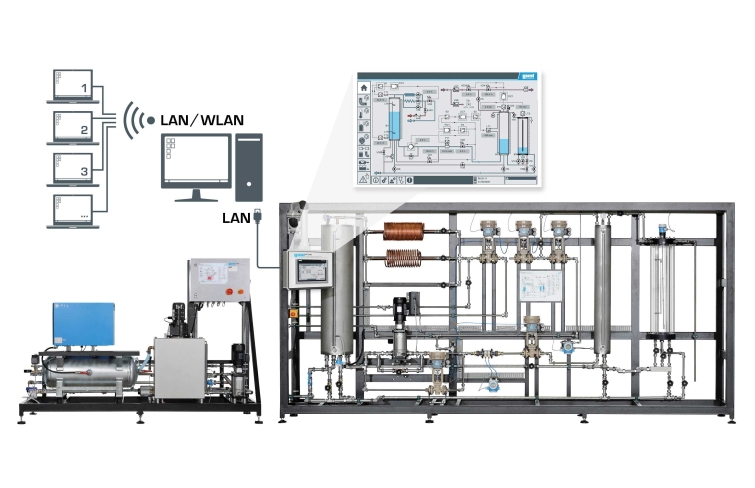

The supply of processes with media such as water and compressed air in industry is usually provided from a separate, centralised supply unit. Control and monitoring of the processes are also centralised. RT 590 represents such a practical scenario. The experimental plant includes a separate supply unit and a trainer with touch screen for controlling and monitoring the processes.

