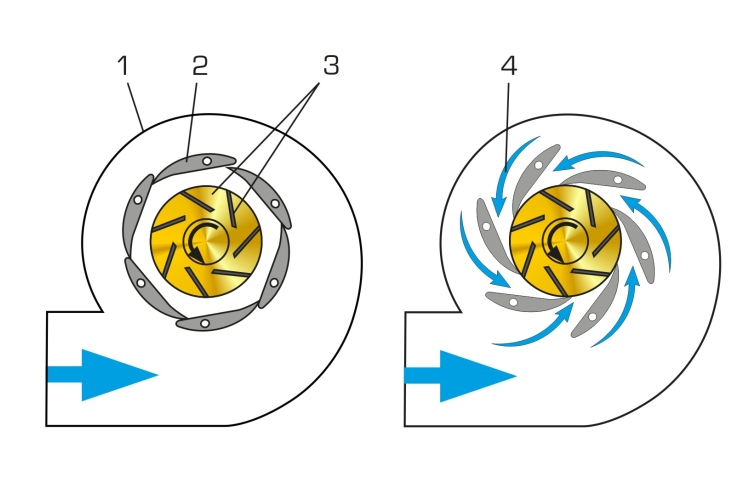

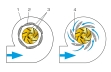

The Francis turbine is a type of reaction turbine which converts the pressure energy of the water into kinetic energy in the distributor and in the rotor. The water is fed in the distributor by means of a spiral housing. The flowing water is accelerated in the distributor by the adjustable guide vanes and directed onto the blades. The redirection and further acceleration of the water in the rotor generates an impulse which is transmitted to the rotor.

