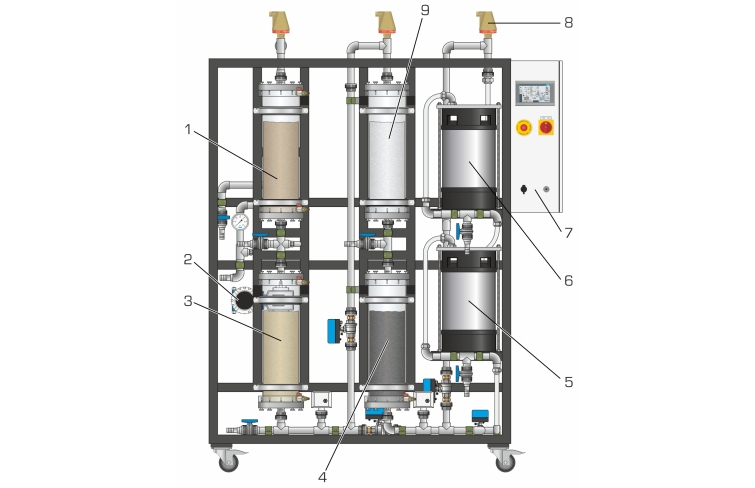

Depth filtration, adsorption and ion exchange are key unit operations in water treatment. CE 581 enables these three operations to be demonstrated.

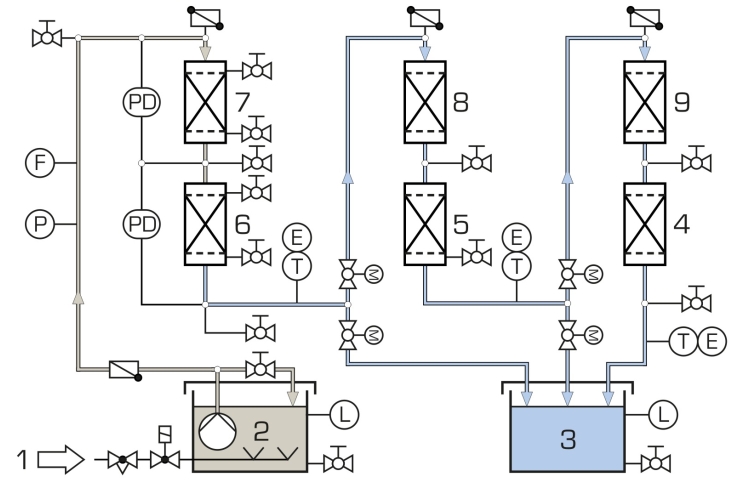

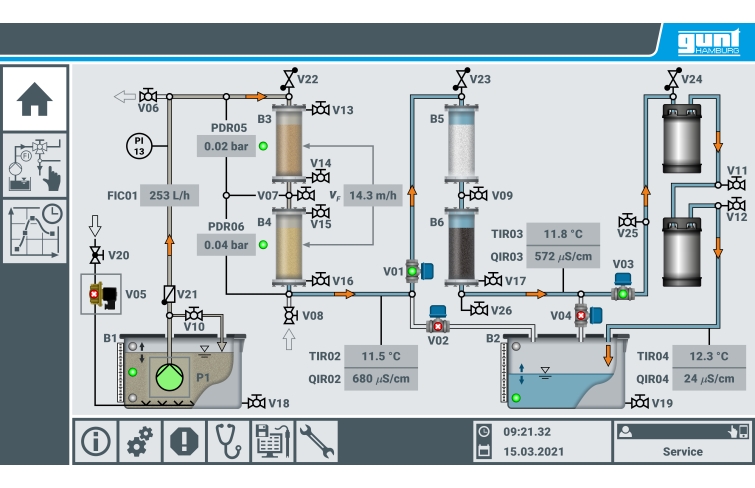

The raw water is pumped from above into a gravel filter and then routed into a sand filter. In the process, suspended solids are removed from the raw water. The filtered water then flows into the second treatment stage. There dissolved substances are removed by adsorption on aluminium oxide and on activated carbon. Then the water passes on to the third treatment stage. In this stage unwanted ions are removed from the water by ion exchange. First the water is softened by cation exchange. The water is then desalinated in a mixed bed ion exchanger containing cation and anion exchangers.

