Tubular heat exchangers are the simplest type of heat exchanger and are preferably used when heat is transferred at high pressure differences or between highly viscous media (e.g. sewage sludge). One advantage is that the pipe space is flowed through evenly and is free of flow dead zones.

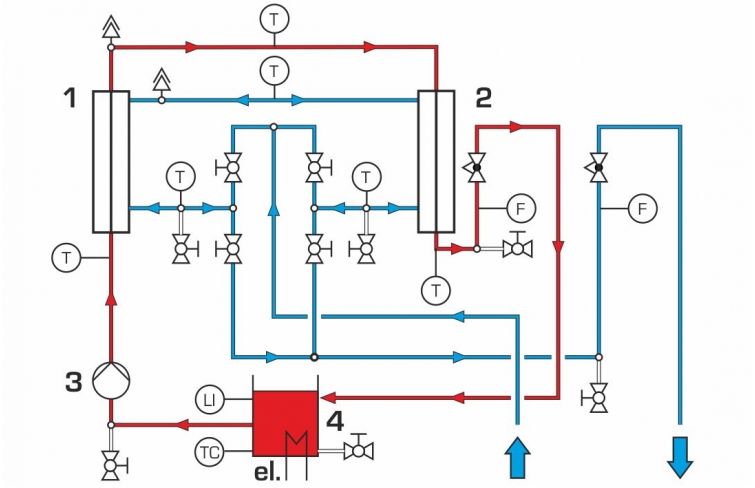

The WL 302 trainer enables the study of the characteristic properties of heat transfer on the model of a tubular heat exchanger. The heat transfer takes place in coaxially arranged tubes with the hot water passing through the inner tube. Cold water flows in the outer tube. In doing so, the hot water emits some of its thermal energy to the cold water.

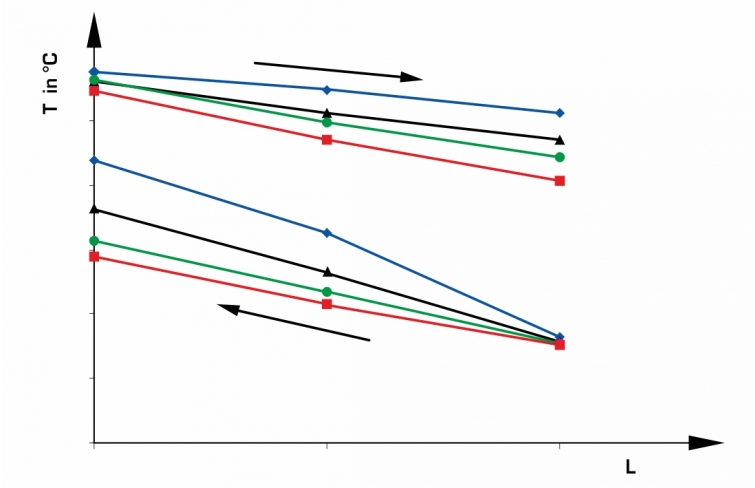

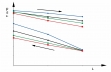

In experiments, both parallel flow and counterflow operation can be demonstrated, with their different temperature curves.

The non-linear temperature progression along the tubular heat exchanger is demonstrated by measuring the water temperatures in both tubes at the inlet, outlet and half of the transfer section. A measurement of the pipe wall temperature also allows the investigation of convective heat transfer at the wall. In the experiment analysis, the important variables such as heat flux, overall heat transfer coefficient and heat losses are determined.

The closed hot water circuit contains a tank with electrical heater and a pump. A thermostat keeps the hot water temperature constant. The cold water is supplied and disposed of via the laboratory network.

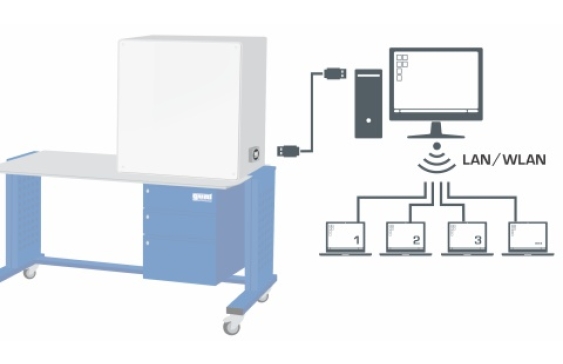

The flow rate and all relevant temperatures are recorded. The measured values are read from digital displays and can be transmitted simultaneously via USB directly to a PC, where they can be analysed using the software included.