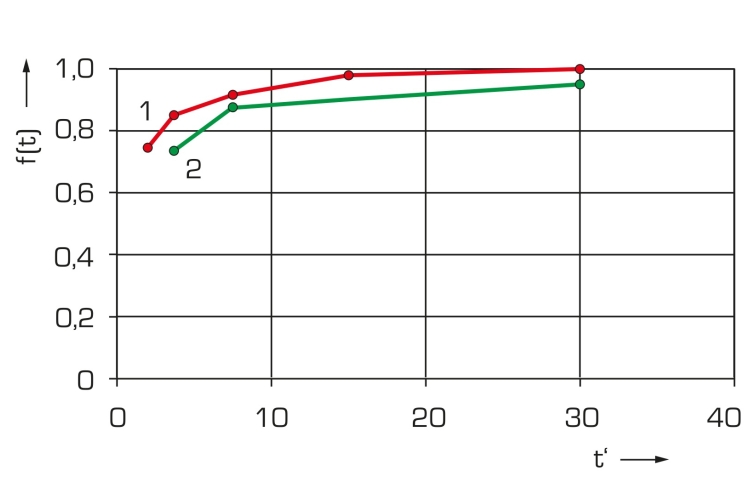

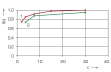

Stirred tanks in series are, as the name says, continuous stirred tank reactors connected in series. They enable a higher conversion than a single stirred tank reactor. Stirred tanks in series enable flexible process control as the temperature and retention time can be set separately for each individual reactor.

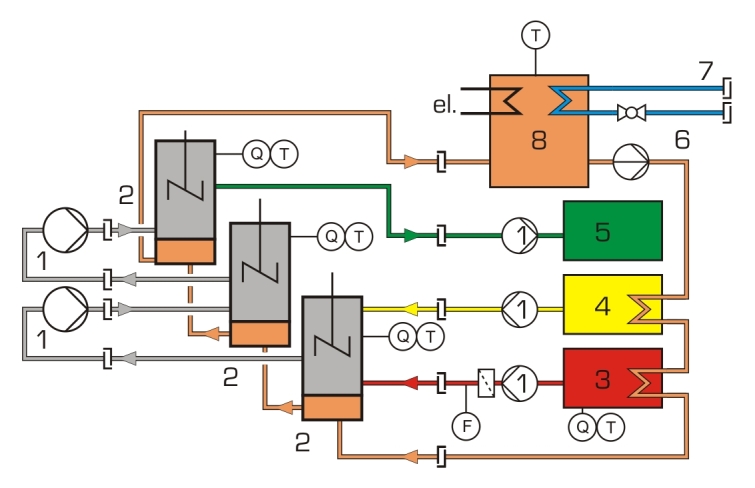

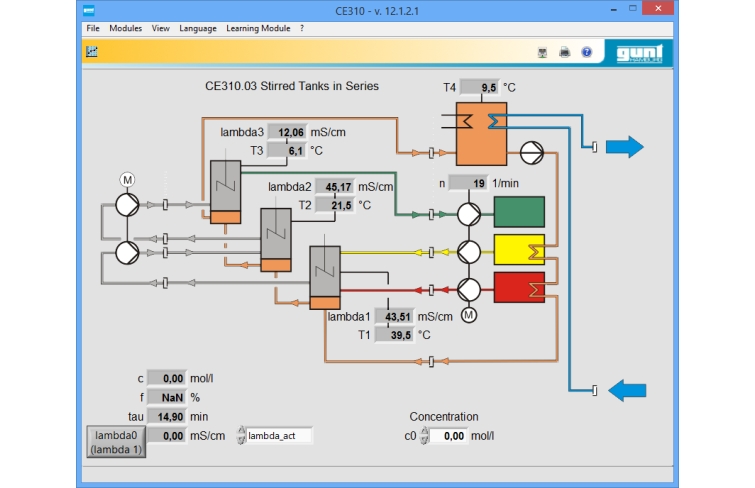

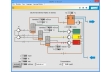

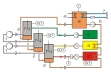

CE 310.03 is part of a device series that enables experiments with different reactor types. In conjunction with the supply unit CE 310, it is possible to examine the function and behaviour of stirred tanks in series. The supply unit CE 310 has a heating water circuit as well as all necessary connections, pumps, tanks for reactants and a product tank.

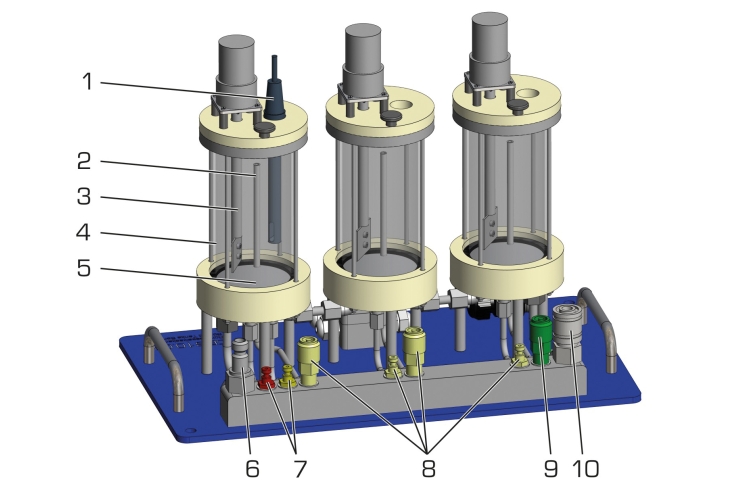

CE 310.03 is mounted onto the supply unit and held by two pins in position. Quick-release couplings enable easy connection of the reactor to the supply unit.

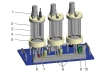

In continuous three-stage operation, two pumps of the supply unit deliver the reactants into the first reactor. A stirrer ensures a homogeneous mixture and thus increases the direct contact of the reactants. The product is formed by reaction of the reactants. The mixture of product and unconverted reactants leaves the reactor through an overflow and is then delivered into two further identical reactors one after the other. The intermediate delivery occurs via 2 further peristaltic pumps of the supply unit. After the third reactor the transport occurs in a tank of the supply unit.

The retention time of the reactants in the reactor is adjusted via the speed of the pumps on the supply unit.

The conversions in the individual reactors is determined by measuring the conductivity. A combined conductivity/temperature sensor is included. Conductivity and temperature are digitally displayed on the switch cabinet of the supply unit. In addition, the measured values can be captured and processed with data acquisition software (included in CE 310).