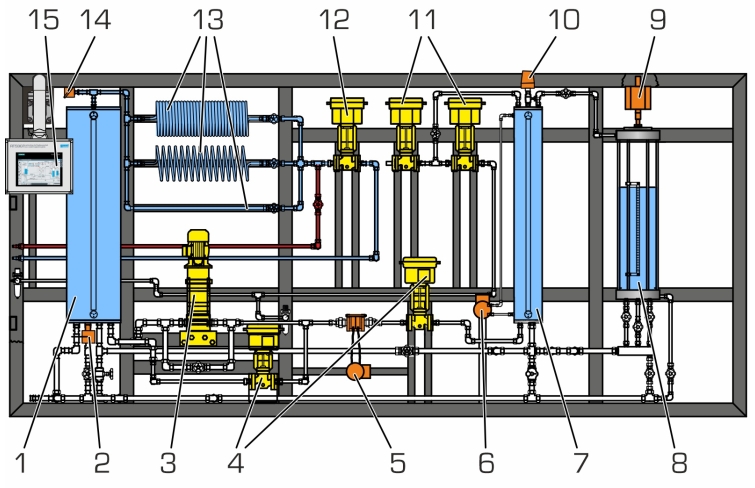

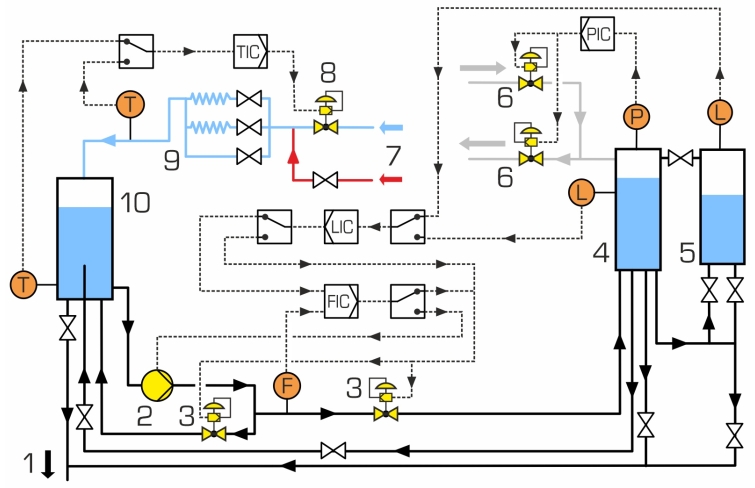

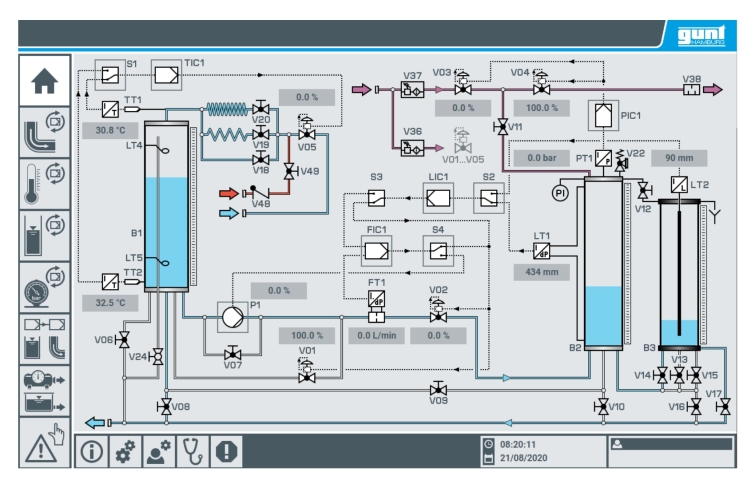

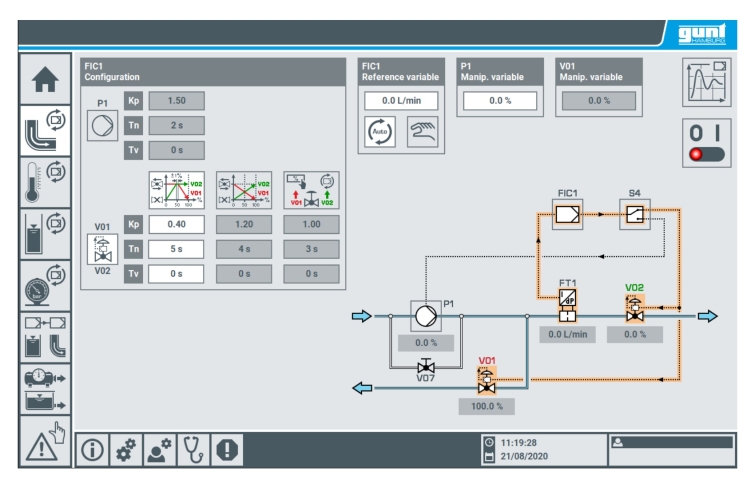

The trainer includes a water circuit with a pump, collecting tank and graduated tank. In this circuit, the flow rate and level are controlled. Electropneumatic control valves are used as actuators. The speed-controlled pump with frequency converter can also be used for flow control. The level control can also be executed under counter pressure or as cascade control. A transparent tank can be connected to facilitate learning with a second order level controlled system.

For pressure control compressed air is used as working medium. The graduated tank serves as the controlled system. The level of liquid in the tank can be varied to give time-varying response of the controlled system.

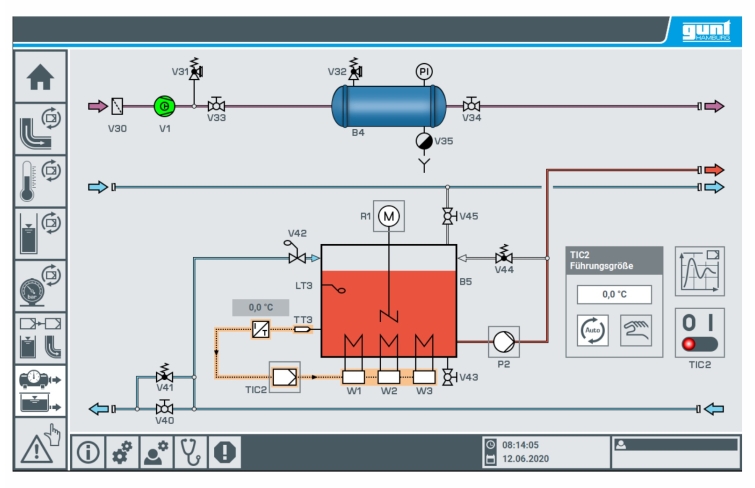

The temperature is controlled either in the collecting tank or in the inlet of the tank. For this purpose, cold water is added to the warm water in the inlet via a control valve. Three delay sections are used to set different dead times.

In addition, the experimental plant enables practical fault analysis based on simulated typical faults such as cable break, frozen measured values or a reduced setting range.

The plant is operated and controlled by the integrated PLC with touch screen or by a PC with GUNT process control software. The time functions of the process variables are displayed and the controllers are parameterised. The GUNT process control software enables the data acquisition. Any number of workstations with the GUNT process control software can be used for observation and evaluation of the experiments via LAN/ WLAN connection using only one licence.