The MT 142 test device is used together with the MT 141 piston compressor assembly exercise. The fully assembled piston compressor is placed in the test device. This is where the entire system is professional assembled, including alignment of the drive motor and piston compressor. A successfully completed assembly project can then be concluded with a formal final test.

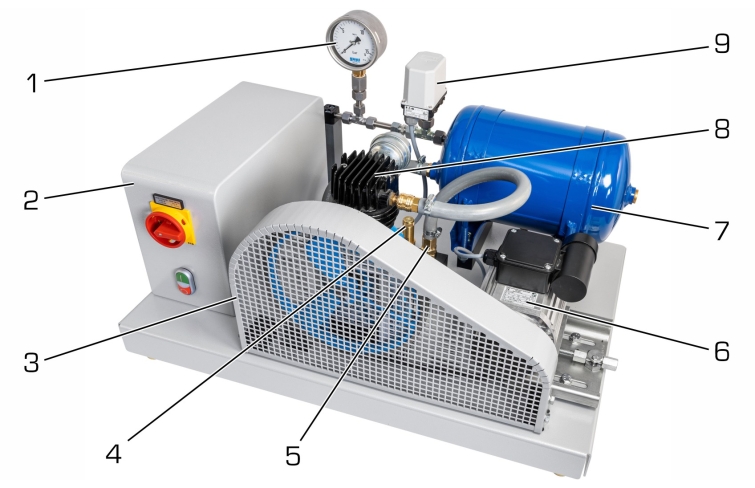

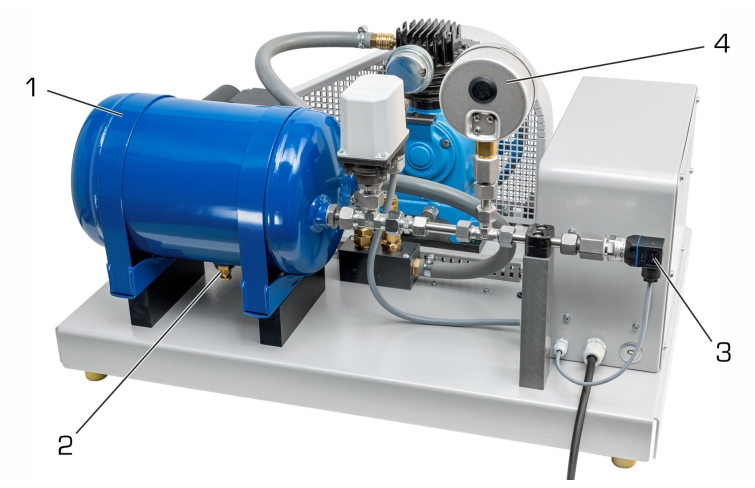

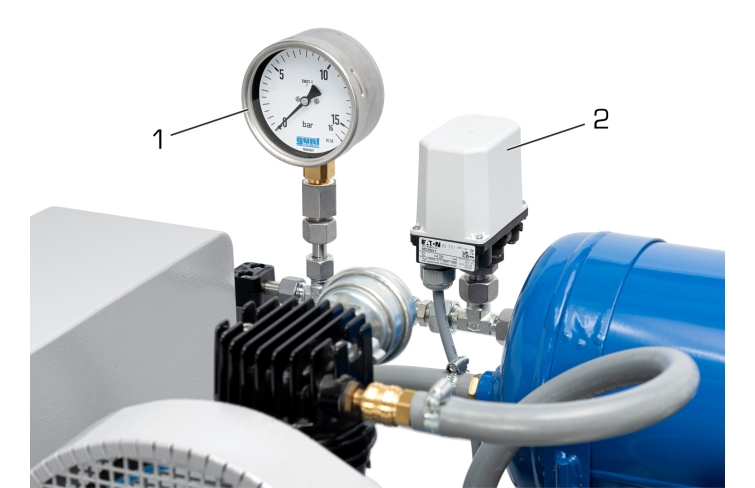

The test device contains an electric motor with belt pulley as the drive, a compressed air tank with pressure indicator, safety valve and pressure monitor. The fully assembled piston compressor (MT 141) is installed in the test device and connected to the drive motor via a belt drive. A protective grid prevents accidental contact with the rotating parts.

