In many industrial production processes, as well as in the air conditioning of buildings, heat transfer takes place with the assistance of air flow. In these cases, convective heat transfer is determined by the temperature differences of the media involved and the flow.

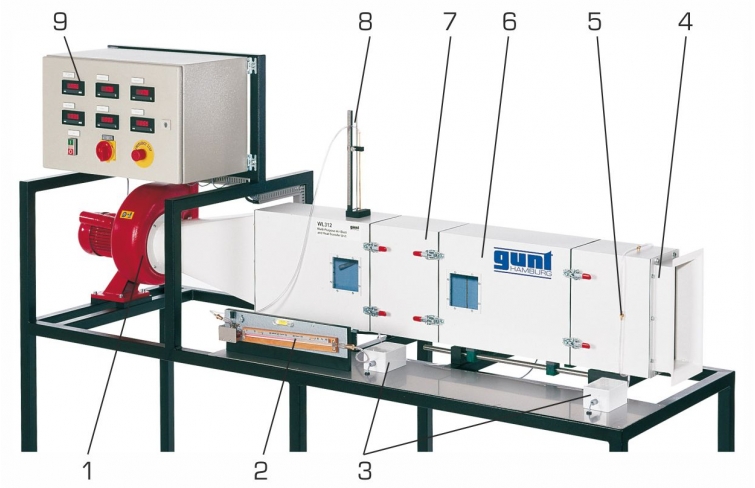

The WL 312 trainer studies convective heat transfer on various pipe surfaces. The flow movement takes place by forced convection.

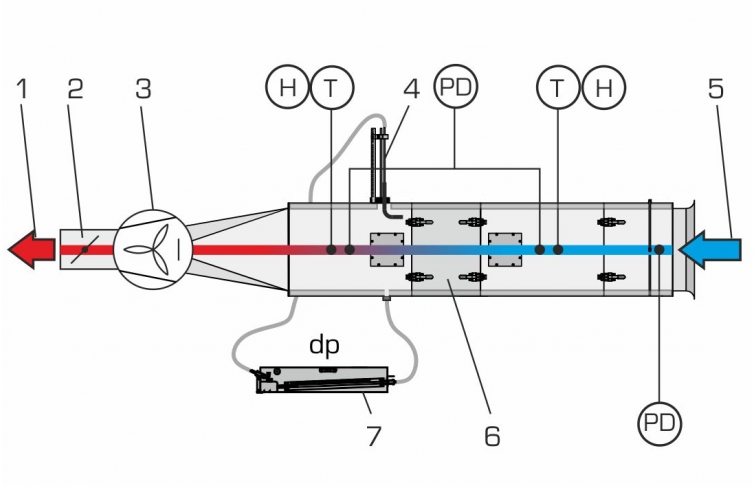

An insulated air duct with fan serves as the measuring section. A streamlined inlet element and a flow straightener in the air duct provide a homogeneous flow for conducting the experiment. The volumetric flow rate is set via a throttle valve at the fan outlet and measured by a measuring nozzle at the inlet into the air duct.

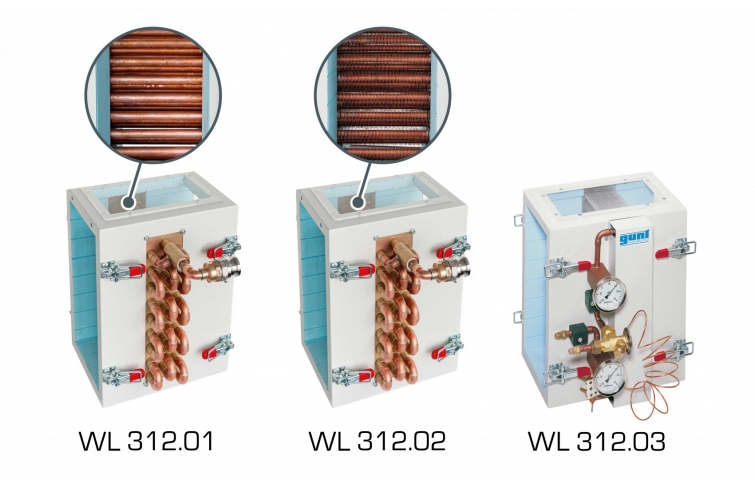

Heat exchangers with different tube surfaces can be used in the air duct. Heat exchangers with smooth tubes, finned tubes or a refrigerant evaporator are available as accessories. The air duct includes two windows to observe the experiments.

Combined sensors measure the temperature and relative humidity at the inlet and outlet of the heat exchanger. Pressures upstream and downstream of the measuring section are also recorded in order to determine the pressure loss at the heat exchanger. The velocity distribution in the air duct is measured by a Pitot tube. The temperatures, pressures and relative humidity are displayed digitally.

The following accessories are recommended for supplying the heat exchangers: Hot water generator (WL 312.10), water chiller (WL 312.11) and condensing unit (WL 312.12).