group of positive displacement pumps. They transport the medium by a reciprocating motion of a piston in the pump working space, called stroke. The stroke creates a suction hence vacuum effect used to deliver the water. Piston pumps are used when high pressures are to be generated. The flow rate of piston pumps is independent of the head and is determined only by speed. Its good suction performance is outstanding.

The experimental unit provides the basic experiments to get to know the operating behaviour and the important characteristic variables of piston pumps.

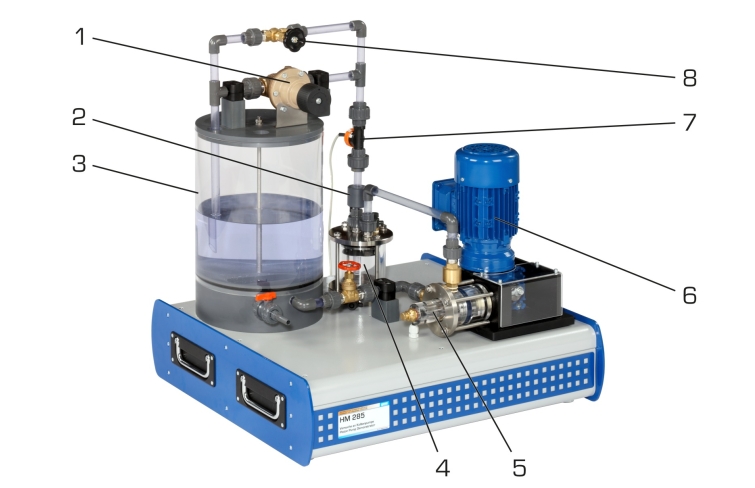

HM 285 features a closed water circuit with water tank, a piston pump with variable speed via a frequency converter and an air vessel. The piston of the pump is mounted in a transparent housing and can be observed during operation. The cycle that takes place (intake and discharge of water) can be shown clearly in the p-V diagram. The pulsating pressure curve of the pump can be damped with the aid of the air vessel. Flow rate and head are adjusted via a needle valve and overflow valve.

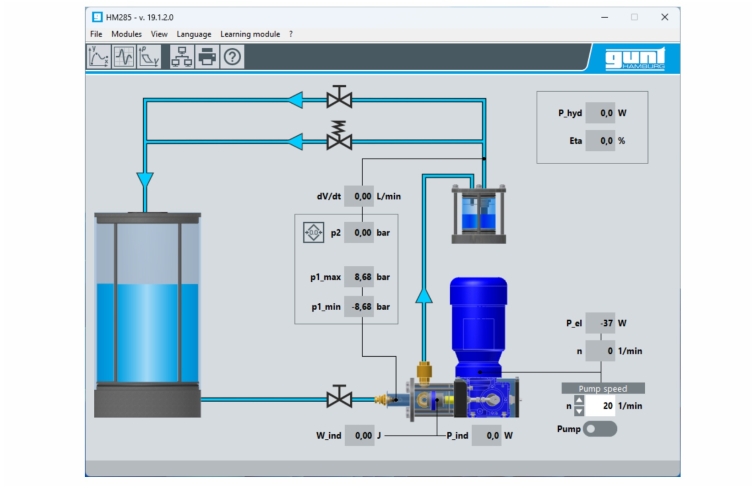

The experimental unit is fitted with sensors for pressure and flow rate. One pressure sensor measures the pressure at the outlet of the pump, another one measures the pressure in the inside of the cylinder. The position of the piston rod is measured by an angle sensor. This allows the determination of the cylinder volume. The microprocessor-based measuring technique is well protected in the housing. The measured values are transmitted directly to a PC via USB where they can be analysed using the software included.

All the advantages of software-supported experiments with operation and evaluation are offered by the GUNT software and the microprocessor.