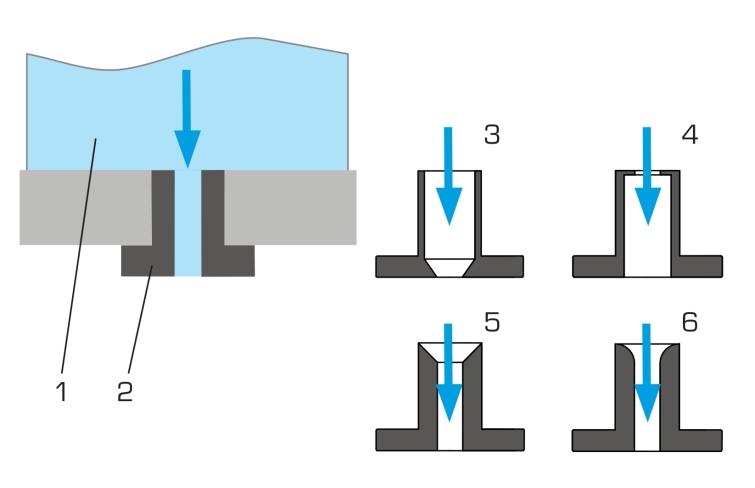

Pressure losses in the flow from tanks are essentially the result of two processes: the jet deflection upon entry into the opening and the wall friction in the opening. As a result of the pressure losses the real discharge is smaller than the theoretical flow rate.

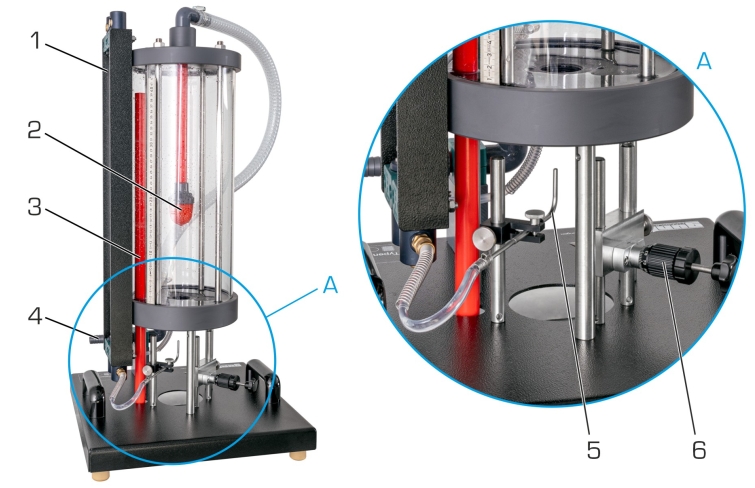

HM 150.12 determines these losses at different flow rates. The experimental unit includes a transparent tank, a measuring device as well as a Pitot tube and twin tube manometers. An interchangeable insert is installed in the tank’s water outlet to facilitate the investigation of various openings. Five inserts with different diameters, inlet contours and outlet contours are provided along with the unit.

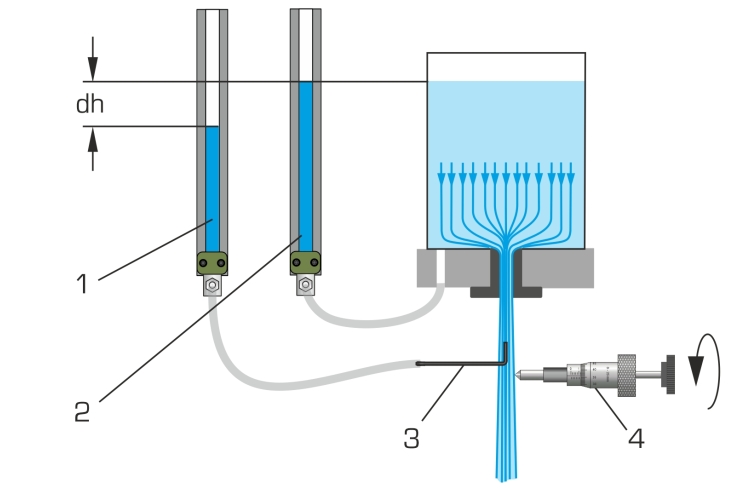

The issued water jet is measured using a measuring device. A Pitot tube detects the total pressure of the flow. The pressure difference (read on the manometer) is used to determine the velocity. Additionally, the discharge coefficient can be determined as a characteristic for different contours.

The tank is fitted with an overflow and a measuring point for static pressure. Via a gate valve in the inlet, the level can be precisely adjusted and read on the manometer. The experimental unit is positioned easily and securely on the work surface of the HM 150 base module. The water is supplied and the flow rate measured by HM 150. Alternatively, the experimental unit can be operated by the laboratory supply.

In order to perform a virtual analysis of flow behaviour, CFD simulations are often used in practice. Such simulations allow, for example, flow visualisations in areas that cannot be visualised experimentally. In the GUNT Media Center, flow visualisations based on CFD calculations are available online. There are also multimedia teaching materials including E-Learning courses on basic knowledge and calculations. Videos show a complete experiment with preparation, execution and evaluation. Worksheets with solutions supplement the teaching material.