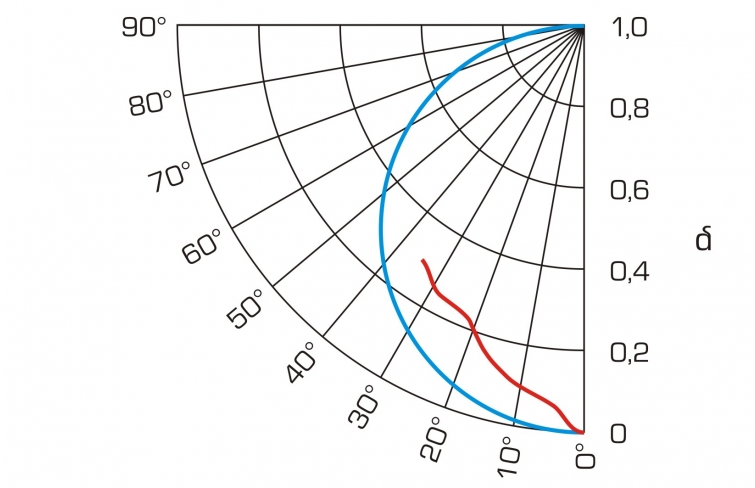

In hydrodynamic bearings, the shaft and the bearing shell are separated from each other during operation by a supporting lubricating film. The pressure in the lubricating film in hydrodynamic journal bearings is generated by the relative motion between bearing shell and shaft. The position of the shaft in relation to the speed and the load is important for an analysis of the tribological process in the bearing shell of a journal bearing.

The TM 290 trainer allows the study of a hydrodynamically lubricated radial journal bearing. Five shafts with different diameters allow the operating behaviour to be analysed as a function of the bearing clearance.

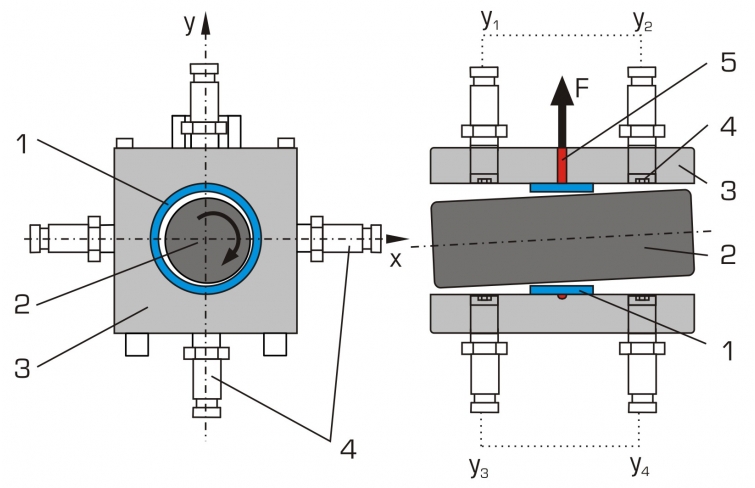

The radial load on the journal bearing is applied by means of a handwheel and measured electronically. Similarly, the frictional moment is measured using a force sensor. The shaft is driven by a three-phase motor. The speed is continuously adjustable via a frequency converter and is displayed digitally. The oil temperature is adjusted using a controller.

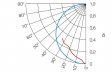

Inductive sensors detect the relative motion of the shaft in the bearing. This measurement makes it possible to plot a locus of the shaft as a function of load and speed. The position is measured, averaged and displayed at four points on the shaft in each of the X and Y directions.

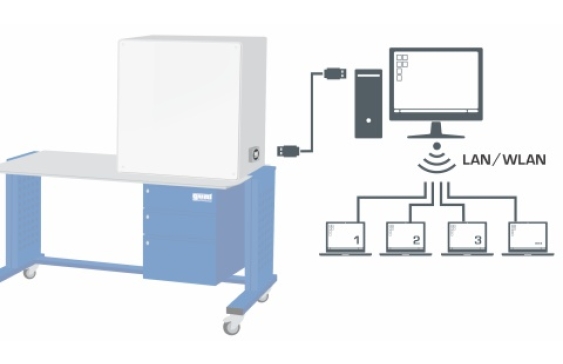

Oil temperature, oil pressure and oil peak pressure in the bearing are measured and displayed by additional sensors. The measured values are read from digital displays and can be transmitted simultaneously via USB directly to a PC where they can be analysed using the software included.