The RT 451 – 455 series is constructed entirely from industrial components in order to teach control engineering in a practical manner. The use of smart sensors lays the foundations for Industry 4.0 applications. Smart sensors provide signal processing in addition to the capture of measured values thanks to integrated evaluation electronics. Besides process data, it is also possible to exchange configuration, diagnostic or statistical data. In practice this makes it faster to change over production lines, for example, or enables predictive maintenance.

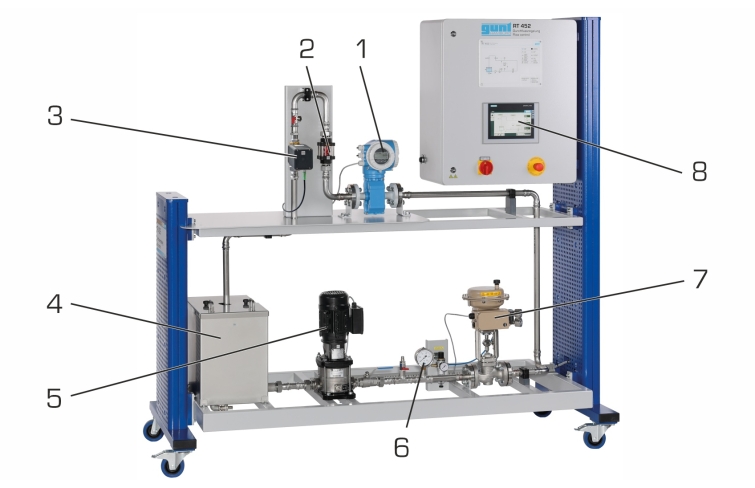

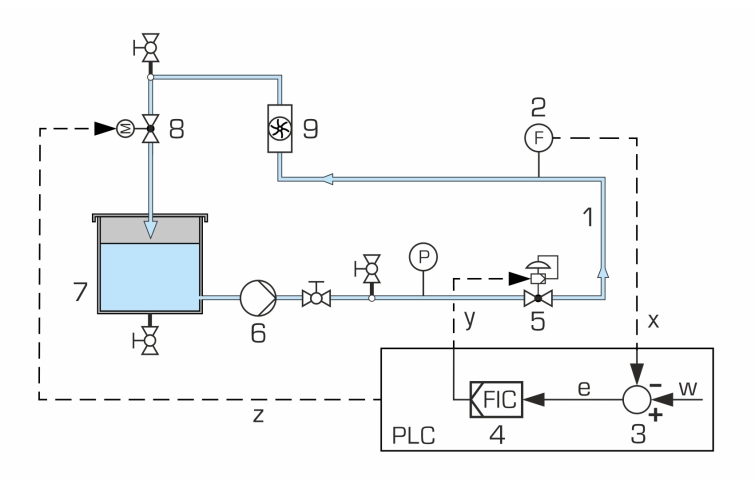

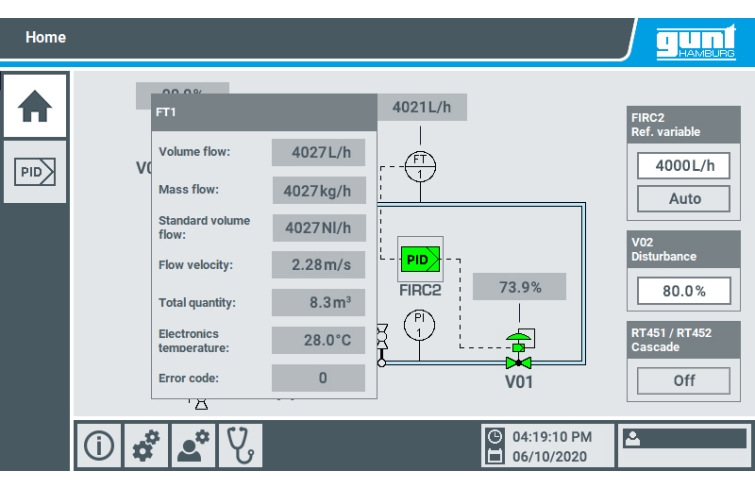

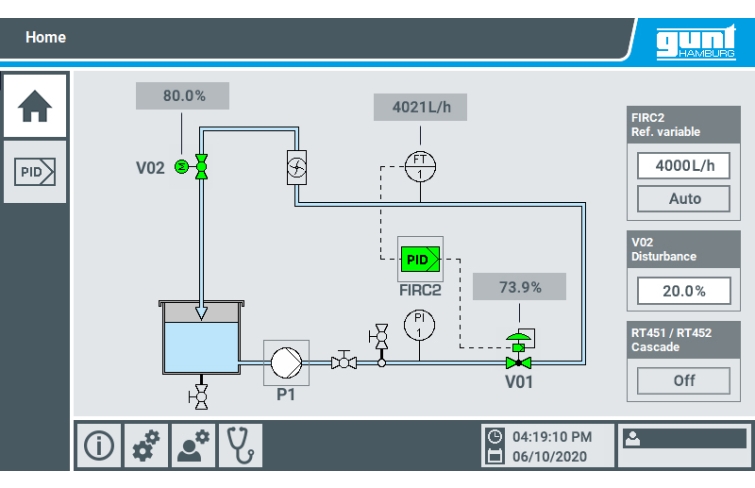

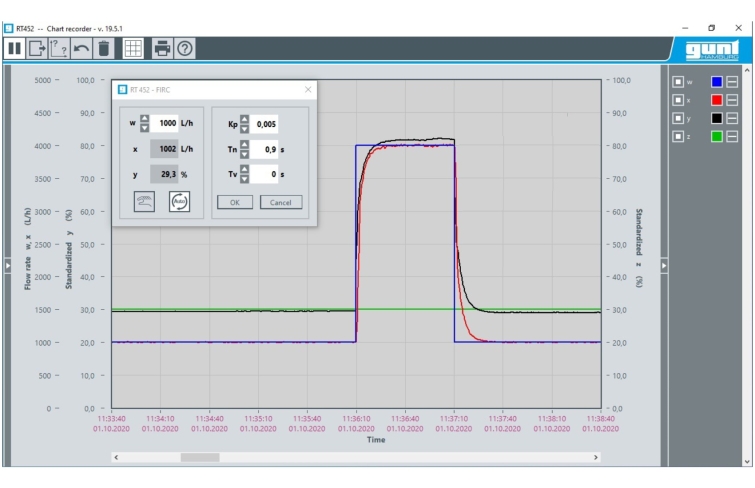

The RT 452 trainer has all components required for an open and closed control loop. The controlled system is a pipe section through which water is pumped. The pipe section contains a smart flow rate