The RT 580 facilitates practical learning in the control of three controlled variables which are commonplace in process engineering.

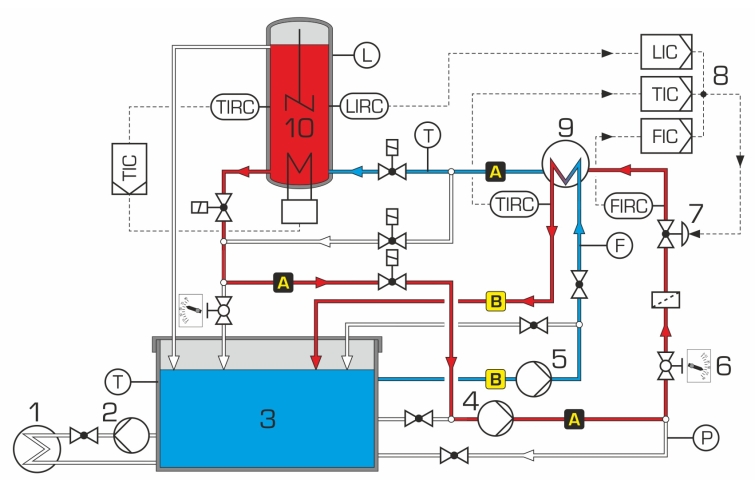

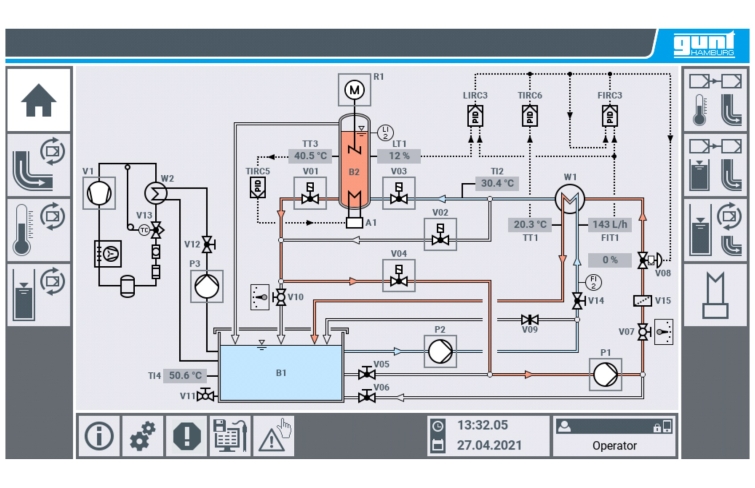

A circuit with a collecting tank, pump and graduated tank is provided for control of level and flow rate. A pneumatic control valve is used as the actuator. There is a valve in the tank outlet to generate a disturbance variable in level control. Cascade control is possible whereby the level in the tank is controlled by way of the flow rate.

Two circuits are used in the control of the temperature. A refrigeration system cools the water in the collecting tank. A pump circulates the water via a heat exchanger (cooling circuit). A heater heats the water in the graduated tank. Another pump also circulates the warm water via the heat exchanger. In the heat exchanger the water in the cooling circuit is heated. The controlled variable is the temperature of the water in the cooling circuit after heating in the heat exchanger. The actuator is the pneumatic control valve which adjusts the flow rate of the warm water. Cascade control is also possible to control the temperature.

