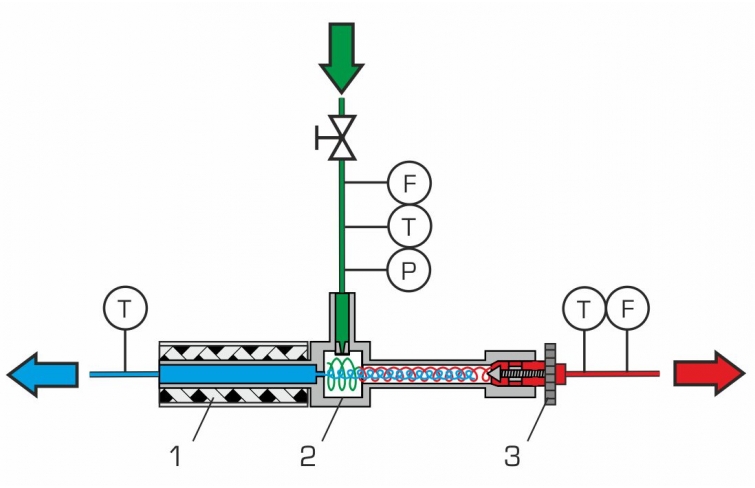

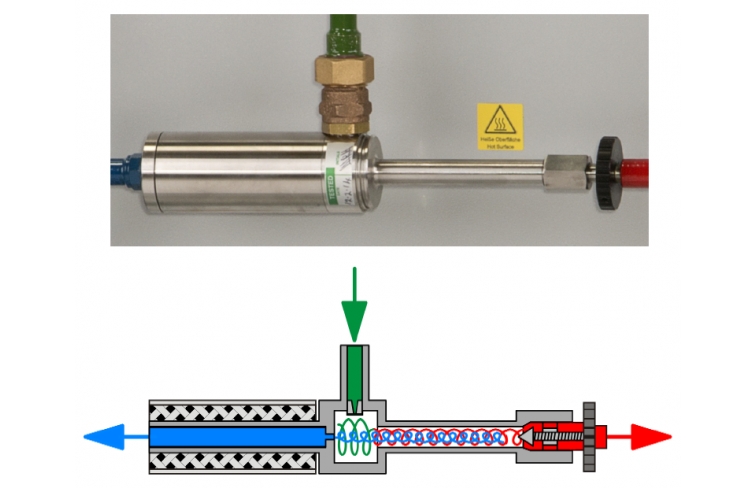

The experimental unit ET 122 generates cold and hot air with the aid of ordinary compressed air. The central element of the experimental unit is a vortex cooling device also known as a vortex tube. In the vortex tube the tangentially incoming compressed air is moved in rapid rotation. This creates a cold and hot air flow in the vortex tube which leaves the vortex tube at opposite ends.

A vortex cooling device does not have any moving parts, is maintenance-free and immediately ready for operation.

The vortex cooling device is used for the convective cooling of high-speed tools, the air conditioning of protection suits and the cooling of switch cabinets. It is particularly suited for use in explosive environments. One benefit here is that the vortex cooling device does not require an electric power supply.

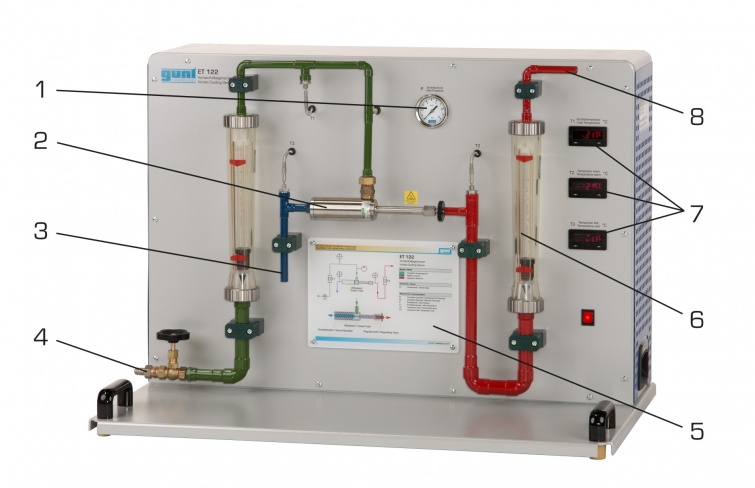

The inlet pressure is measured using a manometer. The compressed air volume and the outlet volume of the hot air flow are each measured using a rotameter. The inlet temperature of the compressed air and the outlet temperatures of the cold and hot air flows are displayed digitally.