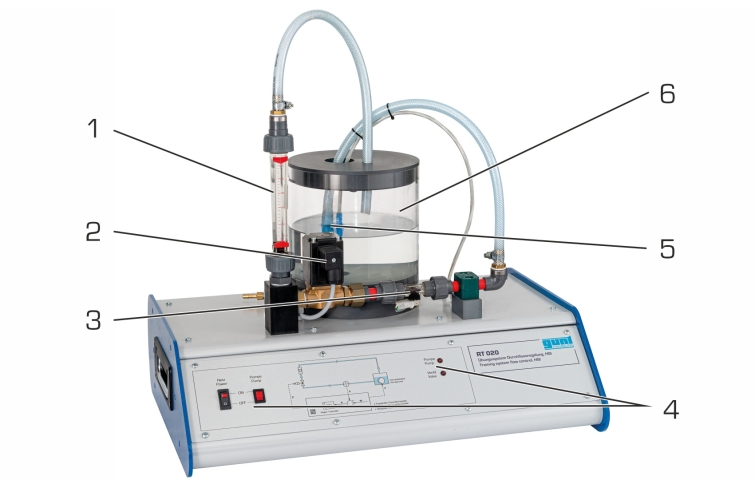

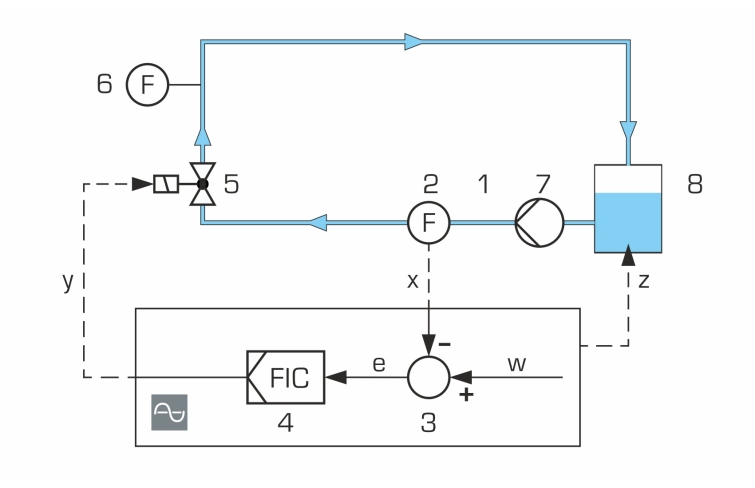

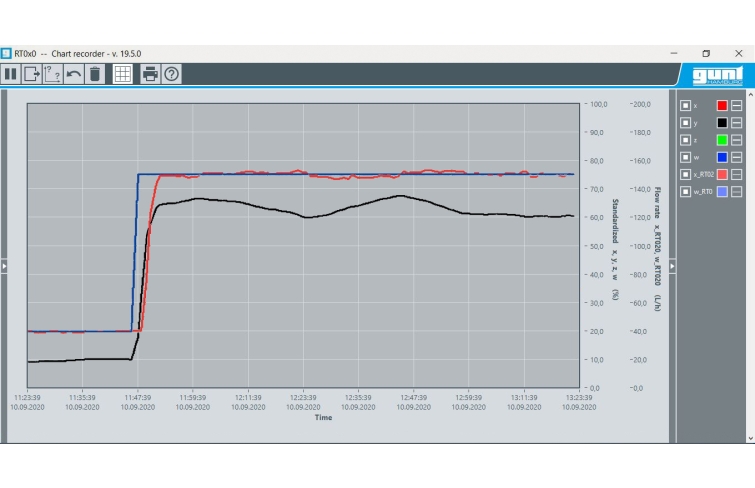

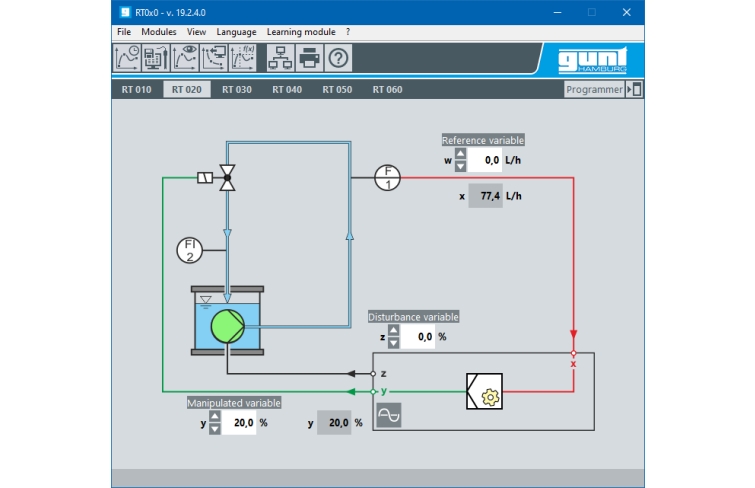

The RT 020 device offers basic experiments on a flow controlled system. A pipe section, through which media flows, serves as the controlled system. The flow rate in the pipe represents the controlled variable, which is measured by a measuring element, in this case a turbine wheel flow rate sensor. The output signal from the sensor is fed to the software controller. The output signal from the controller influences the actuator, in this case the electromagnetic proportional valve. The valve position changes the flow rate in the pipe. The pump speed – and therefore the delivery rate – can be controlled via the software in order to study the effect of disturbance variables. The control response is displayed in the form of a time dependency. There is a rotameter located inside the pipe, allowing the flow rate to be observed at any time.

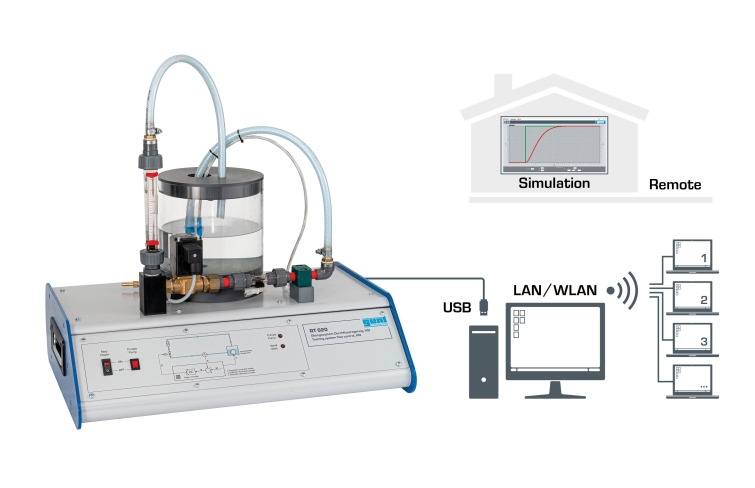