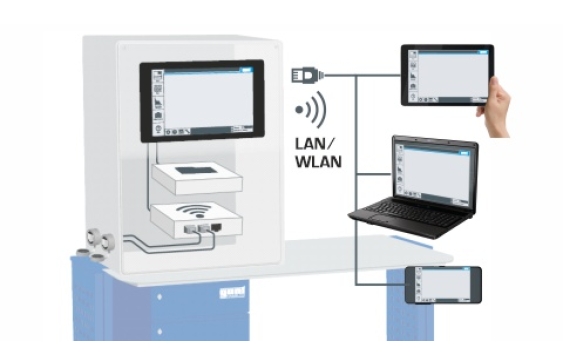

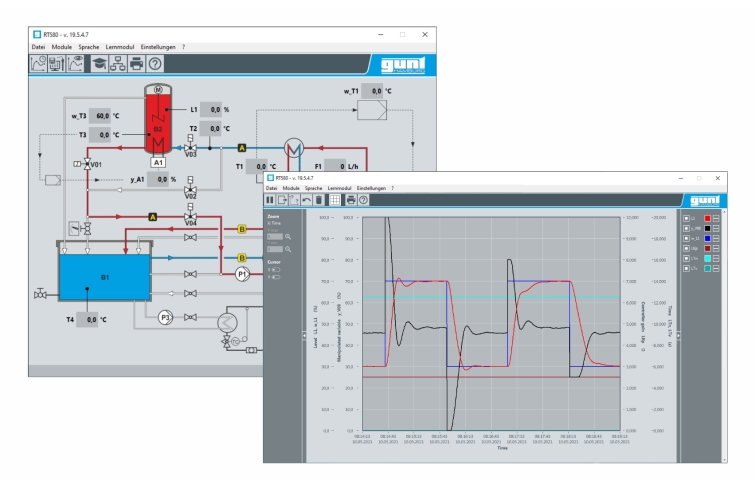

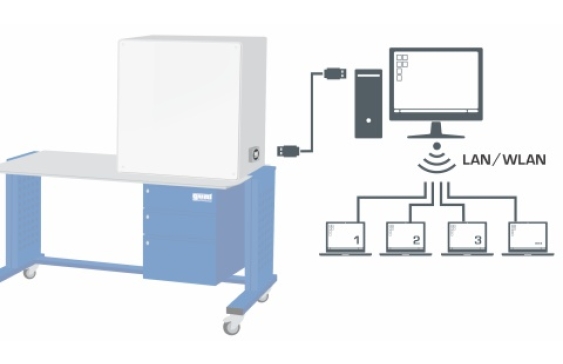

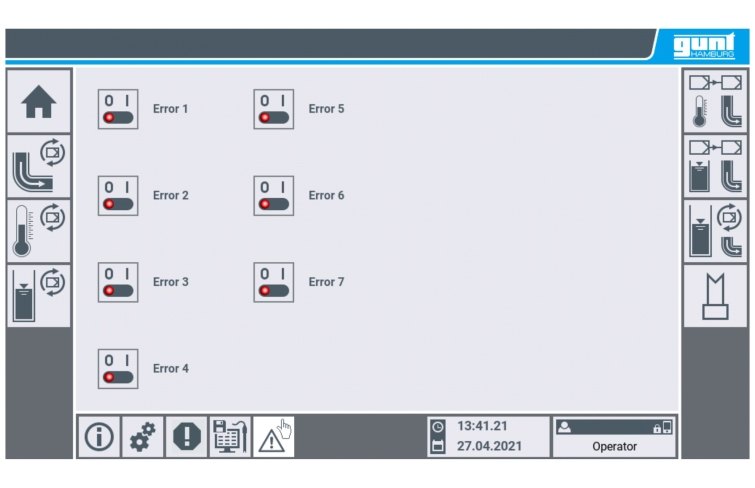

The trainer is equipped with a comprehensive range of functions for measurement, control and operation that are controlled by a PLC: monitoring of safety devices (e.g. a low water cut-off protecting the heater), simulation of typical faults (e.g. failure of sensors or cable breaks), and three controllers which can be employed as the primary controller (master) and secondary controller (slave) in the implementation of cascade control. A touch screen displays the measured values and operating states and can be used to control the trainer. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on additional end devices (screen mirroring). The measured values can be stored internally via the PLC. Access to stored measured values is possible from end devices. Via direct LAN connection the measured values can also be transmitted to a PC where they can be analysed using the GUNT software.