Steam is particularly suitable as a heat transfer medium for heating fluids. The steam pressure can be used to limit the maximum temperature so that sensitive fluids can be heated safely. Tube bundles, for example, are used as heat exchangers. The steam condenses and transfers its condensation heat to the fluid being heated. The condensate can then be returned to the steam process.

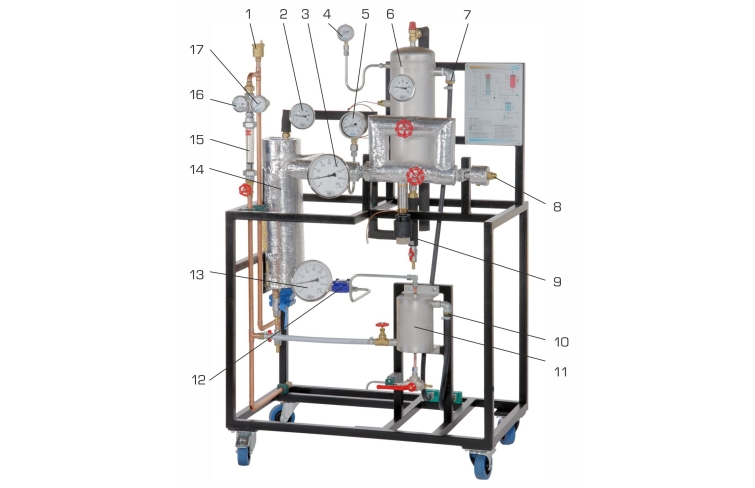

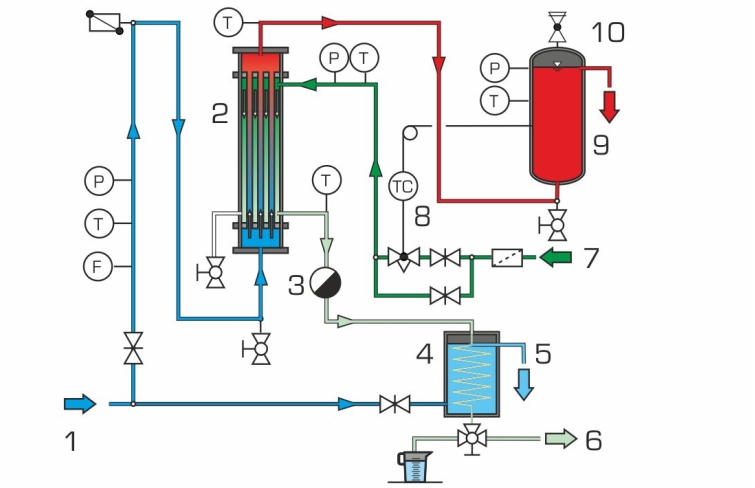

The WL 315.01 trainer is used to study the convective heat transfer between steam and water. The core element of the trainer is a shell & tube heat exchanger. Heating steam in the pipe jacket and cold water in the pipes are directed past each other in counterflow. In doing so, the heating steam emits some of its thermal energy to the cold water. The heated water flows into a tank, where it is available to be withdrawn.

In the steam pipe downstream of the shell & tube heat exchanger there is a condensate separator and a second, small heat exchanger as condenser for condensing the flash steam.

The amount of steam introduced is regulated by a thermostatic valve so that the water temperature in the hot water tank is at the desired temperature. Parallel to the thermostatic valve and shut-off valve, the heating steam can be manually directed into the shell & tube heat exchanger by means of a manual valve. The flow rate in the cold water circuit can be adjusted.A strainer at the heating steam inlet protects against coarse particles in the steam pipes. The hot water tank is fitted with a safety valve to protect the system from positive pressure.

By measuring temperatures, pressures, flow rate and condensate quantity, it is possible to determine the energy, efficiency and overall heat transfer coefficient.

The heating steam is supplied by means of the accessory WL 315.02.