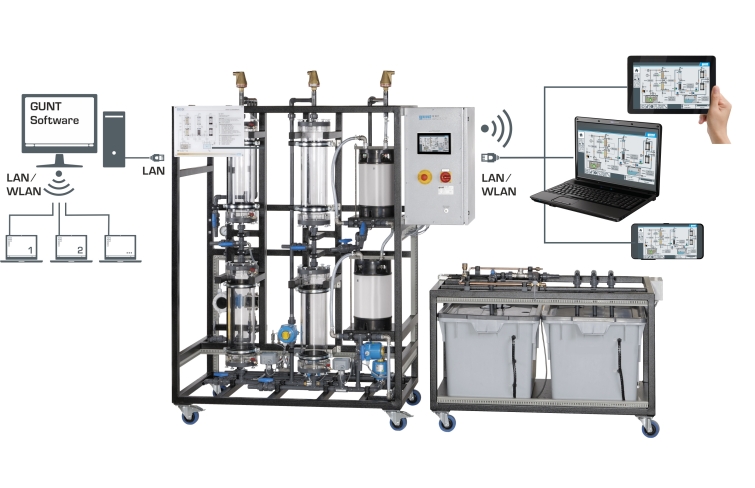

The separate supply unit includes pumps and tanks for the raw water and treated water. The raw water tank can be aerated. This ensures the raw water is mixed through. It also enables dissolved substances (such as iron) to be precipitated so as to then filter them. A connection to backwash the sand filters is provided.

The flow rate, temperature, conductivity, differential pressure and system pressure are measured. Samples can be taken at all relevant points.

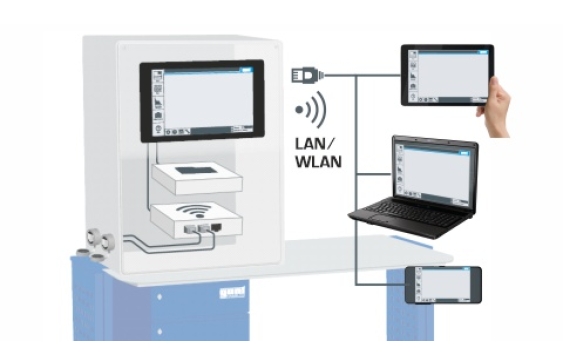

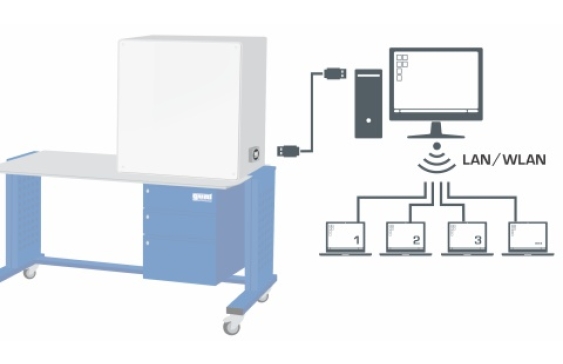

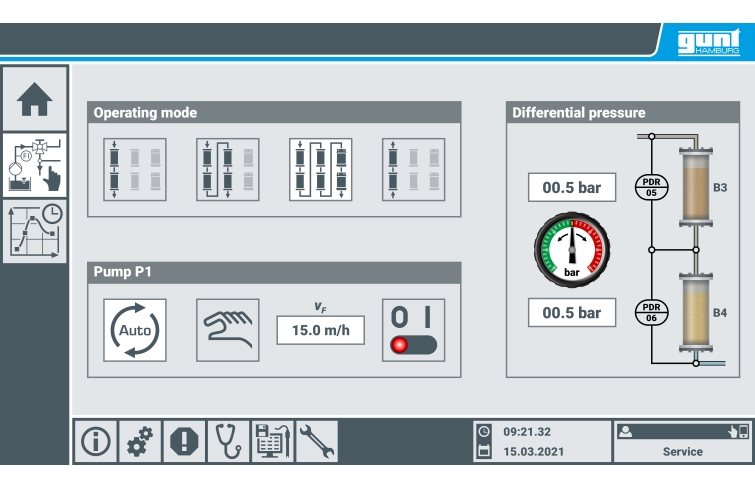

The trainer is controlled by the PLC via touch screen. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on additional end devices (screen mirroring). Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/LAN connection to the customer’s own network. Via direct LAN connection the measured values can also be transmitted to a PC where they can be analysed using the GUNT software.