sensor as a measuring element, which records the flow rate as the controlled variable. The actuator is an electropneumatic control valve with positioner. Defined disturbance variables can be generated via a proportional valve with motor drive. A separate flow rate indicator visualises the flow through the pipe section.

The flow rate is measured by a smart electromagnetic flow rate sensor. The sensor is connected via Profinet and also makes it possible to transmit the system status.

For further experiments, a cascade control system can be set up together with RT 451.

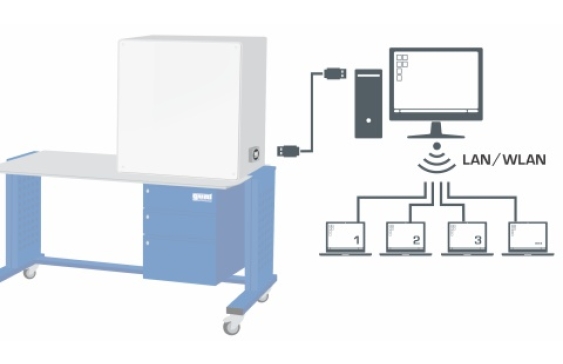

The trainer is controlled and operated via the integrated PLC and the touch screen or via GUNT software (external PC required). The control response is displayed in the form of a time function. The network capable software makes it possible to follow and analyse the experiments at any number of workstations via a LAN/WLAN connection to the local network.