Pumps belong to the group of driven machines. Their task is to transport incompressible fluids. Pumps are categorised into rotodynamic pumps and positive displacement pumps, depending on their principle of operation.

Rotodynamic pumps transfer energy to the fluid with the help of blades arranged on an impeller. The blades are shaped in a way that the flow around them causes a pressure difference between the inlet and outlet side.

Positive displacement pumps move the pumping medium by changing the volume and by opening and closing inlets and outlets correspondingly. Depending on the design of the displacement device the volume changes through oscillating or rotating movements. Rotodynamic pumps, such as centrifugal pumps, are of advantage where large flow rates are required, while positive displacement pumps, such as piston pumps, are better suited for smaller flow rates with a high head.

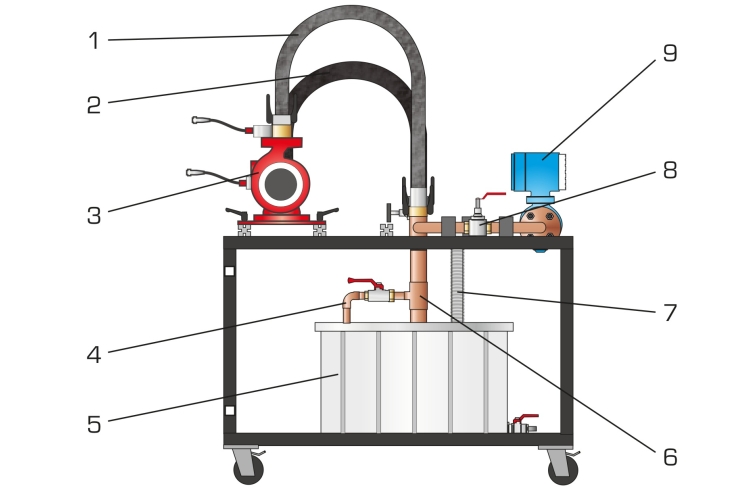

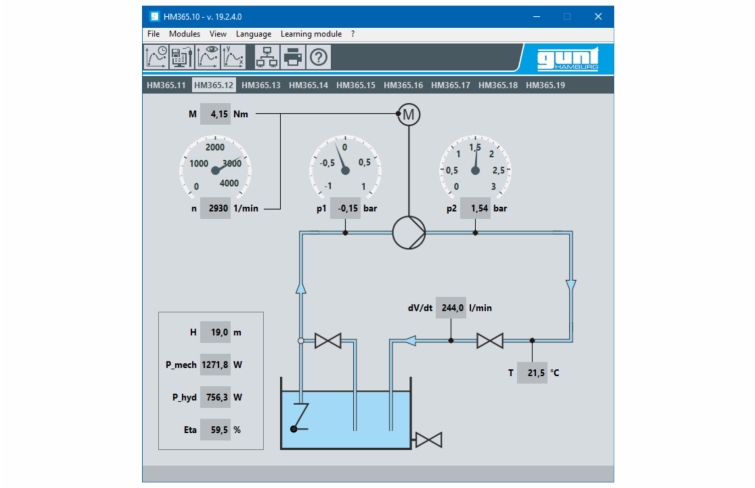

The supply unit HM 365.10 supplies the working medium water for several centrifugal pumps and positive displacement pumps (HM 365.11 to HM 365.19). The pumps are powered in conjunction with the HM 365 Universal Drive and Brake Unit.

The trainer works independently of the water supply network, using a closed circuit with a storage tank. The individual pumps are placed on the work surface and connected by means of hoses with quick-release couplings, and attached with clamping levers. The pump is connected to the drive unit, which provides it with power via a V-belt.

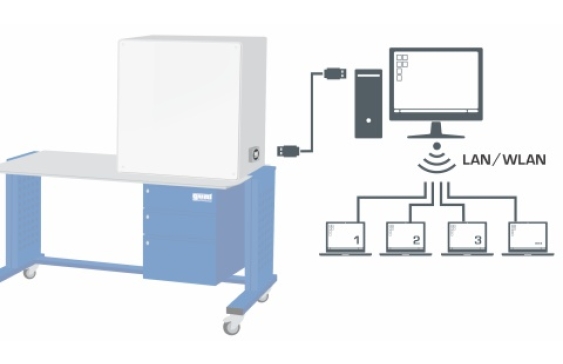

The flow rate is measured with an electromagnetic flow rate sensor. A temperature sensor records the temperature in the piping system. Each pump is equipped with pressure sensors for measuring the pressure. The measured values are read from digital displays on the supply unit and can be transmitted simultaneously via USB directly to a PC, where they can be analysed using the included software.