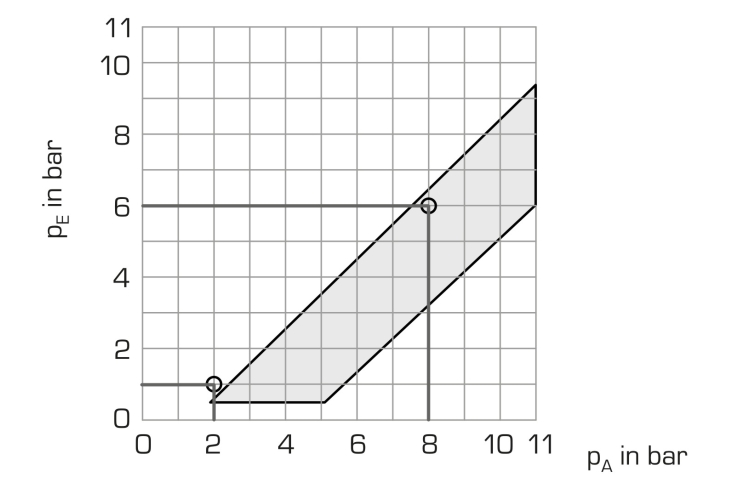

During the functional test, the pressure increase in the compressed air tank and the electric power of the electric motor are recorded over time. A pure functional test can be carried out without using the software.

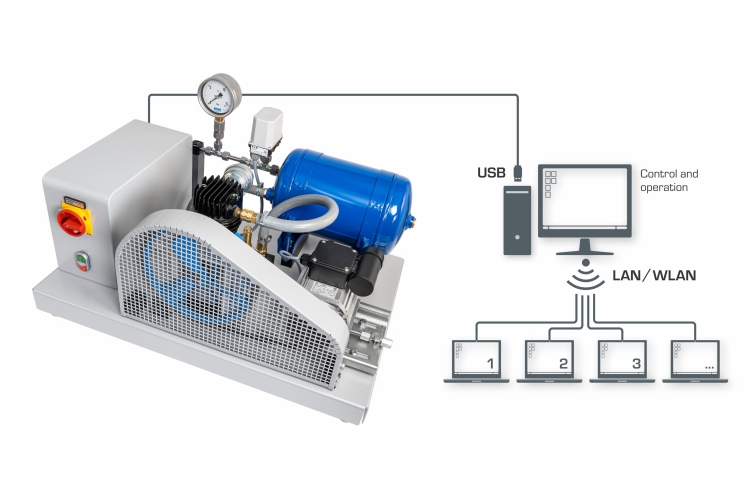

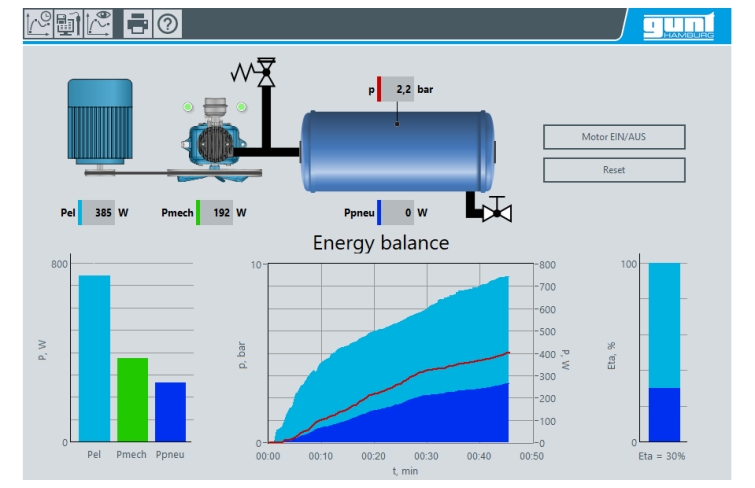

When used in conjunction with the GUNT software, it is possible to create an energy balance. To do this, the electrical power, mechanical power and pneumatic power are recorded over time while the device is running. The efficiency is then calculated from the energy absorbed. The measured values are transmitted directly to a PC via USB where they can be displayed graphically using the software included.

In the GUNT Media Center, extensive technical information is available as didactic multimedia teaching materials, such as animations of the function, tasks and solutions.