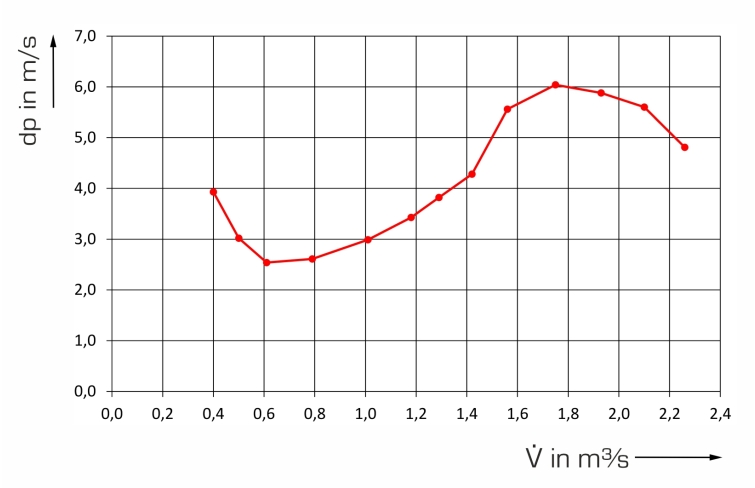

Axial fans are connected in series in plants to increase the pressure. In theory, connecting two fans in series doubles the pressure increase.

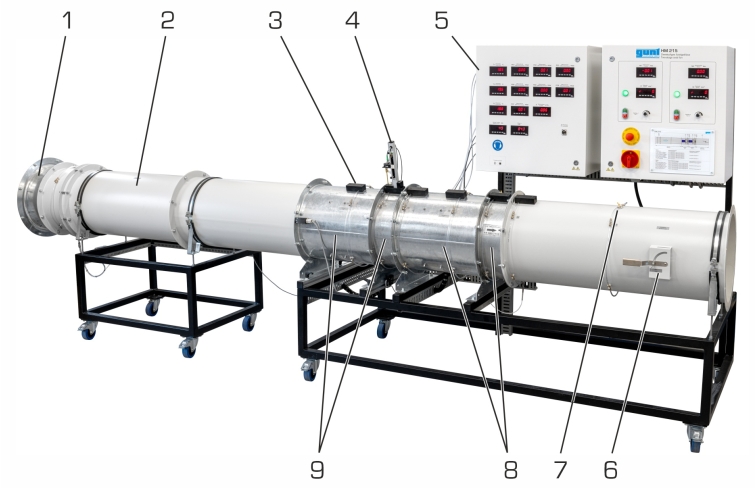

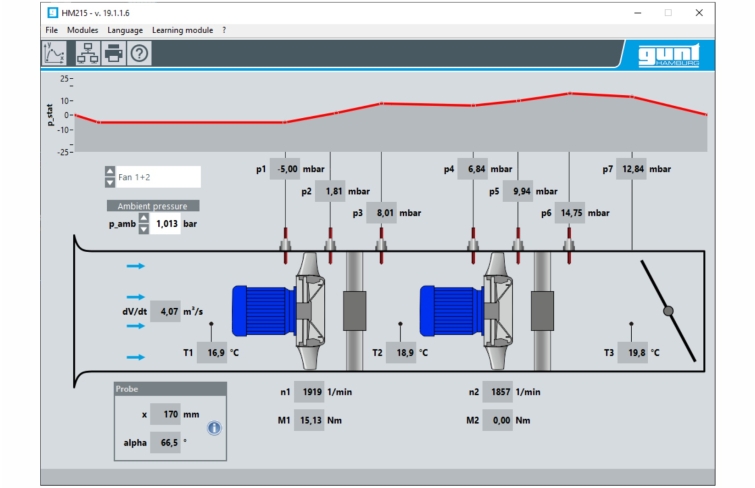

The HM 215 trainer allows the investigation of a two-stage axial fan. A measuring device is used to determine the pressure and velocity distribution.

