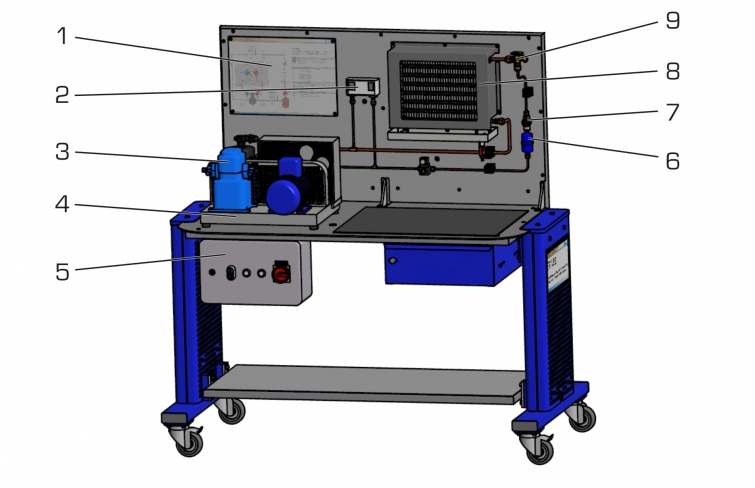

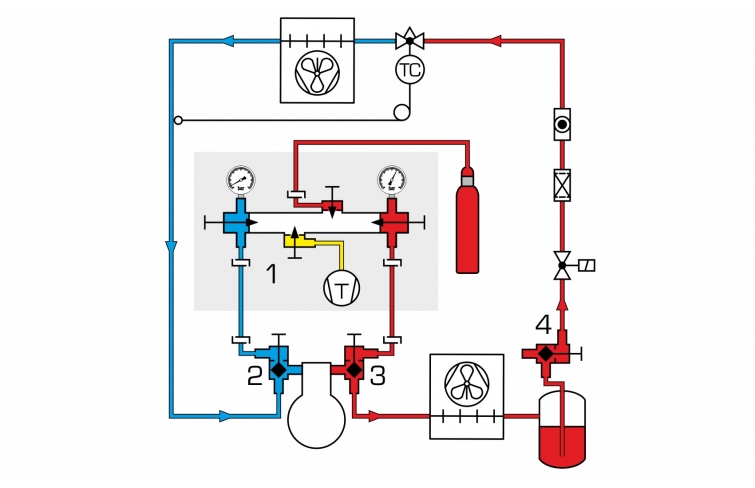

The replacement of a faulty compressor or other components of the refrigeration system are amongst the repeated activities of a mechatronics engineer for refrigeration. ET 192 allows for training in these processes. The consequences of incorrect procedures can be demonstrated.

The components are integrated into an operational refrigeration system. This allows for the practical testing of the functionality of individual components after replacement. The following activities must be carried out e.g. after replacing a compressor:

- refrigerant displacement (pump-down) into the condenser/receiver (should this not be possible, siphoning off the refrigerant)

- disconnection of the compressor at the service valves

- disconnection of electrical connections

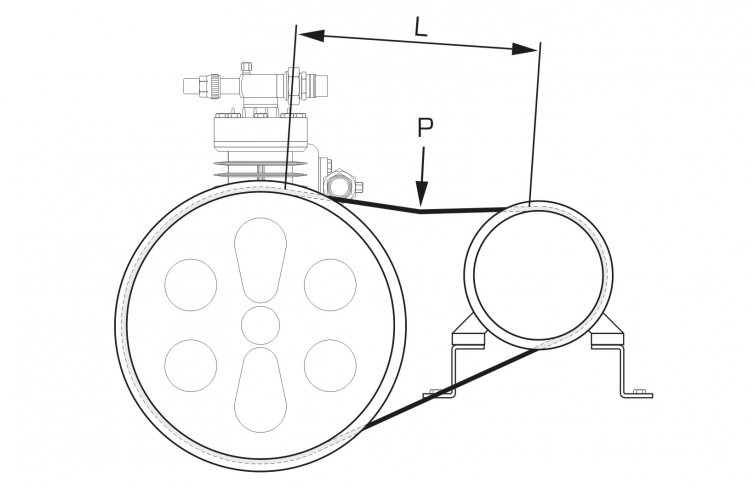

- compressor replacement, correcting oil level, if necessary

- reconnecting electrical connections

- reconnecting the compressor with the service valves

- evacuating the compressor and making the connection to the system

- compressor test run, checking for leaks and replenish refrigerant, if necessary

- checking the system pressures

To carry out the service tasks, the tool set ET 150.02 and the filling and evacuation equipment ET 150.01 are required.