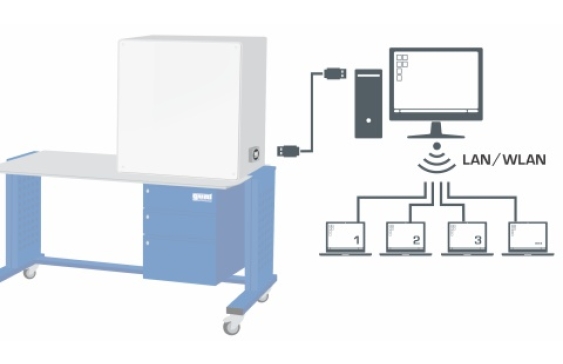

The powerful GUNT software for the entire device series – in the form of Hardware/Software Integration (HSI) – is a major component for the entire series. The experimental unit and the PC are connected via a USB interface (external PC required).

The impact that modifications to the system behaviour have can be studied quickly and easily with the help of the software. An integrated programmer allows you to set reference values and time intervals to carry out reference value progressions. Further aspects of control engineering are studied using software simulations for controlled systems up to the 2nd order.

The combination of the clear, real-world controlled system and simulations of other controlled systems in the RT 010 – RT 060 device series aids understanding. Preparations for the experiments, as well as software simulations can be carried out in Remote Learning environments. The experiments can be observed at any number of workstations on the local network.