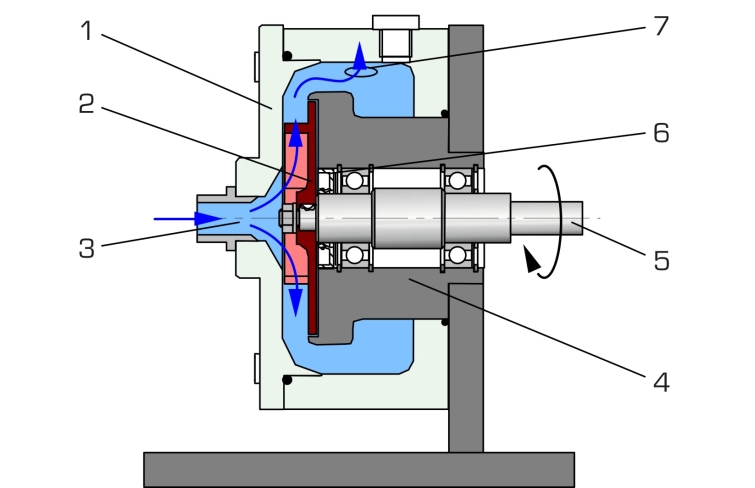

One of the most common causes of cavitation effects are fast moving objects in the water, such as the impellers of a centrifugal pump. If cavitation occurs on the impeller, the high mechanical stress sometimes results in separation or deformation of particles from the surface. In addition to the impeller geometry, intake pressure and temperature are also relevant for the occurrence of cavitation.

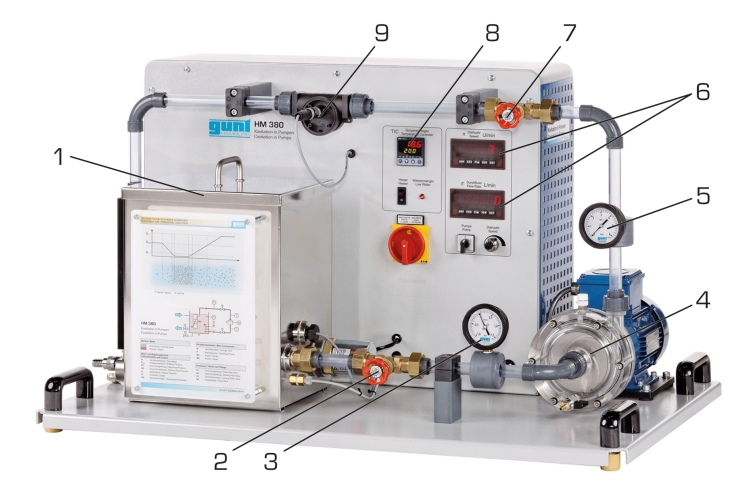

The HM 380 unit can be used to demonstrate cavitation effects on impellers of centrifugal pumps. Pump housing and the pipe at the inlet side of the pump are made of transparent plastic in order to visualise the cavitation processes. It is possible to capture excellent images of the vapour bubbles by taking photographs with short exposure times (flash).

In order to influence the flow velocity at the impeller blades, the speed can be changed within a wide range via a frequency converter. Valves at the inlet and outlet of the pump enable the flow rate and pressures to be adjusted accordingly.

Pressures on the inlet and outlet side are displayed on two manometers. Also displayed are the water temperature in the tank, flow rate and pump speed. The water temperature can be controlled and the tank is fitted with a heater. The water is cooled via the water supply.