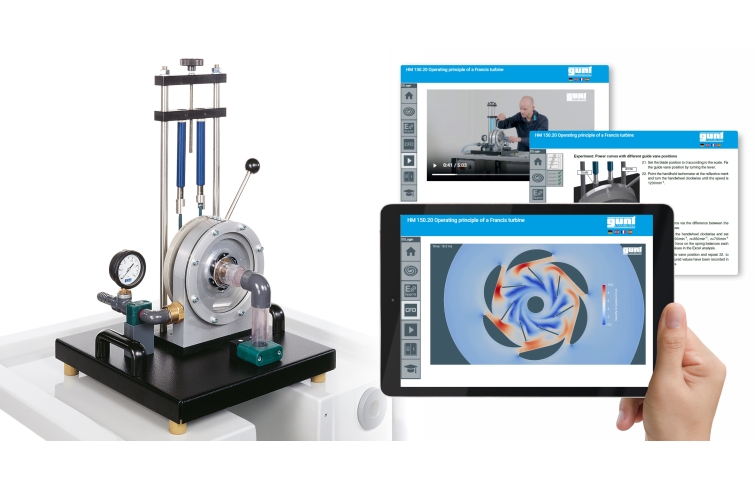

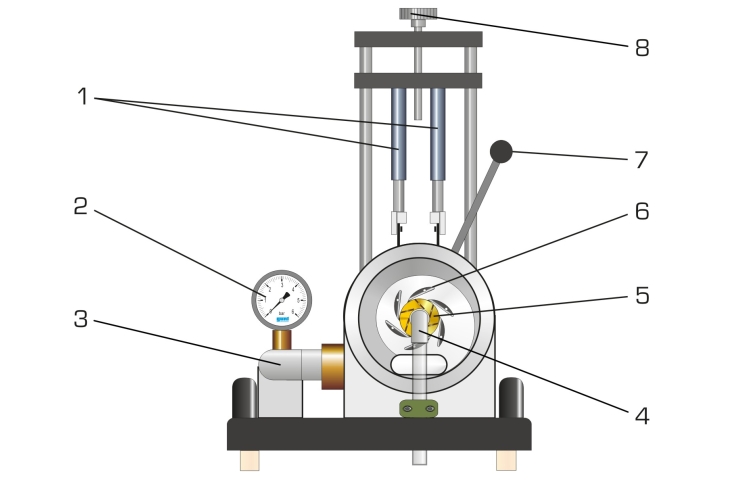

HM 150.20 is the model of a Francis turbine demonstrating the function of a reaction turbine. The experimental unit consists of the rotor, the distributor with adjustable guide vanes, a band brake for loading the turbine and a housing with a transparent front panel. The transparent cover enables to observe the water flow, the rotor and the guide vanes during operation. The angle of attack and thus the power of the rotor are modified by adjusting the guide vanes.

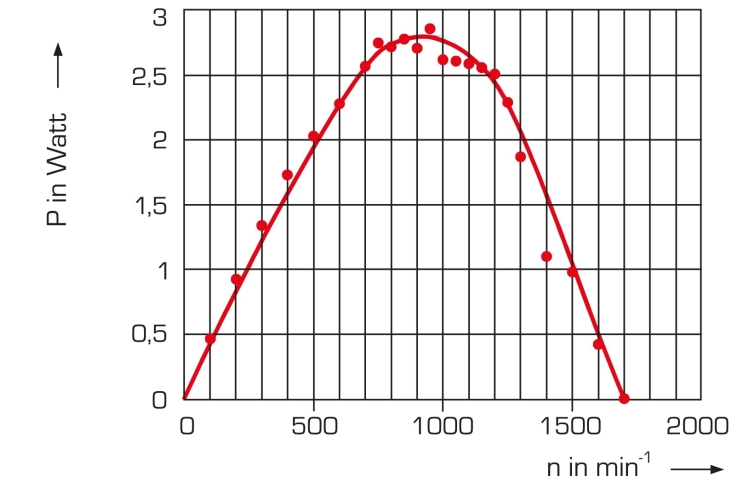

The turbine torque is determined by force measurement on a band brake and is read on spring balances. For measuring the rotational speed, a non-contact speed sensor, e.g. HM 082, is required. A manometer shows the water pressure at the turbine inlet.

The experimental unit is positioned easily and securely on the work surface of the HM 150 base module. The water is supplied and the flow rate measured by HM 150. Alternatively, the experimental unit can be operated by the laboratory supply.

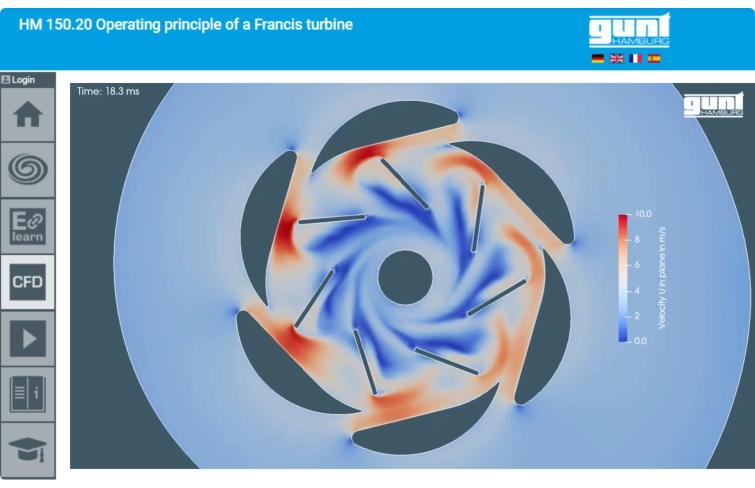

In order to perform a virtual analysis of flow behaviour, CFD simulations are often used in practice. Such simulations allow, for example, flow visualisations in areas that cannot be visualised experimentally. In the GUNT Media Center, flow visualisations based on CFD calculations are available online. There are also multimedia teaching materials including E-Learning courses on basic knowledge and calculations. Videos show a complete experiment with preparation, execution and evaluation. Worksheets with solutions supplement the teaching material.