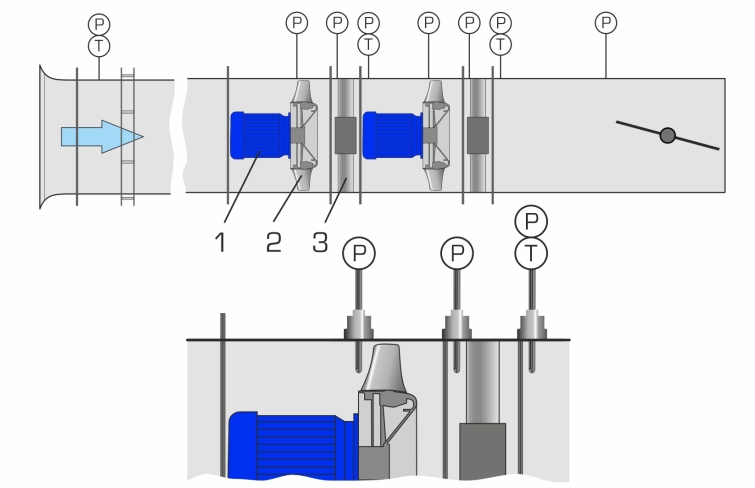

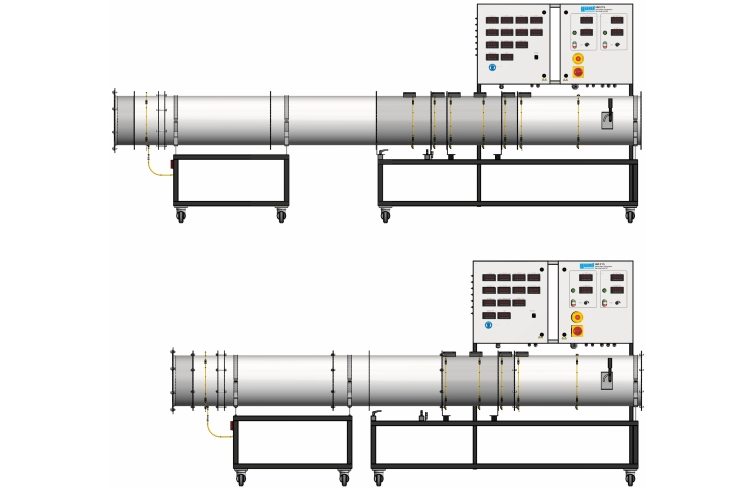

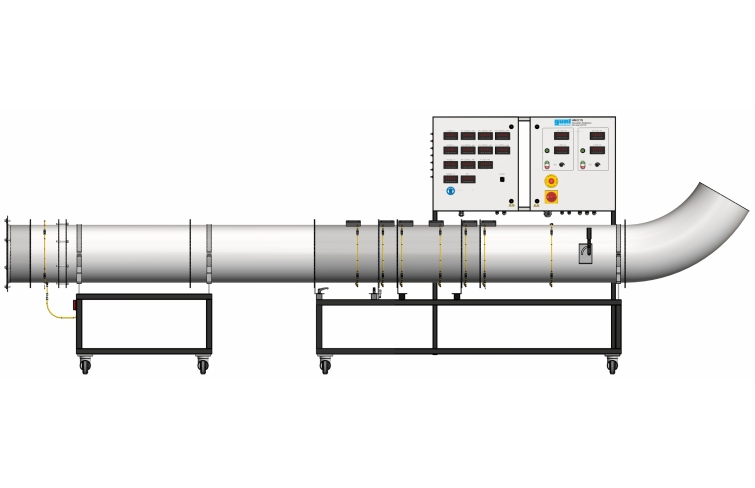

The trainer includes a measuring section with two identical axial fans. The carefully designed nozzle contour and a flow straightener at the air inlet ensure a uniform velocity distribution with little turbulence in the measuring section. The fans are equipped with outlet guide vane systems. These guide mechanisms redirect the angular momentum of the outflow in the axial direction and allow an increase in pressure. The fan speed is adjustable. A throttle valve is installed in the outlet. It can be used to adjust the air flow rate through the pipe. A pipe bend may optionally be installed to rotate the flow at the outlet of the measuring section. One of the fans can be removed from the measuring section so that the remaining fan can be studied in individual operation.

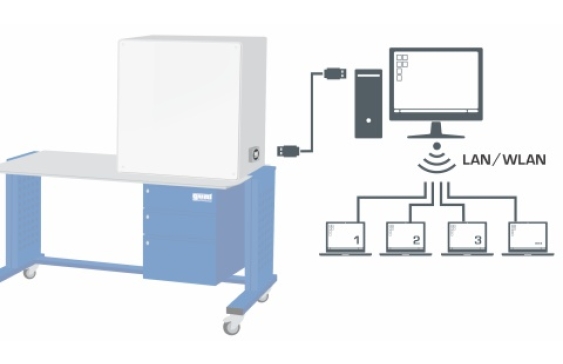

In the measuring section there are measuring connections to detect the differential pressures and temperatures. The flow rate is measured via an inlet nozzle. The differential pressure and the angle of attack are detected radially at rotors and guide vane systems by means of the 3-hole probe. This enables the display of different pressure and velocity profiles. The measured values are read from digital displays and can at the same time be transmitted via USB directly to a PC where they can be analysed using the software included.