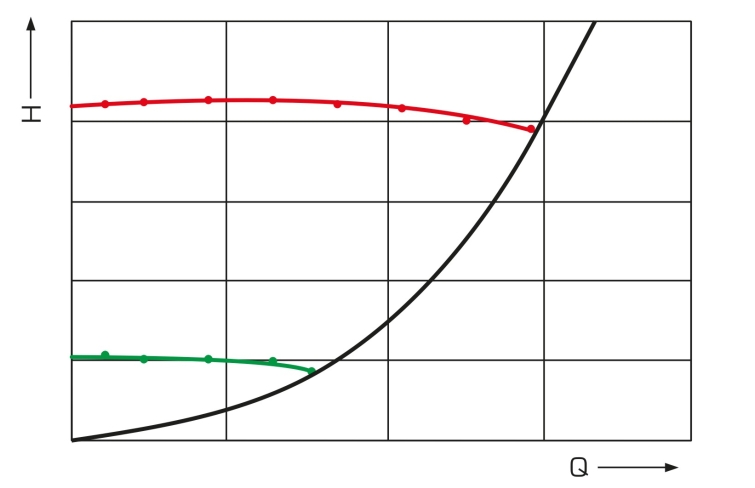

Turbomachines such as pumps and turbines are energy converters. Turbines convert flow energy into mechanical energy and pumps convert mechanical energy into flow energy.

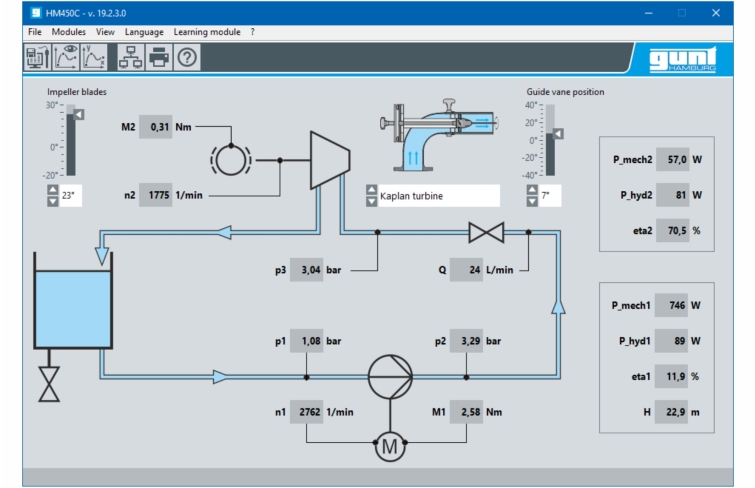

HM 450C can be used to investigate a centrifugal pump. Experiments can be performed on four key water turbine designs: Pelton, Francis, propeller type and Kaplan turbine, available as accessories HM 450.01, HM 450.02, HM 450.03 and HM 450.04.

The closed water circuit comprises a tank, a standard centrifugal pump with variable speed and a flow control valve to adjust the back pressure.

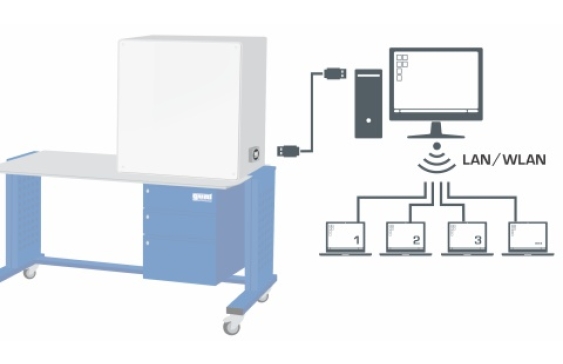

The speed is detected contact-free by means of an inductive displacement sensor on the motor shaft. To determine the drive power, the drive motor is mounted on swivel bearings and equipped with a force sensor to measure the drive torque. Pressures at the inlet and outlet of the pump are measured. The flow rate is measured by means of an electromagnetic flow meter. The measured values are displayed digitally and processed further on a PC. The PC is used to calculate the power output data of the examined turbomachine and to represent them in characteristics.

One of the turbines HM 450.01, HM 450.02, HM 450.03 or HM 450.04 can be placed on top of the storage tank. The centrifugal pump supplies the turbine with water. The measured values of the turbine are transfered via cable to HM 450C. A special feature of HM 450C is the ability to operate pump and turbine at the same time. Relevant measured values are recorded contemporaneously at both turbomachines. Thus the trainer can be used as a pumped storage plant.